Dec . 06, 2024 19:45 Back to list

slurry pump impeller suppliers

The Importance of Slurry Pump Impellers and Choosing the Right Suppliers

Slurry pumps are critical components in various industries, particularly in mining, mineral processing, and wastewater management. The efficiency and durability of these pumps largely depend on their impellers, which are designed to handle abrasive and viscous slurries. As such, selecting the right slurry pump impeller suppliers is essential for ensuring optimal performance and minimizing downtime.

Understanding Slurry Pump Impellers

Slurry pump impellers are designed to transfer solids-laden fluids. Unlike standard liquid pumps, slurry pumps are built to handle the wear and tear caused by the abrasive materials they transport. The impeller is the rotating part that imparts kinetic energy to the slurry, hence it is crucial that it is manufactured from high-quality materials that can withstand these harsh conditions.

The efficiency of a slurry pump largely hinges on the design and material of the impeller. Different types of impellers are used based on the specific application, including open, closed, and semi-closed designs. The choice of design affects the pump’s performance, wear rates, and the types of slurries it can effectively manage.

Key Factors to Consider When Choosing Suppliers

When sourcing slurry pump impellers, businesses should consider several factors to ensure they select a reliable supplier

1. Material Quality The material used in the manufacturing of impellers significantly impacts their durability and resistance to wear. Common materials include high chrome alloys, rubber, and polyurethane. Suppliers with a reputable history of providing high-quality materials are vital.

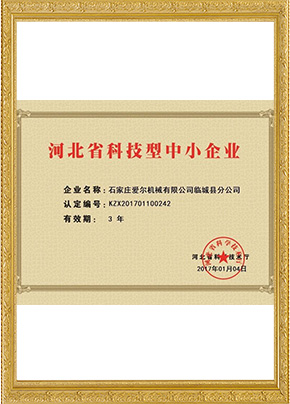

2. Manufacturing Standards It’s essential that suppliers adhere to recognized manufacturing standards, such as ISO certifications. These standards ensure that the impellers are produced with quality control measures in place, which can lead to longer service life and better performance.

slurry pump impeller suppliers

3. Customization Options Different applications may require unique design specifications. Suppliers who offer customization options can tailor impellers to meet specific operational needs, thus enhancing efficiency and reducing the risk of premature failure.

4. Technical Support Reliable suppliers should provide adequate support, including expert advice on the selection and operation of impellers. This is crucial for industries that frequently deal with varying slurry compositions.

5. Reputation and Experience Suppliers with a proven track record and long-standing experience in the industry are often more reliable. Customer reviews and case studies can provide insights into a supplier's capabilities and reliability.

6. Cost vs. Value While price is an important factor, it should not be the sole determinant. A lower cost may come at the expense of quality and durability. It’s essential to assess the overall value, including factors like performance lifespan and maintenance costs.

The Role of Technology in Impeller Design

With technological advancements, the manufacturing of slurry pump impellers has evolved significantly. The use of computational fluid dynamics (CFD) in the design process allows for better efficiency and performance analysis. Innovative materials and coatings are also being developed to enhance the durability of impellers, making them more resilient against abrasion and corrosion.

Conclusion

Choosing the right slurry pump impeller suppliers is paramount for any operation dealing with slurries. The quality of the impellers not only affects the operational efficiency of slurry pumps but also impacts overall productivity and maintenance costs. By considering factors such as material quality, manufacturing standards, customization options, and supplier reputation, businesses can make informed decisions that lead to improved performance and reduced downtime.

Investing time and resources in selecting the best suppliers will undoubtedly yield significant returns, ensuring that slurry pumping systems operate efficiently and effectively, even under the most challenging conditions. As industries continue to evolve, partnering with suppliers who are adaptive and innovative will be crucial for sustained success.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025