Jul . 30, 2024 15:42 Back to list

Top Manufacturers of High-Quality Vertical Sump Pumps for Efficient Water Management Solutions

High-Quality Vertical Sump Pump Factories An Overview

Vertical sump pumps are essential components in various industrial applications, designed specifically to handle liquids with various solids and slurries. These pumps are particularly effective in environments with limited space, making them invaluable in mining, wastewater management, and construction industries. However, the effectiveness of these pumps significantly depends on the manufacturing standards employed by their factories. High-quality vertical sump pump factories ensure that the pumps produced meet rigorous performance and durability standards, essential for maintaining operational efficiency and safety.

The Importance of Quality in Manufacturing

Quality in the manufacturing of vertical sump pumps cannot be overstated. Poorly made pumps can lead to operational failures, increased maintenance costs, and even operational shutdowns. High-quality factories focus on using superior materials, advanced engineering techniques, and rigorous testing protocols to manufacture pumps that perform reliably under demanding conditions.

One of the critical aspects of quality manufacturing is the selection of materials. High-quality vertical sump pumps are typically crafted from corrosion-resistant materials that can withstand harsh environments. Factories often utilize stainless steel, cast iron, and specialized polymers that enhance both durability and performance. The choice of material not only impacts the pump's lifespan but also its efficiency in transporting liquids with varying viscosity and solid content.

Innovation and Technology in Pump Design

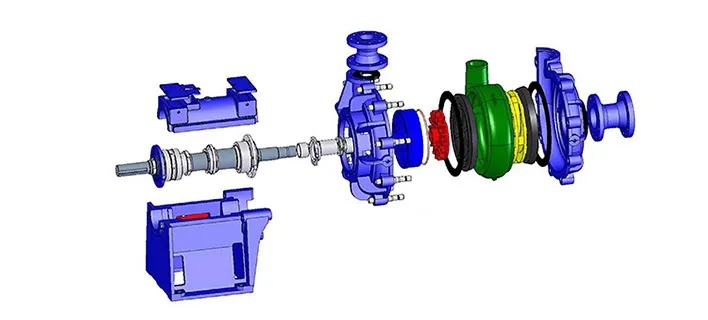

Leading vertical sump pump factories invest heavily in research and development to innovate their designs and integrate the latest technologies. Advanced manufacturing processes such as computer numerical control (CNC) machining, 3D printing, and computer-aided design (CAD) enable manufacturers to produce pumps with precise tolerances and complex geometries. These technological advancements result in pumps that are not only more efficient but also easier to maintain and service.

high quality vertical sump pump factories

Moreover, high-quality manufacturers focus on enhancing the hydraulic performance of their vertical sump pumps. This involves optimizing the impeller design, casing shape, and wear components to improve flow rates and reduce energy consumption. As industries increasingly seek ways to reduce their environmental footprint, energy-efficient pumps have become a priority, reinforcing the importance of innovation in pump factories.

Testing and Quality Assurance

An integral part of the manufacturing process in high-quality vertical sump pump factories is the testing and quality assurance phase. Every pump produced should undergo a series of rigorous tests to ensure that it meets industry standards and client specifications. These tests can include performance tests, pressure tests, and endurance tests to simulate real-life operating conditions.

Additionally, many reputable factories adhere to international quality standards such as ISO 9001, which outlines the criteria for quality management systems. Compliance with these standards ensures that the manufacturing processes are consistently monitored and improved, leading to a reliable product that meets customer expectations.

Conclusion

In conclusion, high-quality vertical sump pump factories play a crucial role in the supply chain of various industries that rely on efficient liquid handling solutions. By focusing on superior materials, innovative designs, and rigorous testing protocols, these factories produce pumps that not only perform effectively but also ensure long-term durability and reliability. As demands for industrial efficiency and environmental sustainability continue to rise, the importance of investing in high-quality vertical sump pump manufacturing will only grow. Companies seeking to optimize their operations should prioritize sourcing their pumps from established factories renowned for their commitment to quality and innovation.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025