Dec . 14, 2024 20:52 Back to list

Efficient Solutions for Underwater Slurry Pumping Applications and Technologies

Submerged Slurry Pump An Overview

Submerged slurry pumps play a critical role in various industrial applications, particularly in mining, dredging, and slurry transportation. These specialized pumps are designed to handle abrasive slurries that contain solids at various concentrations. Unlike standard pumps, submerged slurry pumps operate efficiently in a submerged condition, which increases their versatility and operational effectiveness.

Design and Features

Submerged slurry pumps are characterized by their robust construction and innovative features. Typically made from high-chrome alloy materials or rubber-lined components, these pumps are designed to withstand the harsh conditions associated with moving slurries. A key feature of these pumps is their ability to operate beneath the surface of the slurry, helping to mitigate issues related to cavitation and ensuring a consistent flow of materials.

The design of submerged slurry pumps often includes a wide inlet opening, which allows for the smooth intake of thick or viscous slurries without clogging. Moreover, the impeller and volute are engineered to enhance the pump's efficiency and longevity. Some models even include wear-resistant liners, which help reduce the need for frequent maintenance and prolong the lifespan of the pump.

Applications

Submerged slurry pumps are used in a variety of applications across multiple industries. In mining operations, these pumps are essential for transporting slurries from ore extraction processes to processing facilities. The abrasive nature of the materials involved necessitates durable pumping solutions, making submerged slurry pumps an ideal choice.

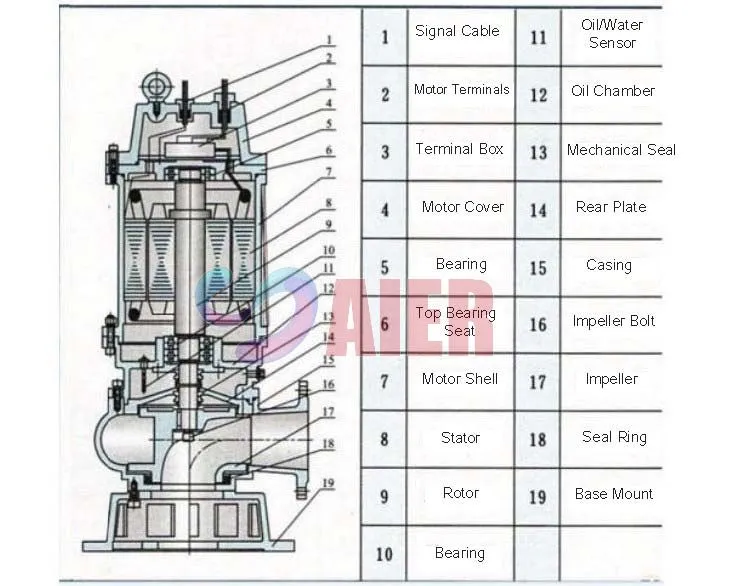

submerged slurry pump

In dredging operations, these pumps are used to remove sediment and debris from waterways. They can handle a wide range of materials, including sand, silt, and gravel, making them suitable for environmental restoration projects and marine construction activities. Furthermore, in the wastewater treatment industry, submerged slurry pumps are utilized to manage and transport sludge, ensuring efficient treatment processes.

Advantages

The advantages of utilizing submerged slurry pumps are numerous. Their ability to handle abrasive and corrosive materials without significant wear-and-tear makes them a cost-effective solution in the long run. Additionally, their submerged operation minimizes maintenance downtime, as there are no exposed rotating components that could be damaged by environmental factors.

Another significant advantage is their energy efficiency. Submerged slurry pumps are often designed with advanced hydraulics that improve flow rates and reduce operational costs. This efficiency is critical for industrial operations where energy consumption directly impacts profitability.

Conclusion

In conclusion, submerged slurry pumps are a vital component of industrial processes that involve the handling of abrasive materials. Their specialized design, robust construction, and versatility position them as an essential tool in mining, dredging, and wastewater management. As industries continue to evolve and demands for efficiency grow, submerged slurry pumps are likely to remain at the forefront of technological advancements in fluid transfer solutions. Understanding the features and applications of these pumps is vital for professionals seeking to optimize their operational capabilities and ensure long-term sustainability in their processes. Through careful selection and application, submerged slurry pumps can significantly enhance productivity while reducing maintenance and operating costs.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025