Nov . 21, 2024 05:21 Back to list

suction dredge pump factory

Exploring the World of Suction Dredge Pumps A Look into the Factory

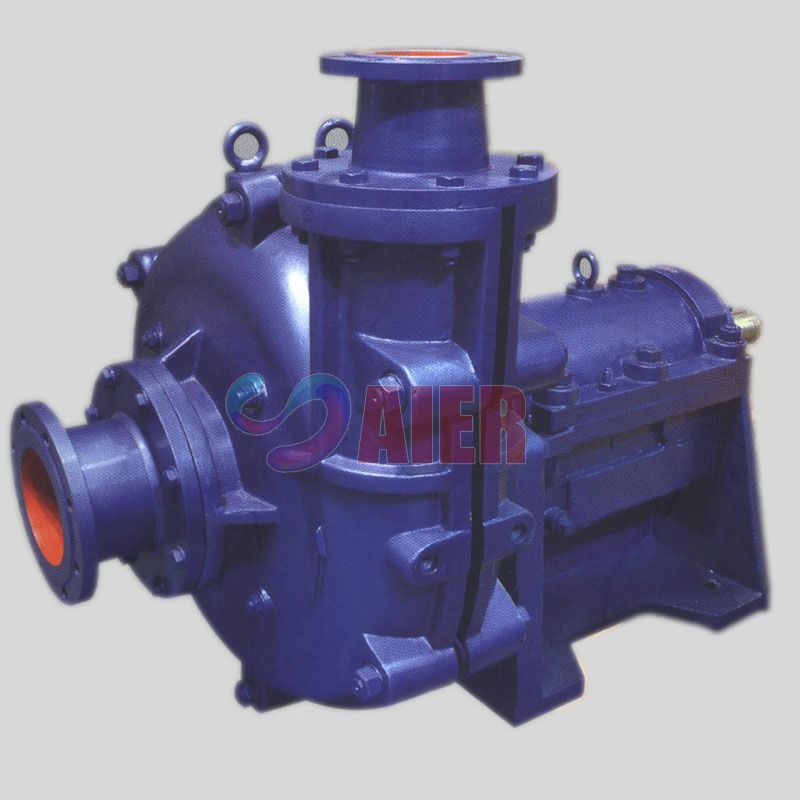

In the realm of industrial machinery, few components are as crucial in dredging and excavation activities as suction dredge pumps. These powerful devices play a vital role in the removal of sediment and debris from various water bodies, and understanding their manufacturing process at the factory level can provide insight into their significance in today’s construction and environmental management sectors.

What is a Suction Dredge Pump?

A suction dredge pump is designed to efficiently transport water along with sediment, sand, and other materials from underwater locations. Utilizing the principle of suction, these pumps create a low-pressure area that allows for the extraction of materials, making them essential tools in not just dredging, but also for maintaining waterways, beaches, and even mining operations. Their versatility can be attributed to a variety of sizes and configurations tailored to meet specific project requirements.

The Manufacturing Process of Suction Dredge Pumps

The journey of a suction dredge pump begins in the factory, where high-quality raw materials are sourced. Steel, often galvanized or stainless, is the primary material used for the casing and components due to its strength and resistance to corrosion. Rubber and polymer materials are frequently employed in components like impellers and hoses, ensuring durability and flexibility under varying conditions.

1. Design and Engineering Before any pump parts are produced, comprehensive design and engineering work is initiated. Engineers use advanced modeling software to create detailed specifications, ensuring that the pump will perform optimally under expected working conditions. Hydraulic analysis is essential to determine the most effective configurations for suction and discharge rates.

2. Manufacturing Parts Once designs are finalized, manufacturing begins. Parts are fabricated using techniques such as casting, forging, and machining. Each component—be it the impeller, suction inlet, or discharge outlet—is produced with precision to ensure optimal performance. Quality control checks are integral throughout this phase to assure adherence to industry standards.

suction dredge pump factory

3. Assembly Line After individual components are manufactured, they are transported to the assembly line. Skilled technicians assemble the pumps, meticulously fitting together parts to create a fully functional unit. This step requires a detailed understanding of the pump’s design and operational mechanics, as any misalignment can lead to inefficiencies or failure in the field.

4. Testing Phase Before any suction dredge pump leaves the factory, it undergoes rigorous testing. Manufacturers simulate working conditions to evaluate performance metrics, including suction capacity, discharge pressure, and operational efficiency. These tests help identify any flaws in design or assembly, allowing for necessary adjustments before delivery.

5. Final Inspection and Packaging Following successful testing, each pump is subject to a final inspection. Quality assurance teams ensure that every unit meets the required specifications and standards. Once cleared, the pumps are packaged securely for shipping to various markets, ranging from construction companies to municipal service providers.

Environmental Considerations

As industries across the globe increasingly prioritize sustainability, the production of suction dredge pumps is also evolving. Factories are adopting eco-friendly practices by minimizing waste, recycling materials wherever possible, and utilizing energy-efficient production processes. By embracing these changes, manufacturers are contributing to a more sustainable future without compromising the quality and efficacy of their products.

Conclusion

The factory process behind suction dredge pumps is a remarkable blend of engineering, skilled craftsmanship, and technological innovation. Understanding this intricate production journey highlights the pumps’ crucial role in various industrial applications, particularly in environmental management and construction. As technology advances, we anticipate further enhancements in pump design and efficiency, ensuring that these essential tools continue to contribute to effective dredging operations while meeting the demands of a changing world.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025