Jul . 26, 2024 07:57 Back to list

Top Suppliers of Vertical Spindle Slurry Pumps for Efficient Material Handling Solutions

Innovative Solutions in Vertical Spindle Slurry Pump Supply

In the world of industrial pumping, the demand for efficient and reliable slurry pumps has been steadily increasing. Among various types of pumps, vertical spindle slurry pumps stand out due to their unique design and versatile applications. These pumps are especially essential in industries that handle abrasive and viscous materials, such as mining, mineral processing, and wastewater treatment.

Vertical spindle slurry pumps are engineered to handle the challenging conditions presented by slurries, which are mixtures of solids and liquids. Their design typically incorporates a vertical orientation that allows for easy installation in confined spaces and facilitates the movement of slurry from low to high elevations. This makes them ideal for applications that require high suction lift capabilities.

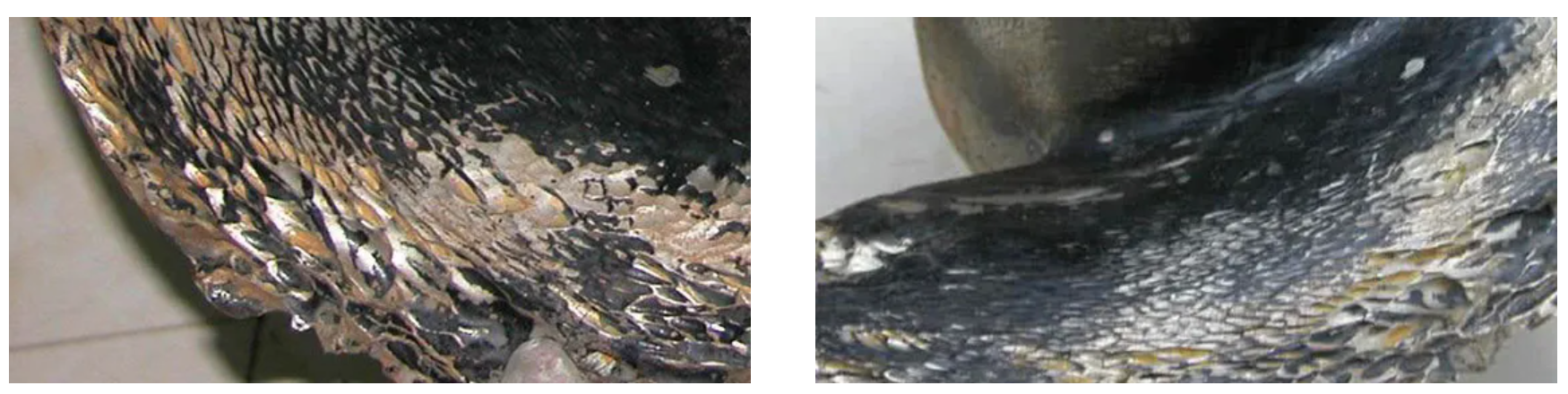

The construction of vertical spindle slurry pumps typically includes a robust casing, wear-resistant impellers, and various materials designed to withstand erosion and corrosion. Suppliers in this market focus on providing pumps made from advanced materials such as high-chrome alloys, rubber linings, and even ceramics, depending on the specific needs of the client. This thoughtful engineering ensures longevity and reduces maintenance costs, which is a significant concern for industries relying on continuous operations.

When searching for a reliable vertical spindle slurry pump supplier, it is essential to consider several factors. First and foremost, the supplier's reputation in the market is vital. Established suppliers with extensive experience often offer better after-sales support, which is crucial for troubleshooting and maintenance. A good supplier should also provide customizable solutions, as different industries and applications will have varying requirements in terms of performance and durability.

vertical spindle slurry pump supplier

Moreover, the technological advancements in pump design play a critical role in the efficiency of vertical spindle slurry pumps. Modern suppliers are embracing innovations such as computational fluid dynamics (CFD) modeling to enhance the hydraulic performance of their pumps. This allows for a more tailored approach, ensuring that the pumps operate at optimal efficiency in specific applications—minimizing energy consumption and improving overall productivity.

Cost-efficiency is another essential aspect that businesses must consider when selecting a vertical spindle slurry pump supplier. While initial costs are important, the total cost of ownership (TCO) should also be evaluated, including factors like energy consumption, maintenance, and expected lifespan. Choosing a more expensive, high-quality pump can lead to significant savings over time when it comes to reduced downtime and lower maintenance needs.

Environmental concerns are increasingly influential in the choice of pumping solutions, and many suppliers are now focusing on developing eco-friendly pumps that minimize energy consumption and waste. Suppliers actively engaged in sustainability practices may provide pumps that not only meet regulatory standards but also help companies reduce their carbon footprint. This is an attractive proposition for industries looking to improve their environmental impact while maintaining operational efficiency.

In summary, vertical spindle slurry pumps are crucial in various industries due to their ability to handle challenging materials effectively. Businesses need to consider factors such as supplier reputation, technological advancements, cost-efficiency, and sustainability when selecting a supplier. In an evolving industrial landscape, partnering with a reliable and innovative supplier can lead to improved operational efficiency and significant cost savings, ultimately enhancing a company’s competitive edge in the marketplace.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025