Oct . 19, 2025 11:40 Back to list

Submersible Well Pump Manufacturer | Efficient, Durable OEM

Inside the workshop: notes from a submersible world and the hunt for a submersible well pump manufacturer

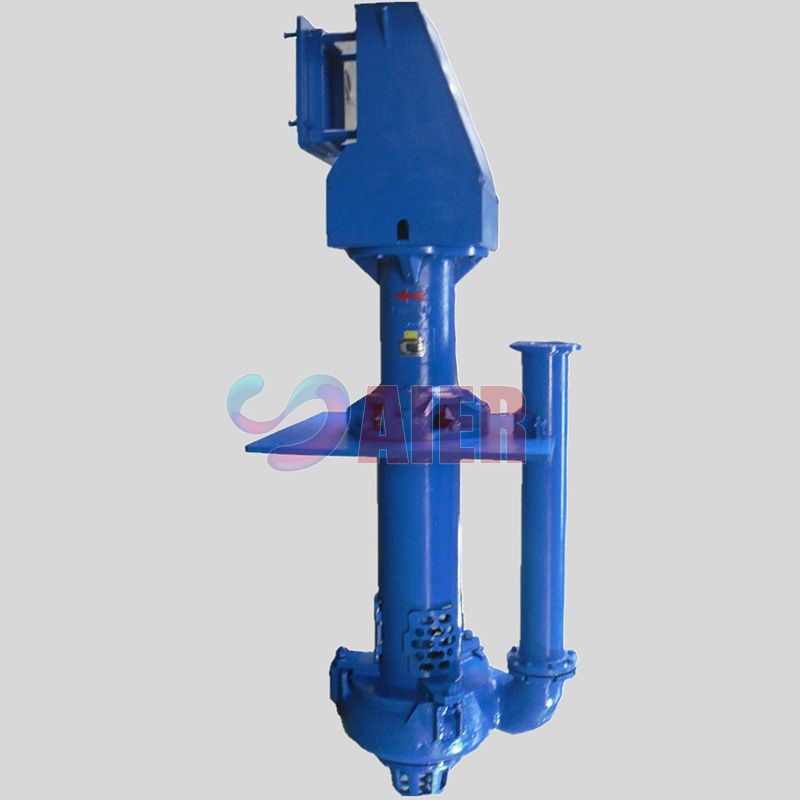

I’ve toured more than a few pump factories over the last decade, and—honestly—the line between “good enough” and “built to last” shows up fast in slurry service. The WY Sump Pump out of China keeps popping up in mines and quarries I visit. It’s a vertical centrifugal slurry unit designed to live submerged, push high-density, abrasive slurries, and—surprisingly—do it without seal water or mechanical seals. That’s a big maintenance win, especially when suction volume fluctuates. Many customers say that’s what sold them.

Industry trends I keep hearing about

- Shift to no-seal submersible/vertical designs to cut downtime and flush water costs.

- Harder wear materials (high-chrome irons, elastomer options) to stretch service life.

- Monitoring add-ons—simple vibration/temperature sensors tied to VFDs.

- More customization: sump depth, shaft length, and metallurgy matched to solids chemistry.

Product snapshot: WY Sump Pump (Origin: China)

WY & WYJ are vertical slurry pumps: submerged bowl, cantilever shaft, open or semi-open impeller choices, and a casing built to take a beating. It can keep moving slurry even when the sump runs low. In fact, that “no seal water” aspect is what operations teams mention first.

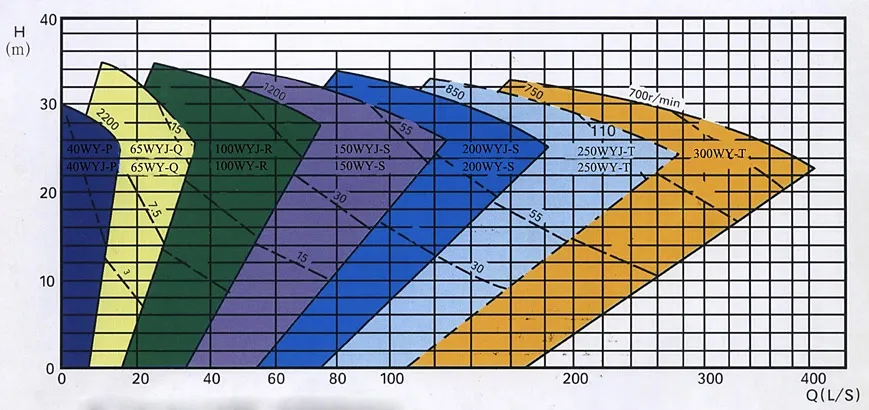

Indicative specifications (real-world use may vary)

| Parameter | WY Sump Pump ≈ Value |

|---|---|

| Flow | 30–600 m³/h (duty-dependent) |

| Head | 6–45 m |

| Max solids size | up to ≈ 38 mm |

| Slurry density | up to ≈ 1.6–1.8 SG |

| Materials | High-chrome iron (e.g., A05), rubber-lined options |

| Submergence | ≈ 0.7–2.5 m (depending on build) |

| Power pairing | 11–90 kW typical |

| Temp window | 0–80°C |

Where it’s used (from my notebook)

- Mining: mill sumps, tailings transfer, cyclone feed standby.

- Sand & aggregates: classifier underflow, fines recovery.

- Steel & coal prep: scale pits, dense media loops.

- Chemical & minerals: neutralization sumps, process spills.

- Municipal: grit sumps and storm overflow pits.

How it’s built and verified

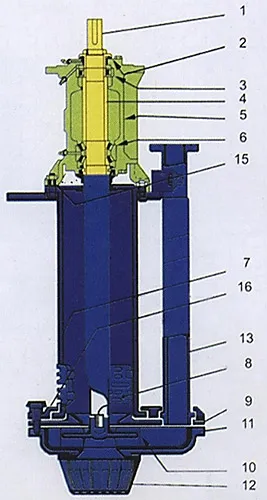

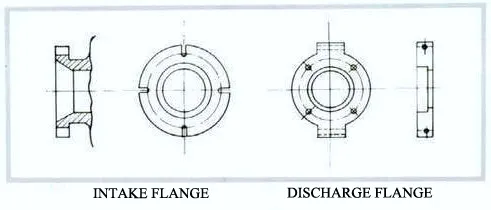

Materials: high-chrome white iron (ASTM A532 Class IIIA) for wet ends; elastomer options where chemistry demands; heavy-wall casing. Methods: precision casting, heat treatment, CNC machining, impeller dynamic balancing, and cantilever shaft alignment checks. Testing: hydrostatic shell test; performance checked to ISO 9906 (Grade 2B) or GB/T 3216 equivalents; vibration to ISO 10816 guidelines. Typical service life? In moderately abrasive slurry, I’ve seen 9–18 months between wet-end swaps; in harsh silica, plan for shorter intervals but longer than soft-steel builds.

A few field notes

- Hebei iron ore: WYJ variant reduced seal-water use to zero; availability rose ≈ 3.5%.

- Texas frac sand: elastomer-lined unit handled 30% solids; wear rate dropped ≈ 18% vs prior pump.

- Indonesia mill: longer shaft build solved sump foaming; operators praised the “forgiving” NPSH behavior.

Vendor comparison (quick take)

| Criteria | WY Sump Pump (AIER) | Vendor A (budget) | Vendor B (premium) |

|---|---|---|---|

| Seal water needed | No | Often | No |

| Materials hardness | High-chrome A05 option | Mixed | High |

| Customization depth | Strong | Limited | Strong |

| Lifecycle cost (≈) | Low–Mid | Low upfront | High upfront |

Customization, certifications, feedback

Options: shaft length, submergence, impeller type, wear materials, suction strainers, and motor/VFD pairing. Certifications typically include ISO 9001 QMS; performance tests per ISO 9906 or GB/T 3216; material certs to ASTM. One maintenance lead told me, “We swapped to WY mainly to stop babysitting seals.” If you’re shortlisting a submersible well pump manufacturer, check test curves vs. your slurry SG and ask for wear-part lead times.

Final thought: choosing a submersible well pump manufacturer isn’t just about headline flow and head. It’s metallurgy, sealing philosophy (or none), and the service culture behind the crate.

Authoritative references

- ISO 9906:2012 – Rotodynamic pumps, Hydraulic performance acceptance tests.

- GB/T 3216 – Rotodynamic pumps, Hydraulic performance tests (China standard).

- ANSI/HI Pump Standards (Hydraulic Institute), Slurry pump guidelines.

- ASTM A532 – Abrasion-resistant cast irons for slurry service.

- ISO 9001:2015 – Quality management systems for manufacturing operations.

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025