Sep . 01, 2025 01:20 Back to list

Submersible Well Pump Manufacturer - Efficient Water & Sewage Solutions

Navigating the Modern Landscape of Submersible Pump Manufacturing

The global industrial sector is increasingly reliant on efficient and robust fluid management systems. At the heart of many critical operations, from deep well water supply to aggressive slurry handling, lies the expertise of a specialized submersible well pump manufacturer. These manufacturers are pivotal in providing solutions that address the unique challenges of fluid transport in submerged conditions, ensuring reliability, longevity, and optimal performance.

Modern industry trends for submersible pumps are shaped by several factors, including the escalating demand for energy efficiency, stringent environmental regulations, and the need for durable materials capable of withstanding corrosive and abrasive media. The market for industrial pumps is projected to grow significantly, driven by infrastructure development, expanding industrialization, and increased investment in water and wastewater treatment facilities. This growth underscores the critical role of advanced engineering and manufacturing capabilities in producing pumps that not only meet but exceed operational expectations.

Technological advancements are continuously pushing the boundaries of what is possible in submersible pump design. Innovations include smart monitoring systems for predictive maintenance, advanced impeller designs for higher hydraulic efficiency, and the integration of variable frequency drives (VFDs) for optimized energy consumption. Furthermore, the development of specialized alloys and composite materials has significantly improved the resistance of pump components to chemical attack and abrasive wear, extending service life in demanding applications such as mining, petrochemicals, and heavy industrial processing. A reliable submersible water pump manufacturer must keep pace with these innovations to remain competitive and deliver value to their clients.

The Manufacturing Process: Precision Engineering by a Leading Submersible Pump Manufacturer

The creation of a high-performance submersible pump is a testament to meticulous engineering and advanced manufacturing techniques. As a comprehensive manufacturer of submersible pump solutions, the process involves several critical stages to ensure each unit meets stringent quality and performance standards.

Process Flow Overview:

- Design and Engineering: Utilizing CAD/CAM software for hydraulic design, mechanical structure, and material selection based on fluid properties and application requirements. Finite Element Analysis (FEA) is often employed to predict stress distribution and ensure structural integrity.

- Material Procurement and Preparation: Sourcing high-grade raw materials such as stainless steels (e.g., SS304, SS316, Duplex SS), cast iron, and specialized alloys for components like impellers, casings, and shafts. For abrasive applications, materials like high-chrome alloy iron are selected.

- Casting & Forging:

- Casting: Precision casting for pump casings, impellers, and other intricate components, ensuring dimensional accuracy and surface finish. Alloys are melted and poured into molds, followed by cooling and demolding.

- Forging: Forging of pump shafts and critical fasteners to enhance material strength, grain structure, and fatigue resistance, particularly crucial for a submersible pump shaft manufacturer.

- CNC Machining: High-precision CNC machining of all components to meet tight tolerances, ensuring optimal hydraulic performance and mechanical fit. This includes impellers, diffusers, motor housings, and sealing arrangements.

- Heat Treatment & Surface Finishing: Heat treatment processes to achieve desired material properties (e.g., hardness, toughness). Surface treatments like polishing, passivation, or ceramic coating may be applied for enhanced corrosion and abrasion resistance.

- Motor Winding & Assembly: Manufacturing or sourcing high-efficiency submersible motors. This includes stator winding, rotor assembly, and encapsulation to ensure waterproof integrity and thermal management.

- Final Assembly: Meticulous assembly of all pump components, including impellers, diffusers, shaft, motor, mechanical seals, and electrical connections, often in a clean environment to prevent contamination.

- Rigorous Testing: Each pump undergoes extensive performance testing in accordance with international standards such as ISO 9906 (for hydraulic performance) and ANSI/HI standards. This includes hydrostatic pressure tests, vibration analysis, motor electrical tests, and full-load run tests to verify head, flow, efficiency, and power consumption. A dedicated electrical submersible pump manufacturer places immense emphasis on these testing phases.

- Quality Control & Certification: Comprehensive quality inspections at every stage, culminating in final product certification. Many manufacturers adhere to ISO 9001 for quality management and ISO 14001 for environmental management.

- Packaging and Shipping: Secure packaging for safe transport, often with custom crating for large or specialized units.

Target industries for these robust pumps include petrochemical, metallurgy, mining, power generation, municipal water supply and drainage, and agriculture. The typical service life of a well-maintained submersible pump from a reputable submersible well pump manufacturer can exceed 10-15 years, largely due to superior material selection and precision manufacturing.

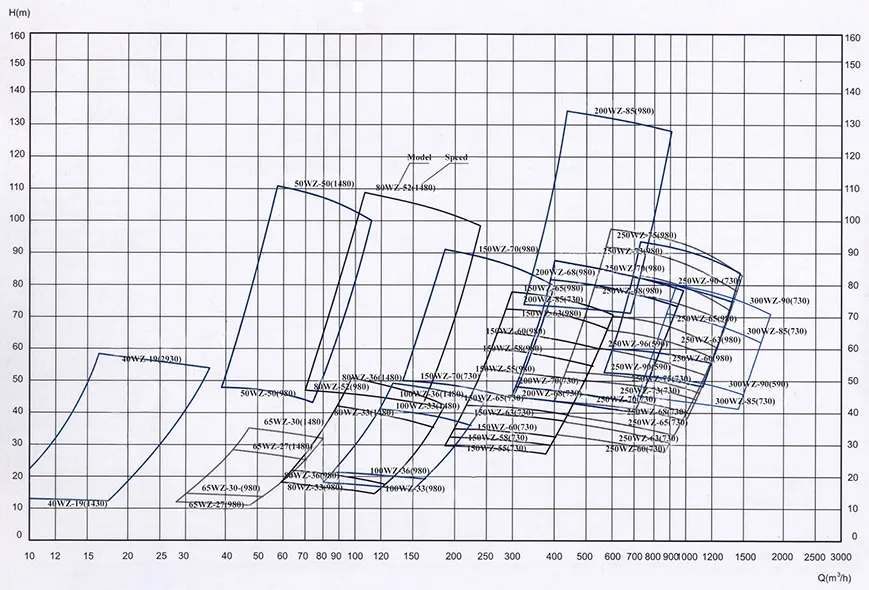

Technical Specifications and Parameters: WZ High Efficiency Slurry Pump

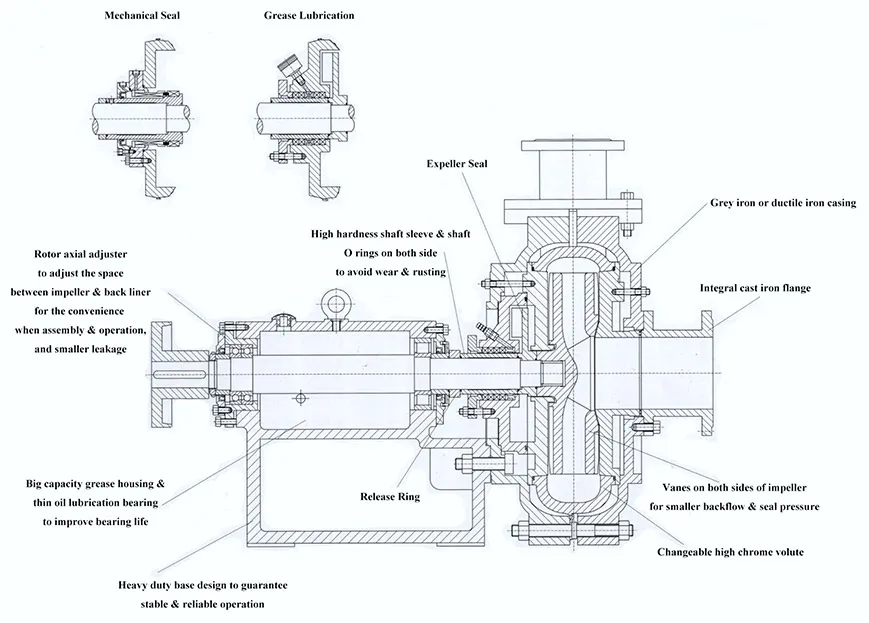

As a leading submersible well pump manufacturer specializing in demanding applications, our WZ High Efficiency Slurry Pump exemplifies advanced hydraulic design and material technology. This pump is engineered to handle abrasive and high-density slurries with exceptional efficiency and minimal wear.

WZ High Efficiency Slurry Pump Key Specifications:

These parameters reflect the engineering prowess expected from a top-tier submersible water pump manufacturer, demonstrating a commitment to performance and durability in the most challenging conditions.

Application Scenarios and Technical Advantages

The versatility of submersible pumps manufactured by an expert submersible well pump manufacturer makes them indispensable across a multitude of industrial and environmental applications. Their inherent design, being fully submerged, offers distinct advantages over surface-mounted pumps, particularly in terms of priming, noise reduction, and space efficiency.

Key Application Areas:

- Mining & Mineral Processing: Dewatering open-pit mines, tailings ponds, and handling mineral slurries. The WZ Slurry Pump excels here due to its robust construction and abrasion-resistant materials.

- Dredging & Sand Extraction: Efficiently moving sand, gravel, and sediment from riverbeds, lakes, and marine environments.

- Construction & Civil Engineering: Pumping muddy water, sludge, and bentonite from construction sites, tunnels, and foundations.

- Industrial Sump Pumping: Handling wastewater, coolants, and process fluids in industrial sumps and pits.

- Power Generation: Ash handling in power plants and dewatering applications.

- Wastewater Treatment: A submersible sewage pump manufacturer provides solutions for municipal and industrial wastewater collection and treatment facilities, handling raw sewage and activated sludge.

Technical Advantages:

- Energy Saving: Advanced hydraulic designs minimize internal friction and turbulence, leading to higher efficiency and reduced power consumption. Variable speed options further optimize energy usage based on demand.

- Corrosion and Abrasion Resistance: Strategic material selection (e.g., high-chrome alloys, polyurethane, rubber liners) ensures longevity in highly corrosive or abrasive media, reducing maintenance costs and downtime.

- Self-Priming Capability: Being submerged, these pumps are naturally self-priming, eliminating the need for external priming systems and simplifying installation.

- Reduced Noise and Vibration: The surrounding fluid acts as a natural sound dampener, resulting in quieter operation compared to surface-mounted pumps.

- Compact Footprint: Submersible pumps require less surface space, making them ideal for installations where space is a premium.

- Thermal Management: The motor is cooled by the pumped fluid, which helps dissipate heat efficiently, extending motor life.

Vendor Comparison and Customized Solutions

Selecting the right submersible well pump manufacturer is a critical decision that impacts operational efficiency, maintenance costs, and overall project success. While many suppliers offer submersible pumps, distinguishing factors lie in their engineering capabilities, material science expertise, and commitment to customized solutions.

Key Differentiators in Vendor Selection:

Customized Solutions:

A truly professional submersible well pump manufacturer recognizes that off-the-shelf solutions are rarely optimal for complex industrial challenges. Customization options extend beyond material selection to include:

- Impeller and Hydraulic Design: Tailoring impeller geometry (number of vanes, blade angles, eye diameter) to handle specific solid concentrations, particle sizes, and flow characteristics.

- Motor Configurations: Offering various voltage, frequency, and explosion-proof (ATEX) ratings, as well as integrated smart monitoring sensors.

- Sealing Arrangements: Customizing mechanical seal types (single, double, cartridge), material combinations, and external flush systems for media containing crystallizing or abrasive particles.

- Wear Parts Optimization: Providing specialized submersible pump part manufacturer components with enhanced wear resistance for critical areas like suction plates and diffusers.

- Mounting and Installation Accessories: Custom discharge connections, guide rail systems, and control panel integration.

Application Case Studies and Customer Experience

Real-world application validates the claims of any submersible well pump manufacturer. Our pumps have been deployed in diverse and challenging environments, consistently delivering superior performance and reliability.

Case Study 1: Iron Ore Mine Dewatering

Client: A major iron ore mining corporation in Australia.

Challenge: Excessive groundwater ingress into open-pit mine, carrying highly abrasive iron ore fines and requiring continuous dewatering.

Solution: Installation of several WZ High Efficiency Slurry Pumps, specifically configured with A05 high-chrome alloy impellers and wear plates. Pumps were equipped with smart monitoring systems for real-time performance and predictive maintenance.

Results: The pumps demonstrated exceptional wear life, exceeding the client's previous pump solutions by 150%. Energy consumption was reduced by 12% due to optimized hydraulic design and VFD integration. Downtime for pump maintenance decreased by 60%, significantly improving operational continuity. Customer feedback highlighted the robustness and efficiency as critical for their large-scale operations.

Case Study 2: Municipal Wastewater Treatment Plant

Client: A municipal authority managing a large urban wastewater treatment plant.

Challenge: Clogging issues and frequent maintenance due to high fiber content and solids in raw sewage, leading to increased operational costs.

Solution: Deployment of custom-designed WZ series pumps with vortex impellers and specialized non-clogging features. The pump casing was coated for enhanced corrosion resistance, and robust double mechanical seals were used.

Results: Clogging incidents were reduced by over 90%, drastically cutting down on manual intervention and associated labor costs. The pumps demonstrated consistent performance, contributing to uninterrupted operation of the treatment facility. This project further solidified our reputation as a reliable china submersible pump manufacturer with global reach.

Authoritative References and Certifications:

Our commitment to quality and performance is underpinned by adherence to international standards. We maintain ISO 9001 certification for quality management systems, ensuring consistent product quality from design to delivery. Our pumps are designed and tested to meet or exceed industry benchmarks such as ISO 9906 for hydraulic performance and relevant CE directives for safety. We partner with leading engineering firms and consultancies globally, solidifying our authoritative standing in the submersible pump market. Years of service, often spanning decades, with key industrial clients globally, attest to our proven track record.

Trustworthiness, Support, and Logistics

Building trust with our B2B clients is paramount. This extends beyond product quality to encompass transparent communication, reliable support, and clear commitments.

Frequently Asked Questions (FAQ):

- Q1: What is the typical lead time for a customized submersible pump?

- A1: Lead times vary based on customization complexity and component availability. Standard models typically ship within 4-6 weeks. Highly customized units may require 8-12 weeks, subject to engineering approval and material procurement. We provide a detailed project schedule upon order confirmation.

- Q2: What warranty is offered on your submersible pumps?

- A2: We offer a standard 12-month warranty from the date of commissioning or 18 months from the date of shipment, whichever comes first, covering defects in materials and workmanship. Extended warranty options are available upon request.

- Q3: How do you ensure the availability of submersible pump spares manufacturer parts?

- A3: We maintain a comprehensive inventory of critical spare parts for all active pump models. Our global logistics network ensures timely delivery of spares, minimizing downtime. We also offer recommended spare parts lists for planned maintenance.

- Q4: Can you provide installation and commissioning support?

- A4: Yes, our experienced technical team provides comprehensive remote and on-site support for installation, commissioning, and operational training. We ensure your team is fully equipped to operate and maintain the pumps efficiently.

Lead Time and Fulfillment:

Our manufacturing facilities operate with lean principles to optimize production cycles. We leverage advanced ERP systems to manage inventory and production, providing accurate lead time estimations. For urgent requirements, expedited manufacturing and shipping options can be arranged.

Warranty Commitments:

Our warranty terms are designed to provide peace of mind, reflecting our confidence in the durability and quality of our products. We stand by our pumps and are committed to resolving any manufacturing defects promptly and efficiently.

Customer Support:

Our dedicated customer support team is available 24/7 for technical assistance, troubleshooting, and spare parts inquiries. We offer remote diagnostics, detailed maintenance manuals, and comprehensive training programs to ensure optimal pump performance throughout its service life. Our global network of service partners further extends our reach, providing local support wherever our pumps are deployed.

Conclusion: Partnering with an Advanced Submersible Pump Manufacturer

The complexities of modern industrial fluid handling demand more than just a pump; they require a robust, efficient, and reliable solution backed by expert engineering and unwavering support. As a leading submersible well pump manufacturer, we pride ourselves on delivering cutting-edge technology, superior materials, and tailor-made solutions for the most demanding applications. Our commitment to innovation, quality, and customer satisfaction ensures that our pumps not only meet current operational needs but also provide long-term value and sustainability.

From initial design and meticulous manufacturing to comprehensive after-sales support, our integrated approach guarantees optimal performance and longevity. Partnering with a proven submersible pump part manufacturer means investing in a solution that will reduce operational costs, minimize downtime, and contribute significantly to your project's success.

References

- ISO 9906: Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3. International Organization for Standardization.

- ANSI/HI Standards 9.1-9.5: Pumps - General Guidelines for Pumps. Hydraulic Institute.

- Karassik, I. J., & Messina, J. P. (1989). Pump Handbook. McGraw-Hill.

- Slurry Handling and Pumping. Weir Minerals White Paper.

- World Water Forum Reports on Water Infrastructure Development.

-

Essential Guide to FGD Pump Supplies – Efficiency and Sustainability for Industrial Emission Controls

NewsNov.24,2025

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025