Feb . 08, 2025 06:32 Back to list

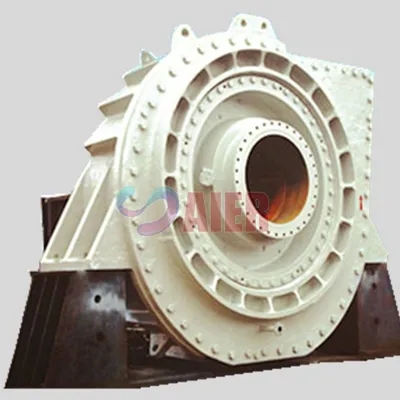

expeller ring

Slurry pumps and mud screw pumps play a pivotal role in various industries, driving efficiency and reliability in the management of materials. As a seasoned expert in the field of industrial pump technology, I understand the impact these specialized tools can have on operations. My experience with slurry pump and mud screw pump manufacturers has equipped me with the knowledge to discuss their importance for businesses aiming for robust performance and longevity in demanding environments.

Furthermore, these manufacturers often offer customizable solutions tailored to a specific industry or application. This customization is crucial, as each industry poses unique challenges that a one-size-fits-all solution cannot address effectively. For instance, a manufacturer catering to the oil industry may offer pumps with superior corrosion-resistant coatings to handle aggressive fluids, prolonging the equipment's operational lifespan and safeguarding investments. Choosing a pump from a reputable manufacturer is also a decision grounded in building trust. The assurance of quality, backed by warranties and comprehensive after-sales service, sets the best manufacturers apart from competitors. Their expertise is not just in crafting products, but in advising clients on optimal configurations and maintenance practices, based on years of industry-specific knowledge. Moreover, partnerships with top manufacturers yield insights into innovations and industry trends. As industries evolve, so do the demands on pump technology. The leading-edge manufacturers I have worked with often invest in sustainable technologies and the development of eco-friendly products, aligning with global trends towards sustainable and responsible industry practices. In conclusion, slurry pumps and mud screw pumps are essential for the efficient handling of challenging materials in a variety of industries. Collaborating with an authoritative manufacturer ensures access to the most advanced technologies and reliable products, engineered to meet the rigorous demands of modern industrial operations. Leveraging the expertise and commitment of such manufacturers leads to enhanced productivity, reduced costs, and sustainable practices that future-proof operations. This partnership is not just a transaction but a strategic alliance that positions businesses to harness the full potential of their processes.

Furthermore, these manufacturers often offer customizable solutions tailored to a specific industry or application. This customization is crucial, as each industry poses unique challenges that a one-size-fits-all solution cannot address effectively. For instance, a manufacturer catering to the oil industry may offer pumps with superior corrosion-resistant coatings to handle aggressive fluids, prolonging the equipment's operational lifespan and safeguarding investments. Choosing a pump from a reputable manufacturer is also a decision grounded in building trust. The assurance of quality, backed by warranties and comprehensive after-sales service, sets the best manufacturers apart from competitors. Their expertise is not just in crafting products, but in advising clients on optimal configurations and maintenance practices, based on years of industry-specific knowledge. Moreover, partnerships with top manufacturers yield insights into innovations and industry trends. As industries evolve, so do the demands on pump technology. The leading-edge manufacturers I have worked with often invest in sustainable technologies and the development of eco-friendly products, aligning with global trends towards sustainable and responsible industry practices. In conclusion, slurry pumps and mud screw pumps are essential for the efficient handling of challenging materials in a variety of industries. Collaborating with an authoritative manufacturer ensures access to the most advanced technologies and reliable products, engineered to meet the rigorous demands of modern industrial operations. Leveraging the expertise and commitment of such manufacturers leads to enhanced productivity, reduced costs, and sustainable practices that future-proof operations. This partnership is not just a transaction but a strategic alliance that positions businesses to harness the full potential of their processes.

Next:

Latest news

-

Top China Submersible Slurry Pump Supplier Durable & Efficient Solutions

NewsMay.17,2025

-

Submersible Pump Spares Manufacturer High-Quality & Durable Components

NewsMay.17,2025

-

Vertical Centrifugal Sump Pump Supplier China Factory Solutions

NewsMay.16,2025

-

Vertical Spindle Slurry Pump Suppliers High-Quality China Manufacturers

NewsMay.16,2025

-

High-Quality Casting Submersible Pump Parts Manufacturer Durable Solutions

NewsMay.16,2025

-

Vertical Sump & Mud Screw Slurry Pump Company Durable Solutions

NewsMay.15,2025