Nov . 24, 2024 00:59 Back to list

submerged slurry pump manufacturer

Understanding Submerged Slurry Pumps and Their Manufacturers

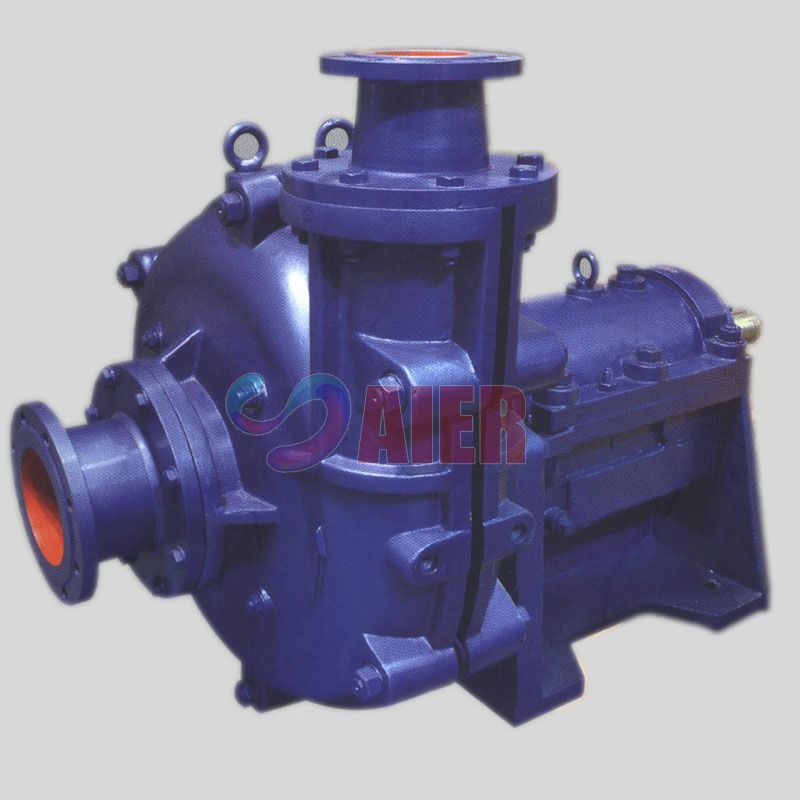

Submerged slurry pumps play a critical role in various industries where the transport of abrasive, viscous, or solid-laden fluids is necessary. These pumps are designed to operate under challenging conditions, often fully submerged in the slurry they are meant to pump. Given their importance, understanding the manufacturers of these specialized pumps can provide insight into their selection, application, and overall utilization.

What Is a Submerged Slurry Pump?

A submerged slurry pump is a type of centrifugal pump that transports slurry—a mixture of solid particles and liquid—by converting rotational energy into hydraulic energy. This pump is typically installed underwater in applications requiring the movement of materials like coal, sand, cement, minerals, and more. Its submersion allows it to handle high-density and highly abrasive mixtures more effectively than conventional pumps.

Applications of Submerged Slurry Pumps

These pumps are primarily used in mining, steel production, construction, and wastewater treatment industries. In mining, for example, submerged slurry pumps help transport minerals from one point to another through slurries generated during extraction processes. In construction, they may be employed for dewatering applications where solids need to be removed from the construction site.

Key Features and Benefits

1. Durability Submerged slurry pumps are built to withstand harsh conditions. They are often made from high-strength materials that resist wear from abrasive solids, ensuring a longer service life. 2. Efficiency Designed to handle high volumes of solids and liquids, these pumps can maintain efficiency even in challenging operational scenarios. The hydraulic efficiency leads to reduced energy consumption.

submerged slurry pump manufacturer

4. Reduced Maintenance With fewer moving parts compared to other pump types, submerged slurry pumps often require less maintenance, thus lowering operational costs.

Choosing the Right Manufacturer

When selecting a submerged slurry pump, it’s crucial to consider the reputation and expertise of the manufacturer. Leading manufacturers typically provide a range of products tailored to specific applications, backed by extensive research and development.

1. Experience Established manufacturers with a long history in the industry often have more experience dealing with various challenges that can arise in slurry pumping. They are likely to have tested and improved their designs over the years and can offer reliable solutions.

2. Quality Assurance The best manufacturers adhere to stringent quality control measures, ensuring that every pump meets high-performance standards. Certifications from recognized organizations can provide confidence in product quality.

3. Technical Support Renowned manufacturers frequently offer comprehensive customer support, from selecting the right pump for a specific application to providing after-sales services like maintenance and repair.

4. Innovation The slurry pump industry is continuously evolving, with manufacturers investing in innovative solutions to enhance performance and efficiency. It's beneficial to partner with companies that are on the cutting edge of technology, ensuring you benefit from the latest advancements.

Conclusion

Submerged slurry pumps are indispensable tools within various industries, known for their efficiency in moving difficult materials. Choosing the right manufacturer is just as important as the pump itself. By considering factors like experience, quality, support, and innovation, industries can better navigate their specific needs for slurry pumping solutions. As technology continues to evolve, we can expect to see even more robust and efficient designs emerging, further optimizing the processes involving submerged slurry pumps. Selecting the right manufacturer will ensure that businesses benefit from these advancements while minimizing downtime and maximizing productivity.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025