Sep . 14, 2025 08:00 Back to list

Submersible Well Pump Manufacturer | High-Efficiency & Durable Pumps

The Indispensable Role of a Modern Submersible Pump Manufacturer

In the complex landscape of industrial fluid management, the efficiency, reliability, and longevity of pumping systems are paramount. Submersible pumps, designed to operate fully immersed in the fluid they are pumping, offer distinct advantages over traditional surface pumps, particularly in applications requiring high lift, consistent flow, and robust performance in challenging environments. As a leading submersible well pump manufacturer, our commitment extends beyond mere production to engineering solutions that redefine industry standards for performance and durability.

From municipal water supply to intricate petrochemical operations, the demand for technologically advanced and highly reliable submersible pumping solutions continues to grow. This article delves into the critical aspects of modern submersible pump manufacturing, covering industry trends, technical excellence, and the comprehensive support systems that define a world-class supplier.

Navigating Industry Trends and Technological Advancements

The submersible pump industry is continually evolving, driven by global megatrends such as urbanization, industrial growth, and increasing environmental regulations. Key trends include the integration of IoT for predictive maintenance, advancements in material science for enhanced corrosion resistance, and a pervasive push towards energy efficiency. Modern submersible water pump manufacturers are focusing on intelligent pump systems that incorporate variable frequency drives (VFDs) and smart sensors to optimize energy consumption and provide real-time operational data.

- Energy Efficiency: Development of hydraulic designs and motor technologies that significantly reduce power consumption, aligning with global sustainability goals.

- Smart Integration: Incorporation of remote monitoring, diagnostic capabilities, and automation for proactive maintenance and operational optimization.

- Advanced Materials: Use of duplex stainless steels, ceramics, and specialized coatings to extend service life in highly abrasive or corrosive media.

- Modularity and Customization: Design flexibility to cater to diverse application requirements, from standard water pumping to specialized chemical transfer.

The Rigorous Manufacturing Process of a Submersible Pump

The production of a high-performance submersible pump is a meticulously controlled multi-stage process, ensuring precision, durability, and reliability. As a dedicated submersible well pump manufacturer, our process adheres to stringent international standards like ISO 9001 and ANSI, covering every step from raw material selection to final testing.

Manufacturing Process Flow:

- Material Selection & Sourcing: High-grade materials such as cast iron, stainless steel (SS304, SS316, Duplex SS), and wear-resistant alloys are selected based on application requirements. For abrasive media, chrome alloy steels or rubber linings are used.

- Casting & Forging: Impeller, casing, and motor housing components undergo precision casting or forging processes. This ensures optimal structural integrity and material density, critical for high-pressure applications.

- CNC Machining: Advanced Computer Numerical Control (CNC) machining centers are employed to achieve micron-level tolerances for critical components like shafts, impellers, and diffusers. This precision is vital for minimizing vibration, maximizing hydraulic efficiency, and extending service life.

- Motor Winding & Assembly: High-efficiency motors are wound with precision, insulated, and encapsulated to protect against water ingress. Quality checks ensure optimal electrical parameters and thermal management.

- Shaft & Seal Assembly: The pump shaft, often made from hardened stainless steel, is meticulously aligned with mechanical seals (e.g., silicon carbide, tungsten carbide) to prevent leakage and ensure reliable operation under varying pressures.

- Hydraulic Assembly: Impellers, diffusers, and volutes are assembled to create the hydraulic end, ensuring precise clearances and optimal flow paths. This is where energy-saving designs are realized.

- Integrated Assembly: All sub-assemblies are integrated, and wiring connections are sealed for waterproof integrity.

- Performance Testing: Each pump undergoes rigorous performance testing in a dedicated facility. This includes head-capacity curves, efficiency measurements, power consumption, vibration analysis, and watertight integrity tests (e.g., hydrostatic pressure tests). Test data is meticulously recorded and certified. Our pumps typically achieve efficiencies upwards of 80-85% under optimal conditions, a testament to our design and manufacturing prowess.

- Surface Treatment & Finishing: Protective coatings, paints, or specialized treatments are applied to enhance corrosion resistance and aesthetic appeal.

- Final Quality Control & Packaging: A final inspection ensures all specifications are met before secure packaging for shipment.

The typical service life for our submersible pumps, when properly maintained, ranges from 7 to 15 years, significantly reducing total cost of ownership for our clients.

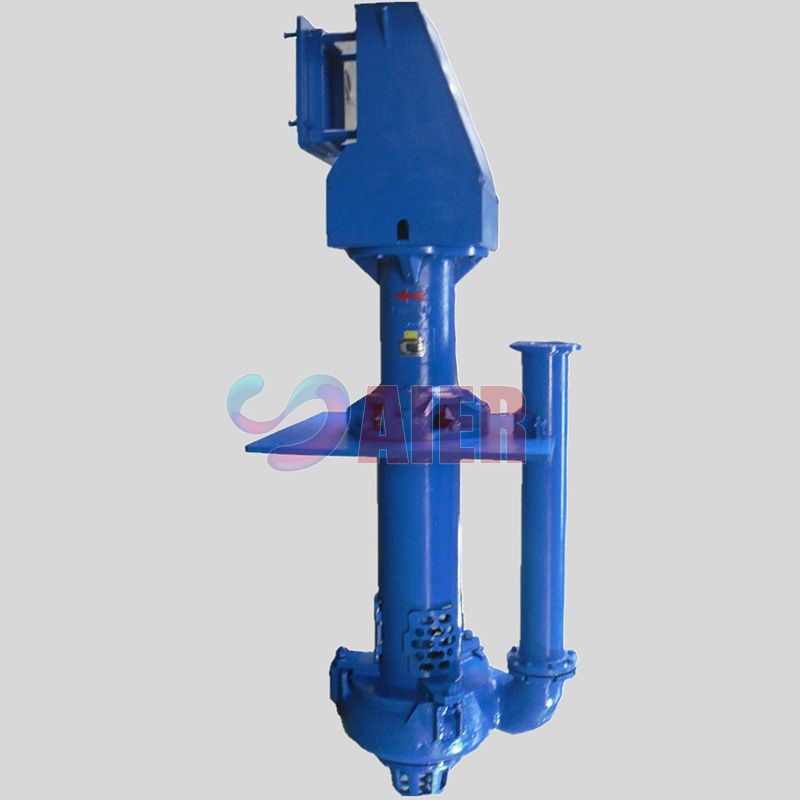

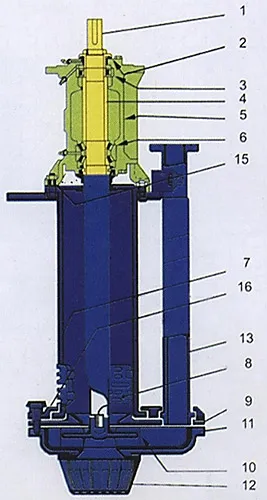

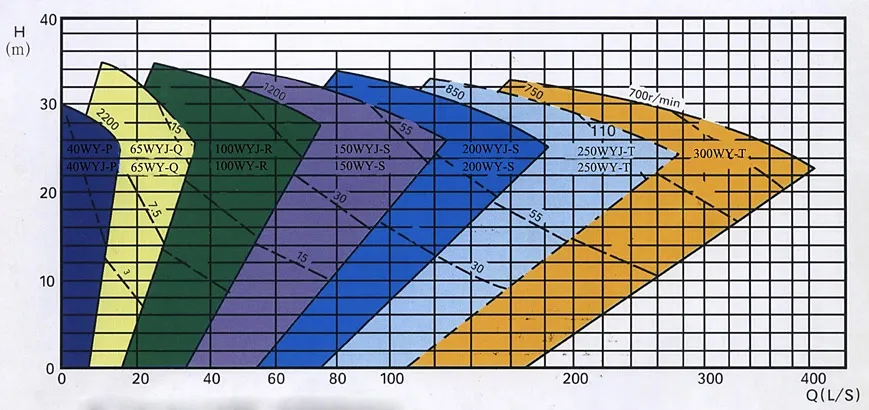

Technical Specifications: Focusing on the WY Sump Pump

Our WY Sump Pump series exemplifies robust design and superior performance, specifically engineered for demanding wastewater and industrial effluent applications. This series combines high-efficiency hydraulics with durable construction, making it an ideal choice for challenging conditions.

WY Sump Pump Key Specifications

| Parameter | Typical Range / Value | Description |

|---|---|---|

| Flow Rate (Q) | Up to 5000 m³/h (22000 GPM) | High capacity for rapid dewatering and transfer. |

| Head (H) | Up to 60 meters (200 ft) | Suitable for various lift requirements. |

| Motor Power | 5.5 kW - 250 kW (7.5 HP - 335 HP) | Robust motors for continuous operation. |

| Solid Passage | Up to 150 mm | Excellent clog resistance for sewage and slurries. |

| Materials of Construction | Cast Iron, SS304, SS316, Duplex SS, High-Chrome Alloy | Options for various corrosive and abrasive fluids. |

| Impeller Type | Single-vane, Multi-vane, Vortex, Chopper | Optimized for different fluid compositions. |

| Protection Class | IP68 | Full protection against dust and continuous immersion in water. |

| Insulation Class | F or H | High thermal resistance for motor longevity. |

Demonstrated Advantages:

- Energy Saving: Advanced hydraulic designs minimize energy consumption, leading to lower operational costs over the pump's lifecycle. Typical energy savings can be up to 15-20% compared to older models.

- Corrosion Resistance: Utilizing materials like SS316 and Duplex SS provides superior resistance to aggressive chemicals and seawater, significantly extending pump life in harsh environments.

- Wear Resistance: Hardened impellers and casings, often made from high-chrome alloys, withstand abrasive solids, making them ideal for slurry and sludge applications.

- Reliability: Double mechanical seals, thermal protection for motors, and robust bearing designs ensure continuous and trouble-free operation, minimizing downtime.

Diverse Application Scenarios and Target Industries

The versatility of our submersible pumps allows them to serve a broad spectrum of industries, providing critical solutions for fluid handling in diverse and demanding applications. Our expertise as a centrifugal submersible pump manufacturer extends to:

- Water Supply & Drainage: Municipal wastewater treatment plants, flood control, dewatering in construction sites, and irrigation systems.

- Petrochemical Industry: Handling crude oil, refined products, and various chemicals where explosion-proof motors and corrosion-resistant materials are essential.

- Metallurgy & Mining: Pumping abrasive slurries, mine dewatering, and tailings management, often requiring high-chrome alloy components and robust designs.

- Power Generation: Cooling water circulation, ash handling, and effluent disposal in thermal and nuclear power plants.

- Chemical Processing: Transfer of aggressive chemicals, requiring specialized materials like Duplex SS or Hastelloy.

- Food & Beverage: Sanitary applications for water and liquid food products, where hygiene and non-contaminating materials are critical.

Customer Feedback: "Our municipal wastewater treatment plant faced constant clogging issues with our previous pumps. Since implementing the WY Sump Pump series, we've seen a 90% reduction in maintenance calls related to blockages, significantly improving our operational efficiency and reducing costs." - Municipal Operations Manager, North America.

Technical Advantages Setting Us Apart

Our advantage as an electrical submersible pump manufacturer stems from a holistic approach to engineering, combining innovative design with robust construction. We focus on key areas that directly impact pump performance and lifespan:

- Motor Design and Efficiency: Our pumps feature IE3/IE4 compliant motors, designed for high efficiency and lower running temperatures. Integrated thermal protection and moisture sensors ensure motor longevity and prevent costly failures.

- Advanced Sealing Technology: Dual mechanical seals (silicon carbide to silicon carbide or tungsten carbide) in a separate oil chamber provide superior protection against fluid ingress, significantly extending seal life and preventing premature motor failure.

- Hydraulic Performance: Computational Fluid Dynamics (CFD) are extensively used to optimize impeller and volute designs, resulting in higher hydraulic efficiency, lower energy consumption, and reduced cavitation. This expertise ensures that our pumps, including those for sewage, are leaders as a submersible sewage pump manufacturer.

- Material Engineering: Beyond standard materials, we employ specialized alloys and coatings tailored to the specific corrosivity and abrasiveness of the pumped medium, enhancing the pump's resilience and operational life.

- Vibration and Noise Reduction: Precision balancing of rotating parts and robust bearing systems minimize vibration and noise, contributing to a longer mechanical seal and bearing life, and quieter operation.

Vendor Comparison: Choosing the Right Partner

When selecting a manufacturer of submersible pumps, it’s crucial to look beyond the initial purchase price. A reliable partner offers a combination of cutting-edge technology, robust quality assurance, comprehensive support, and proven track record. Here's a comparative overview of what distinguishes a top-tier manufacturer:

Key Differentiators in Submersible Pump Manufacturing

| Feature | Leading Manufacturer (Our Approach) | Standard Manufacturer |

|---|---|---|

| R&D and Innovation | Continuous investment in CFD, FEA, and advanced material science; development of smart pump solutions. | Relies on established designs; limited innovation; slower adoption of new technologies. |

| Quality Control | ISO/ANSI certified processes, 100% performance testing, material traceability, third-party inspections. | Basic QC, spot checks, less transparent testing, potential material inconsistencies. |

| Material & Components | High-grade raw materials (e.g., Duplex SS, SIC/TC seals), genuine OEM submersible pump part manufacturer components. | Cost-optimized materials, generic seals, potentially lower-grade imported parts. |

| Customization | Extensive engineering capabilities for bespoke solutions, tailored hydraulic and material selections. | Limited customization, primarily standard models with minor modifications. |

| After-Sales Support | Global service network, readily available submersible pump spares manufacturer parts, prompt technical assistance, maintenance contracts. | Delayed spare parts, limited technical support, potential language barriers (e.g. some china submersible pump manufacturer). |

| Warranty & Longevity | Extended warranties, proven long service life (7-15+ years), low total cost of ownership. | Basic warranty, shorter expected lifespan (3-5 years), higher long-term operational costs. |

Customized Solutions for Unique Challenges

Every industrial application presents its own set of unique challenges. Recognizing this, we excel in providing highly customized submersible pump solutions. Our engineering team collaborates closely with clients to understand specific fluid characteristics (viscosity, abrasiveness, corrosivity), operational parameters (head, flow, temperature), and site constraints. This allows us to tailor every aspect, from the selection of specific submersible pump part manufacturer components like impellers and seals to motor design and control systems.

For instance, for highly viscous slurries, we can design impellers with larger passages and specific blade geometries to prevent clogging. In corrosive chemical transfer, we might recommend exotic alloys or specialized coatings. Our capabilities extend to designing bespoke control panels, variable speed drives, and remote monitoring systems that integrate seamlessly with existing plant infrastructure. This consultative approach ensures that each pump is not just a product, but a precisely engineered solution.

Application Case Studies: Proving Our Mettle

Case Study 1: High-Abrasive Slurry in Mining Operations

A major copper mine in South America was struggling with rapid wear and frequent breakdowns of their existing dewatering pumps due to highly abrasive mine tailings. We provided a customized WY Sump Pump solution featuring a high-chrome alloy impeller, a robust agitator, and a heavy-duty shaft made by a reputable submersible pump shaft manufacturer. The pump’s design included an oversized bearing housing to cope with increased radial loads. After implementation, the client reported an average increase in mean time between failures (MTBF) by over 150% and a 30% reduction in annual maintenance costs. This direct impact on operational continuity underscored the value of our engineered solutions.

Case Study 2: Energy-Efficient Wastewater Treatment for a Chemical Plant

A large chemical manufacturing facility required an upgrade to their wastewater transfer system, with a primary focus on reducing energy consumption and handling corrosive effluents. We deployed our specialized WY Sump Pump units constructed with Duplex Stainless Steel and integrated them with variable frequency drives. The optimized hydraulic design, coupled with precise motor control, resulted in a verified 22% reduction in energy consumption compared to their previous pumps. Furthermore, the enhanced corrosion resistance drastically extended the operational life of the pumps in the aggressive chemical environment, leading to significant cost savings in parts and labor.

Commitment to Quality, Authoritativeness, and Trustworthiness

Our foundation as a leading submersible well pump manufacturer is built on an unwavering commitment to quality, backed by verifiable certifications and a robust service ethos. We are proud to hold ISO 9001:2015 certification, ensuring that our manufacturing processes consistently meet international quality management standards. Our products also adhere to specific industry standards such as ANSI/HI (Hydraulic Institute) and CE directives for European markets.

- Certifications: ISO 9001:2015 for Quality Management, CE for European conformity, ATEX for hazardous environments (where applicable).

- Partner Clients: We serve a global clientele including major players in mining, petrochemicals, water utilities, and construction, with years of successful partnerships and repeat business.

- Years of Service: With decades of experience in the pump manufacturing industry, our legacy is built on continuous innovation and customer satisfaction.

- Test Data & Analysis: Every pump undergoes comprehensive factory acceptance tests (FAT), with detailed performance curves and test reports provided to clients. Our data-driven approach instills confidence in product performance.

Trustworthiness & Comprehensive Support

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a custom submersible pump?

A: Standard models typically have a lead time of 4-6 weeks. Custom-engineered solutions may range from 8-12 weeks depending on complexity and material availability. Expedited options are available upon request. -

Q: What is your warranty policy?

A: We offer a standard 12-month warranty from the date of commissioning or 18 months from the date of shipment, whichever comes first, against manufacturing defects. Extended warranty options are available. -

Q: Do you provide on-site installation and commissioning support?

A: Yes, we offer comprehensive on-site support services, including installation supervision, commissioning, and operational training, provided by our experienced field engineers. -

Q: How do I order spare parts for my pump?

A: Spare parts can be ordered directly through our customer service department. Please provide your pump's serial number for accurate and prompt fulfillment. We maintain a comprehensive inventory of genuine submersible pump spares manufacturer components.

Lead Time & Fulfillment

Our streamlined production and logistics ensure efficient order fulfillment. We leverage global supply chain networks to source materials and components, allowing for competitive lead times. For critical projects, we can often expedite manufacturing and delivery schedules to meet urgent requirements, provided sufficient notice.

Warranty Commitments

Our commitment to quality is reflected in our robust warranty program. Beyond the standard warranty, clients can opt for tailored service agreements that include preventative maintenance, extended coverage, and guaranteed response times, ensuring peace of mind throughout the pump's operational life.

Customer Support & After-Sales Service

Our dedicated customer support team is available 24/7 for technical inquiries, troubleshooting, and spare parts assistance. We provide comprehensive after-sales service, including routine maintenance, repairs, and performance optimization, to ensure the sustained reliability and efficiency of your submersible pumping systems.

Conclusion

The selection of a submersible well pump manufacturer is a strategic decision that impacts operational efficiency, long-term costs, and environmental compliance. Our unwavering commitment to engineering excellence, advanced manufacturing processes, and comprehensive customer support positions us as a trusted partner for demanding industrial applications. By prioritizing innovation, quality, and tailored solutions, we deliver submersible pumps that not only meet but exceed the evolving needs of the global market.

References

- Hydraulic Institute. (2020). ANSI/HI 9.6.3 Rotodynamic (Centrifugal and Vertical) Pump Guideline for Vibration Measurements and Allowable Values.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems – Requirements.

- European Commission. (2014). Directive 2014/34/EU on equipment and protective systems intended for use in potentially explosive atmospheres (ATEX).

- P. G. S. (2018). Energy Efficiency in Pumping Systems. Elsevier.

- R. P. (2015). Pump Handbook (5th ed.). McGraw-Hill Education.

-

Essential Guide to FGD Pump Supplies – Efficiency and Sustainability for Industrial Emission Controls

NewsNov.24,2025

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025