Dec . 01, 2024 17:03 Back to list

Compact Centrifugal Sewage Pump Manufacturer for Efficient Wastewater Solutions

The Role of Small Centrifugal Sewage Pump Factories in Modern Water Management

In recent years, the need for efficient water management systems has become increasingly critical. With the rising importance of environmental conservation and sustainable practices, small centrifugal sewage pump factories have emerged as a vital component in the treatment and management of wastewater. These factories not only produce essential equipment but also contribute significantly to the broader objective of safeguarding public health and maintaining a clean environment.

Understanding Centrifugal Sewage Pumps

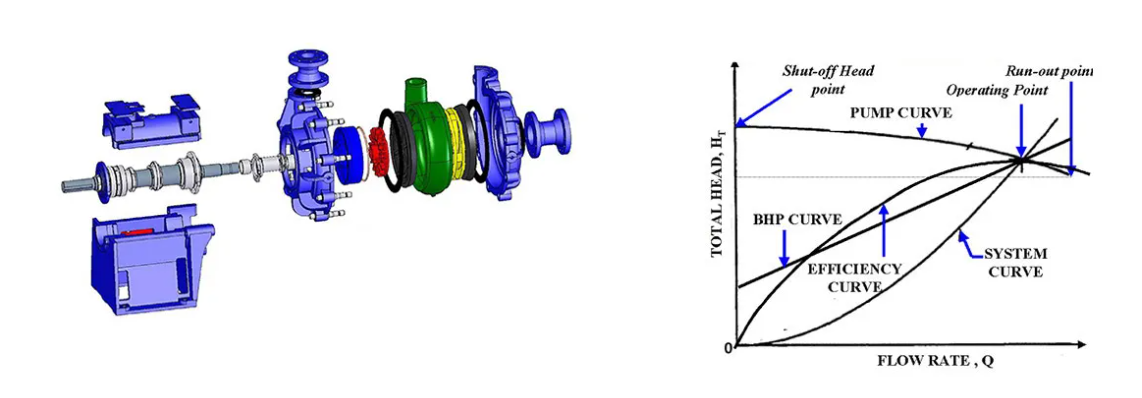

Centrifugal sewage pumps are designed to handle wastewater, including solids, and are commonly used in municipal and industrial applications. The fundamental principle behind these pumps is centrifugal force, which accelerates the fluid and pushes it through the pump system. The unique design of the impeller allows these pumps to process a variety of waste materials, making them indispensable in sewage systems where traditional pumps may falter.

Small centrifugal sewage pump factories specialize in the manufacturing of these essential devices. By focusing on smaller production scales, these factories can innovate rapidly and cater to specific regional needs without the overhead costs associated with larger manufacturers. This allows them to create customized solutions that meet the demands of diverse environments, from rural applications to urban developments.

Importance of Small Factories

Small factories play an essential role in enhancing local economies and fostering innovation. They often focus on specialized markets, providing more tailored products that meet specific requirements. This flexibility can lead to improved efficiency in the manufacturing process and greater responsiveness to customer feedback.

Moreover, small factories typically have a closer connection to their communities. This local presence enables them to understand and address the unique challenges faced by their customers, such as fluctuating water levels, the nature of waste, and varying regulations. This understanding can translate into superior customer service and better product offerings.

Environmental Considerations

small centrifugal sewage pump factory

The significance of small centrifugal sewage pump factories extends beyond economic factors; they are also crucial players in environmental conservation efforts. These factories are equipped to produce pumps that are designed for energy efficiency, which helps reduce the overall carbon footprint associated with wastewater management. Moreover, advances in technology enable the production of pumps that minimize water wastage, further supporting sustainable practices.

Innovative designs such as submersible pumps and automatic control systems have emerged from these factories, allowing for real-time monitoring and management of sewage systems. By decreasing the risk of overflows and blockages, these advancements not only protect local ecosystems but also ensure regulatory compliance.

Technology and Innovation

The rise of smart technology has also influenced small centrifugal sewage pump factories. Many factories are integrating smart features into their products, such as IoT (Internet of Things) connectivity. This technology allows for remote monitoring and control, enabling operators to optimize performance and reduce maintenance costs. Predictive analytics can help factories identify potential issues before they become critical, increasing the reliability of sewage systems and reducing downtime.

Furthermore, small factories often pioneer low-cost prototypes that can be tested rapidly in the field. This approach allows for quicker iterations in design and technology, ensuring that products remain relevant and effective in a constantly evolving market.

Challenges and Future Prospects

Despite their advantages, small centrifugal sewage pump factories face challenges that must be addressed. Competition from larger manufacturers with greater resources can limit their market share, and fluctuating material prices may impact profitability. However, by focusing on niche markets and leveraging their strengths in customization and local service, these factories can carve out a significant position in the industry.

Looking ahead, as global urbanization and the challenges associated with managing wastewater continue to grow, the demand for efficient sewage management solutions will only increase. Small centrifugal sewage pump factories are well-positioned to meet this demand. By embracing innovation and maintaining a strong connection to their communities, they can contribute to the development of more sustainable and effective water management systems.

In conclusion, small centrifugal sewage pump factories play a crucial role in modern water management. Their ability to innovate, focus on community needs, and promote environmentally friendly practices positions them as essential players in the fight for cleaner, more efficient wastewater management solutions. As these factories continue to evolve, they will undoubtedly remain at the forefront of tackling some of the most pressing water-related challenges of our time.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025