Oct . 05, 2024 21:14 Back to list

Reliable Suppliers of High-Quality Slurry Pump Impellers for Efficient Fluid Handling

The Importance of Selecting the Right Slurry Pump Impeller Supplier

When it comes to industries dealing with abrasive fluids, the choice of slurry pumps and their components plays a critical role in operational efficiency and longevity. One key component that significantly affects the performance of slurry pumps is the impeller. Therefore, selecting a reliable slurry pump impeller supplier is essential for ensuring optimal performance and durability.

Slurry pumps are designed to transport a variety of materials, ranging from coal and minerals to wastewater sludge. These pumps are often subjected to high wear and tear due to the abrasive nature of the materials they handle. Consequently, the impeller, which imparts energy to the slurry, must be robust, well-designed, and manufactured from materials that can withstand the harsh operating conditions.

Choosing the right supplier for slurry pump impellers involves several factors. First, consider the experience and reputation of the supplier in the industry. A supplier with a long-standing history and positive reviews from clients will likely provide products that meet the required standards of quality and performance. Additionally, check if they specialize in manufacturing impellers for your specific type of slurry pump. Specialization often indicates a greater understanding of the specific needs and challenges associated with your application.

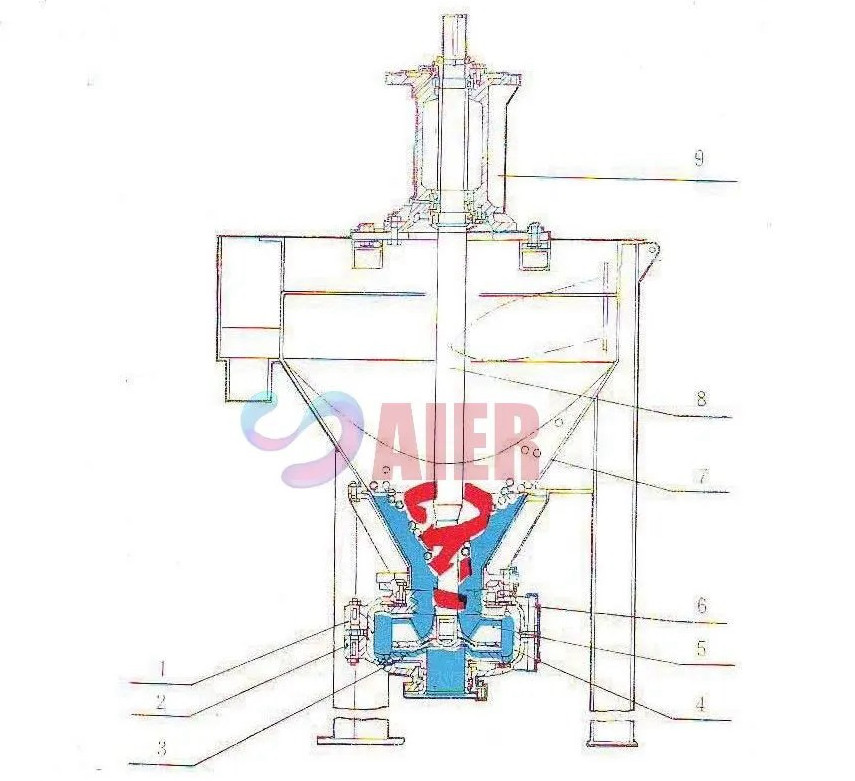

slurry pump impeller supplier

Material selection is another crucial aspect. High-quality impellers are typically made from durable materials such as high-chrome alloys or rubber compounds, providing superior resistance to abrasion and corrosion. A reputable supplier will be able to offer a range of materials suited for different types of slurries, ensuring that the impeller can withstand the specific conditions of the environment in which it will operate.

Moreover, innovation and technology play a vital role in the development of slurry pump impellers. Suppliers that invest in research and development tend to offer advanced designs that enhance efficiency and reduce energy consumption. Look for suppliers who utilize cutting-edge manufacturing techniques, such as precision casting or 3D printing, to produce high-quality impellers with tighter tolerances for improved performance.

Customer support and service are equally important when selecting a supplier. A reliable supplier should not only provide high-quality products but also offer technical support, guidance on installation, and assistance with any operational issues that may arise. Strong after-sales support can significantly prolong the lifespan of your slurry pump system and optimize its efficiency.

In conclusion, selecting the right slurry pump impeller supplier is a crucial decision that can greatly influence the operational success of your pumping system. By considering factors such as experience, material quality, technological innovation, and customer support, you can ensure that you make an informed choice, leading to enhanced performance and reliability in your slurry handling operations.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025