Nov . 12, 2025 01:35 Back to list

Submersible Well Pump Manufacturer - ISO, Efficient, OEM

Submersible Well Pump Manufacturer is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of pumps, valves, compressors, and similar machinery. This article explores how Aier Machinery Hebei Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Submersible Well Pump Manufacturer Overview

- Benefits & Use Cases of Submersible Well Pump Manufacturer in Manufacturing of pumps, valves, compressors, and similar machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Submersible Well Pump Manufacturer from Aier Machinery Hebei Co., Ltd

Submersible Well Pump Manufacturer Overview

For B2B buyers in the general equipment manufacturing industry, selecting the right submersible well pump manufacturer is a strategic decision that affects uptime, operating expense, and water security. A submersible well pump is an integrated hydraulic and motor assembly installed below the waterline to deliver groundwater or process water with high reliability. Typical designs feature multi-stage centrifugal hydraulics, corrosion-resistant metallurgy (SS304/316 or duplex), robust shafts, and double mechanical seals. Leading manufacturers also offer electrical submersible pump options with VFD compatibility, sand-handling designs, and NEMA/ISO-compliant testing. As a china submersible pump manufacturer and full-line manufacturer of submersible pump solutions, Aier Machinery Hebei Co., Ltd supports OEM and end-user needs across agriculture, mining, industrial utilities, and municipal supply.

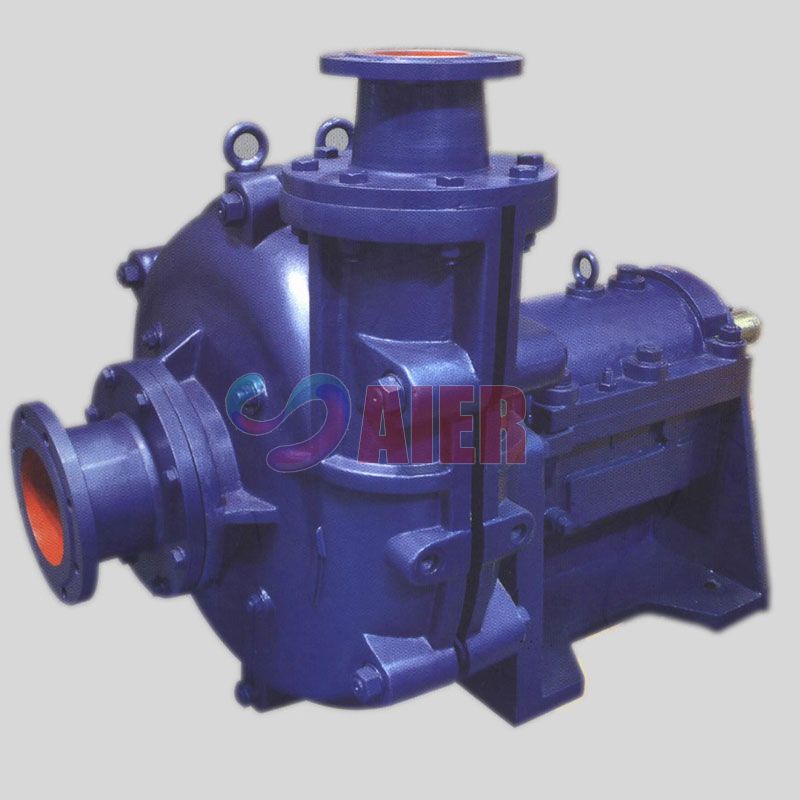

Aier’s portfolio spans clean-water and abrasive-duty applications, complementing well pumps with specialty models like the WZ high-efficiency slurry pump for harsh environments. This manufacturing depth matters to procurement leaders who value one supplier for pumps, spares, and engineered upgrades—whether you’re sourcing from a submersible water pump manufacturer, a submersible sewage pump manufacturer, or a centrifugal submersible pump manufacturer. With in-house capabilities as a submersible pump shaft manufacturer and submersible pump part manufacturer, Aier ensures dimensional accuracy, shorter lead times, and dependable interchangeability over the pump lifecycle.

Benefits & Use Cases of Submersible Well Pump Manufacturer in Manufacturing of pumps, valves, compressors, and similar machinery

In manufacturing environments, submersible well pumps supply process water, feed boiler makeup, support cooling systems, and handle dewatering around test bays. For OEMs and integrators in pumps, valves, and compressors, the right partner improves fluid-system efficiency, simplifies supply chains, and reduces warranty exposure. Aier Machinery Hebei Co., Ltd delivers application-specific hydraulics, material options, and motor selections to match head, flow, and fluid characteristics—ideal when you need an electrical submersible pump manufacturer that understands VFD-driven duty cycles, NPSH constraints, and solids tolerance for mixed-use water.

- Applications: industrial water supply, hydrostatic testing lines, cooling loops, groundwater control, and utility backup systems.

- Advantages: deep-set reliability, high efficiency stages, abrasion-resistant options, optimized shafts, and modular spares for rapid servicing.

- Support: as a submersible pump spares manufacturer, Aier provides matched impellers, diffusers, seals, and shafts to sustain performance across maintenance cycles.

Whether you’re qualifying a submersible sewage pump manufacturer for dirty water or a clean-water manufacturer of submersible pump assemblies for deep wells, Aier’s engineering and testing discipline helps deliver stable performance curves, reduced vibration, and extended MTBF—key metrics for B2B decision makers looking to consolidate vendors without compromising throughput.

Cost, Maintenance & User Experience

Total cost of ownership for submersible well pumps is driven by energy use, wear-life of hydraulic components, seal reliability, and service access. Aier designs for efficiency and durability—precision-balanced impellers, robust shafts, quality bearings, and double mechanical seals—helping reduce unplanned downtime and energy cost. For many facilities, improved hydraulic efficiency can deliver noticeable energy savings versus legacy units, while standardized spares and modular stages cut maintenance time and inventory exposure.

- Durability: corrosion-resistant materials and optimized shaft stiffness minimize deflection and extend seal life.

- Serviceability: as a submersible pump spares and submersible pump shaft manufacturer, Aier ensures fast part identification and availability.

- ROI: higher uptime and lower kWh/m³, with positive feedback from industrial users who benchmarked performance against prior fleets.

Procurement teams also value the user experience: clear documentation, responsive technical support, and testing transparency. Aier supports factory acceptance testing and performance verification to ISO-oriented methods, giving B2B stakeholders confidence in the delivered duty point and long-term lifecycle results.

Sustainability & Market Trends in manufacturing

Across the pump industry, sustainability is reshaping specifications: higher-efficiency hydraulics, variable-speed operation, and longer service intervals to cut waste. Global directives—such as EU Ecodesign and U.S. efficiency initiatives—are pushing buyers toward best-in-class energy performance and measurably lower lifecycle emissions. As a forward-looking china submersible pump manufacturer, Aier Machinery Hebei Co., Ltd invests in advanced casting, precision machining, and optimized hydraulics to support these goals, while offering materials that extend wear life in challenging water chemistry.

Digitalization is another trend: sensor-ready designs and VFD compatibility enable smarter operations, smoother ramp profiles, and protection against dry-run or off-curve conditions. In parallel, Aier’s broader lineup—exemplified by the WZ high-efficiency slurry pump—shows how the company applies energy-efficient thinking beyond wells to abrasive-duty services. The outcome is practical sustainability: fewer changeouts, lower kWh per cubic meter, and reduced total environmental impact from a trusted electrical submersible pump manufacturer.

Conclusion on Submersible Well Pump Manufacturer from Aier Machinery Hebei Co., Ltd

Choosing a Submersible Well Pump Manufacturer is ultimately about lifecycle value: dependable hydraulics, energy efficiency, and assured parts availability. Aier Machinery Hebei Co., Ltd stands out as a comprehensive manufacturer of submersible pump solutions—with in-house capability as a submersible pump part manufacturer, submersible pump shaft manufacturer, and a reliable partner for both clean-water and slurry-facing demands. From submersible water pumps to sewage-ready designs, Aier delivers the performance B2B leaders expect.

- Elevate uptime and cut TCO with a proven submersible well and centrifugal submersible pump manufacturer.

- Reputation you can trust: engineering depth, consistent quality, and responsive support.

- Contact us: email: sales@aierpump.com - Visit our website: https://www.aierpumps.com

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025