Nov . 07, 2025 11:55 Back to list

Submersible Well Pump Manufacturer | Efficient, Durable, OEM

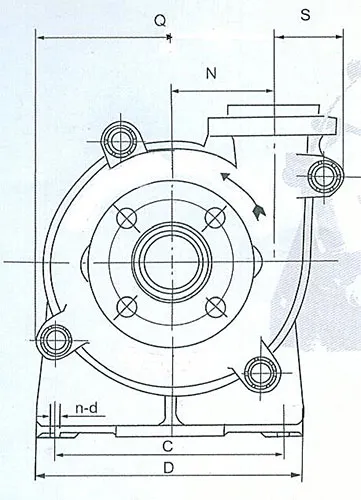

If you want to see what a real Submersible Well Pump Manufacturer looks like when they also build tough slurry equipment, spend an afternoon with the WL Series team in China. I did—well, virtually—and what stood out wasn’t just the metal, it was the discipline behind it. Their WL Light-duty Slurry Pump is a cantilevered, horizontal centrifugal unit aimed at low-density slurries in metallurgy, mining, coal prep, and building materials. Not flashy. Just solid.

Industry trend check

Two things are shaping the pump market: efficiency mandates and uptime economics. Actually, three—global lead times. Buyers want ISO-backed performance data, abrasion-resistant wet ends, and quick spares. WL fits the “reliable, serviceable, not-overengineered” sweet spot, which—many customers say—wins over spec sheets alone.

Product snapshot: WL Light-duty Slurry Pump

Origin: China. Configuration: horizontal, overhung (cantilevered). Seal options: gland packing and centrifugal seal. Materials: high-chrome iron for impeller/liner, elastomer options for corrosive fines. It’s built for low-density slurries; not a “brute-force” tailings beast—more like the dependable workhorse on the line.

| Spec (WL Series, typical) | Value (≈, real-world may vary) |

|---|---|

| Flow rate | up to ≈ 360 m³/h |

| Head | ≈ 10–45 m |

| Solids size | up to ≈ 8–12 mm |

| Materials | Hi-Chrome (A05/A49), optional rubber |

| Speed | ≈ 800–2200 rpm |

| Shaft seal | Gland packing / centrifugal |

| Max temp | ≈ 80°C |

How it’s built (short version)

Materials are poured as high-chrome iron, heat-treated, then CNC-machined. Impellers are dynamically balanced to ISO 1940 G6.3. Casing pressure test per ISO 9906 acceptance grades. Performance checked on a closed-loop test bed; vibration per ISO 10816. Elastomer parts get durometer checks. It sounds dry, but this is where service life—often 4,000–8,000 h on fines—comes from, assuming reasonable slurry density.

Where it fits

Metallurgical plant sumps, cyclone feed standby, coal fines transfer, sand and aggregate wash circuits, ceramic slip. If you’re pushing ultra-abrasive tailings at high head, pick a heavier class; otherwise WL is frankly a cost-savvy choice.

Why buyers choose it

- Serviceability: split-case, easy liner swaps.

- Seal flexibility: gland or centrifugal to match water availability.

- Parts ecosystem: around 8–12 week global delivery on wear sets (my notes show better during off-peak).

Customization

No mystery here: impeller diameter trims, metallurgy swaps (A05/A49), rubber lining, suction liners with extended lip, flanged or Victaulic connections, baseplate footprint matching legacy frames. Documentation: ISO 9001 quality pack, material certs (EN 10204 3.1 on request).

| Vendor type | Certs | Lead time | Typical advantage |

|---|---|---|---|

| AIER WL (China) | ISO 9001, CE (models) | ≈ 4–10 wks | Value, robust wear parts |

| Local fabricator | Varies | ≈ 2–6 wks | Fast service, limited range |

| Premium EU brand | ISO 9001/14001 | ≈ 10–20 wks | Peak efficiency, pricey |

Field notes

Case 1: Iron ore plant, Inner Mongolia—WL on classifier overflow, 180 m³/h at 18 m. Wear audit after 2,400 h showed ≈ 1.1 mm average liner loss; impeller trim held. Case 2: Sand wash in SE Asia—operators reported 30% less gland water after switching to centrifugal seal; maintenance crew said “easier to unbolt than the old unit.”

Testing, data, standards

Shop tests follow ISO 9906 acceptance grades for performance; vibration trending with ISO 10816 guidance; pressure testing at 1.5× rated working pressure. For corrosive slurries, lab coupons help pick between A05/A49. Frankly, the boring paperwork is what de-risks commissioning.

Selection tip: start with duty point ±10%, choose the largest efficiency island that still gives wear margin, then lock seals based on water availability. If your process shifts, WL’s impeller trims keep you out of the “too much recirculation” trap.

What customers tell me: “It’s not the fanciest, but it runs.” That, plus accessible pricing, is often all the ROI math you need.

If you need help mapping WL sizes to your duty, reach out to the team—this Submersible Well Pump Manufacturer also understands slurry, which is rarer than it should be, to be honest.

- ISO 9906:2012 – Rotodynamic pumps – Hydraulic performance acceptance tests

- ISO 10816-3:2009 – Mechanical vibration – Evaluation of machine vibration

- ISO 1940-1:2003 – Mechanical balance quality of rotating components

- EN 10204:2004 – Metallic products – Types of inspection documents

- ISO 9001:2015 – Quality management systems – Requirements

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025