Jan . 15, 2025 03:58 Back to list

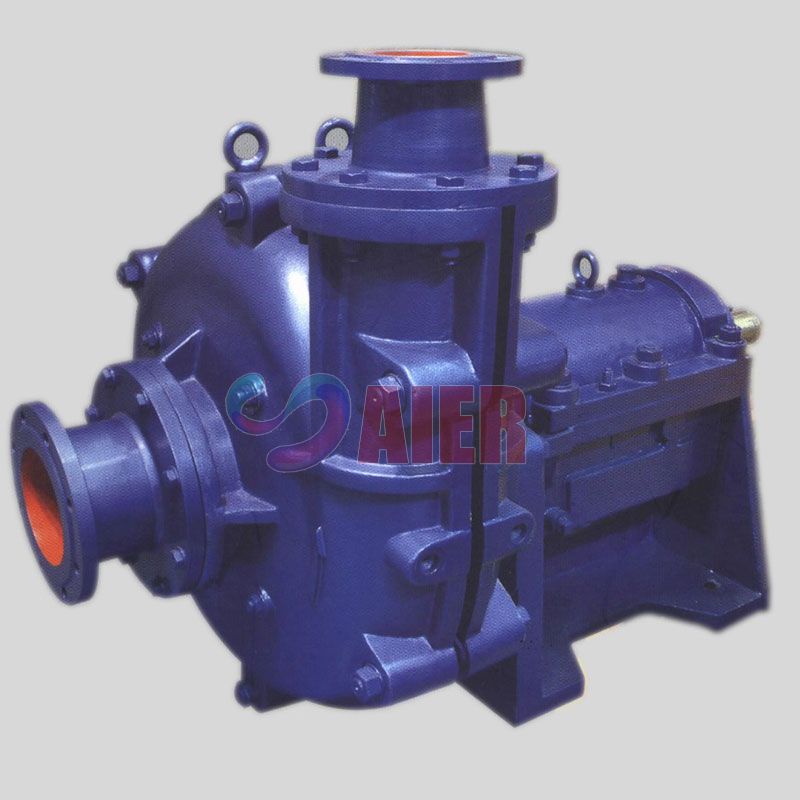

close impeller type slurry pump factory

In the bustling industrial landscape of Indonesia, slurry pumps play a critical role in various sectors, including mining, construction, and manufacturing. These robust machines are engineered to handle the transfer of thick, viscous fluids imbued with solid particles. The demand for high-quality slurry pumps in Indonesia has been on a steady rise, owing to the country's expanding industrial base and the need for efficient material handling solutions.

Trustworthiness in slurry pump suppliers in Indonesia is built through a strong track record of delivering reliable products and excellent customer service. By fostering transparency in operations and maintaining open lines of communication, suppliers can assure clients of the quality and dependability of their products. Additionally, offering comprehensive after-sales support, including maintenance services and a ready supply of spare parts, fortifies the confidence industries have in their chosen slurry pump solutions. Experience plays a pivotal role in shaping the effectiveness of slurry pump applications in Indonesia. Through decades of industry involvement, experts have garnered deep insights into the best practices for slurry pump implementation, from proper installation techniques to regular maintenance protocols. This accumulated knowledge enables businesses to optimize their material handling processes, improving efficiency and productivity. In conclusion, the slurry pump industry in Indonesia thrives on a foundation of experience, expertise, authoritativeness, and trustworthiness. These pillars support the continuous growth and innovation of slurry pump solutions tailored to meet the distinct needs of Indonesian industries. As the industrial sector continues to evolve, the demand for advanced, reliable, and efficient slurry pumps will only increase, driving further innovation and development in this essential field. By focusing on these core aspects, slurry pump suppliers can ensure they not only meet but exceed the expectations of their clients, cementing their position as leaders in the Indonesian market. The ability to deliver tailor-made, high-quality slurry pump solutions will be key to sustaining success in this competitive landscape.

Trustworthiness in slurry pump suppliers in Indonesia is built through a strong track record of delivering reliable products and excellent customer service. By fostering transparency in operations and maintaining open lines of communication, suppliers can assure clients of the quality and dependability of their products. Additionally, offering comprehensive after-sales support, including maintenance services and a ready supply of spare parts, fortifies the confidence industries have in their chosen slurry pump solutions. Experience plays a pivotal role in shaping the effectiveness of slurry pump applications in Indonesia. Through decades of industry involvement, experts have garnered deep insights into the best practices for slurry pump implementation, from proper installation techniques to regular maintenance protocols. This accumulated knowledge enables businesses to optimize their material handling processes, improving efficiency and productivity. In conclusion, the slurry pump industry in Indonesia thrives on a foundation of experience, expertise, authoritativeness, and trustworthiness. These pillars support the continuous growth and innovation of slurry pump solutions tailored to meet the distinct needs of Indonesian industries. As the industrial sector continues to evolve, the demand for advanced, reliable, and efficient slurry pumps will only increase, driving further innovation and development in this essential field. By focusing on these core aspects, slurry pump suppliers can ensure they not only meet but exceed the expectations of their clients, cementing their position as leaders in the Indonesian market. The ability to deliver tailor-made, high-quality slurry pump solutions will be key to sustaining success in this competitive landscape.

Next:

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025