Nov . 26, 2024 12:31 Back to list

Rubber Manufacturing for Slurry Pumps in Industrial Applications and Solutions

The Importance of Rubber Slurry Pumps in Industrial Applications

In the world of industrial processing, the transportation of abrasive and corrosive materials is a critical task. Slurry pumps have emerged as essential equipment in this realm, particularly rubber slurry pumps. These pumps are specifically designed to handle slurries, a mixture of solids and liquids, making them indispensable in various industrial applications, including mining, metallurgy, and wastewater treatment.

One of the primary advantages of rubber slurry pumps is their exceptional resistance to abrasion. Slurries often contain solid particles that can wear down conventional pump materials. However, rubber, often used in designing the components of these pumps, offers significant durability against wear. Rubber materials can withstand the harsh conditions of transporting abrasive slurries, ensuring a longer operational lifespan and reducing the frequency of maintenance and part replacement.

The Importance of Rubber Slurry Pumps in Industrial Applications

The design of rubber slurry pumps is also worth noting. They are often built with an efficient hydraulic design that minimizes turbulence and maximizes flow efficiency. This results in reduced energy consumption, which is a significant consideration for many industrial operations. Moreover, the versatility of rubber slurry pumps enables them to handle a range of slurry concentrations and types, making them suitable for various processes across different industries.

slurry pump rubber factory

When selecting a rubber slurry pump, it's crucial to consider the pump's specific application. Factors such as the characteristics of the slurry, including viscosity, particle size, and concentration, play a significant role in determining the right pump design. Many manufacturers provide customization options, allowing for tailored solutions that meet specific operational needs.

In addition to the practical benefits, investing in high-quality rubber slurry pumps can lead to overall cost savings for businesses. Reduced downtime due to fewer maintenance needs, combined with improved energy efficiency, allows companies to enhance productivity and profitability. Moreover, the ability to reliably transport abrasive slurries reduces the risk of damage to other equipment in the processing line, further minimizing unexpected repair costs.

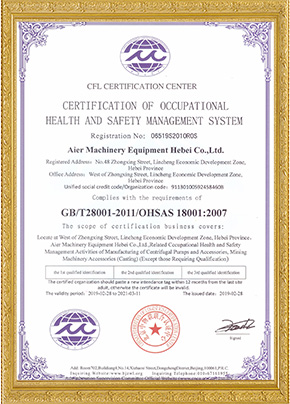

The manufacturing of rubber slurry pumps is another key aspect of this industry. A dedicated rubber slurry pump factory employs advanced materials and production techniques to ensure high-quality output. Quality control is paramount—every pump must meet rigorous standards to ensure it can perform reliably in demanding environments. Manufacturers often conduct extensive testing and research to enhance the properties of the rubber used, resulting in pumps that can withstand even the most challenging conditions.

Moreover, the global demand for rubber slurry pumps continues to grow, driven by increasing industrial activities and the need for efficient material handling solutions. As industries evolve and seek more sustainable and cost-effective practices, the role of rubber slurry pumps will undoubtedly expand.

In conclusion, rubber slurry pumps play a vital role in various industrial sectors, offering durability, chemical resistance, and efficiency. As technology progresses and industries evolve, the continued development and optimization of these pumps are essential for meeting the ever-growing challenges of material transportation. Investing in high-quality rubber slurry pumps not only ensures reliable operation but also contributes to the overall productivity and sustainability of industrial processes.

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025