Oct . 20, 2025 11:25 Back to list

Submersible Well Pump Manufacturer | ISO-Certified OEM

Choosing a Submersible Well Pump Manufacturer in 2025—What Slurry Pumps Taught Me

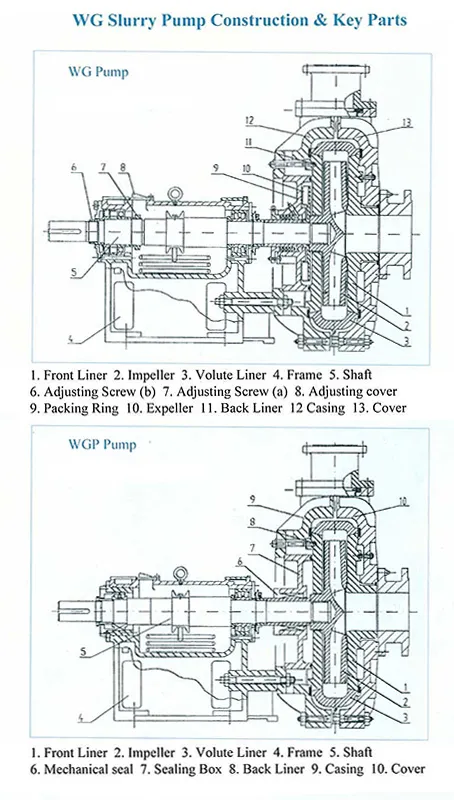

If you’re hunting for a submersible well pump manufacturer, here’s a slightly counterintuitive tip: look closely at how that company builds its heavy-duty slurry pumps. Why? The engineering discipline (materials, seals, balancing, verification tests) is even harsher there. Take the WG High Head Slurry Pump from China—it’s built for ash removal and liquid–solid mixtures in power, metallurgy, and coal. In fact, watching this model evolve has been a masterclass in durability and QA, which directly translates to reliable deep-well gear.

Industry trends I’m seeing

- Materials shift to duplex and high-chrome irons; elastomers tuned for abrasion.

- VFD-ready motors; sensor kits for vibration, temp, and leak detection.

- Efficiency testing per ISO 9906, with real-world curves published (or at least they should be).

- Sustainability: repairable wet-ends, recycled sand castings, longer service intervals.

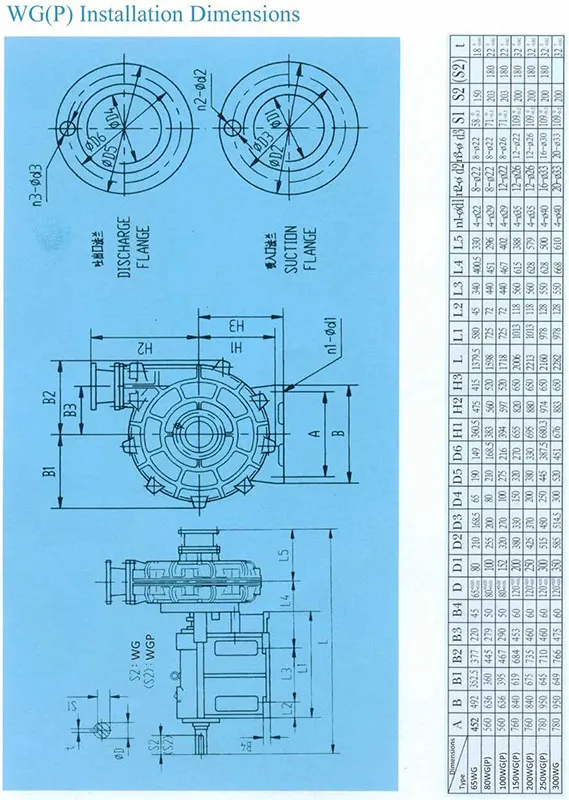

WG High Head Slurry Pump: quick specs (indicative)

| Flow range | ≈ 50–1200 m³/h (real-world use may vary) |

| Head | ≈ 40–120 m single; up to ≈ 300 m multi-stage |

| Solids handling | Up to ~45% by weight; max particle ≈ 8–65 mm |

| Materials | Hi-Cr iron (A05/A49), rubber-lined options |

| Seal options | Packing, expeller, or mechanical |

| Speed / Power | ≈ 400–1800 rpm; 30–560 kW |

| Temp | Max ≈ 110°C |

| Testing | ISO 9906 Grade 2B; hydrostatic test |

| Service life | Wet-end ≈ 6,000–12,000 h; bearings ≈ 30,000 h with clean lube |

How it’s built and tested (the telltale signs)

Materials come from certified foundries, cast via sand or lost-foam, heat-treated, and machined to tight tolerances. Impellers are dynamically balanced to ISO 1940 (G6.3 is common). Final assembly gets vibration checks (ISO 20816), hydrostatic pressure tests, and performance verification against ISO 9906. Honestly, when a submersible well pump manufacturer can show a similar test stack—plus UL 778 motor compliance and NSF/ANSI 61 for potable water—you’re in good hands.

Where it’s used (and what users say)

- Power plants: ash and FGD slurries—operators report fewer seal failures after switching to expeller seals.

- Metallurgy/mining: mill discharge with abrasive fines; many customers say chrome iron with rubber liners is a sweet spot.

- For wells: irrigation, municipal supply, geothermal. A capable submersible well pump manufacturer should offer sand-handling designs, stainless hydraulics, VFD-ready motors, and long drop cables.

Vendor comparison at a glance

| Vendor Type | Lead Time | Price Index | Certifications | Customization |

|---|---|---|---|---|

| China manufacturer (e.g., Aier) | ≈ 3–6 weeks | $$ | ISO 9001, CE; UL/NSF on request | High (materials, seals, stages) |

| EU premium brand | ≈ 6–12 weeks | $$$–$$$$ | ISO 5199, ATEX/IECEx options | Medium–High |

| Local distributor | Stock–2 weeks | $$$ | Varies | Low–Medium |

Customization to insist on: metallurgy (duplex/316 for wells; A05 for slurry), sealing (SIC/SIC/EPDM for sandy water), cable length, discharge size, and VFD tuning. A solid submersible well pump manufacturer will share drawings fast.

Field notes (two quick cases)

- Thermal power, fly ash: WG multi-stage train moved 18% solids at ≈ 210 m head; after impeller upgrade, energy use dropped ~9% and MTBR improved to 14 months.

- Agricultural borewell, 6-inch: sand ≈ 150 g/m³; stainless submersible pump with SIC/SIC seal lasted 14 months before overhaul—surprisingly good given the grit.

Bottom line: if a maker publishes ISO 9906 curves, shows material certs, and proves real test data, they’re not just marketing. That’s the kind of submersible well pump manufacturer you want on speed dial.

Authoritative citations

- ISO 9906: Rotodynamic pumps—Hydraulic performance acceptance tests

- ISO 5199: Technical specifications for centrifugal pumps—Class II

- ANSI/HI Pump Standards: Hydraulic Institute guidance on testing and installation

- UL 778 and NSF/ANSI 61: Motor-driven pumps and drinking water system components

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025