Feb . 12, 2025 11:02 Back to list

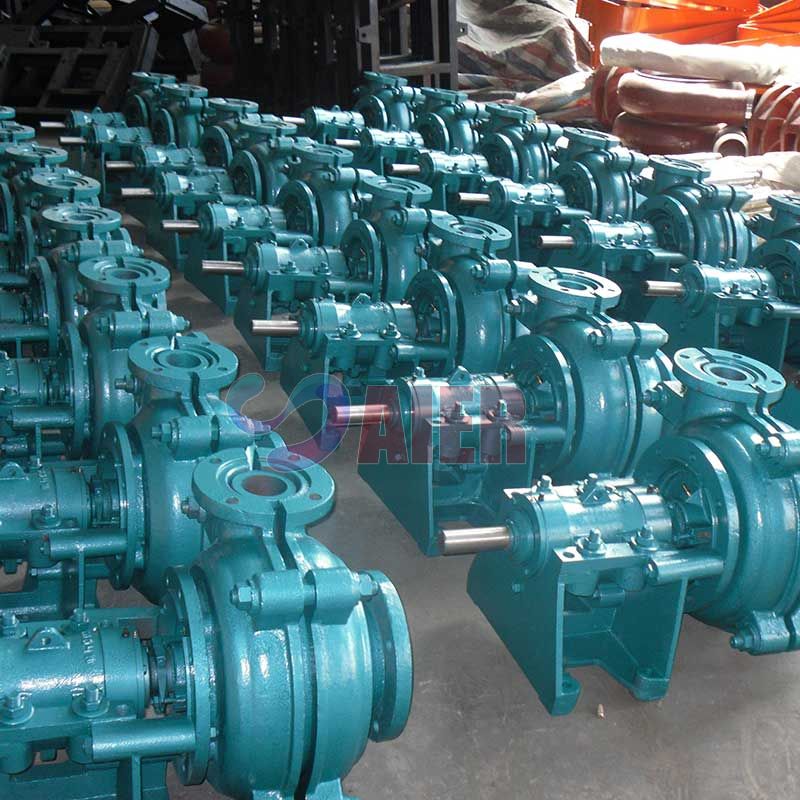

steel mill slurry pump made in china

Slurry pumps hold significant importance in various industries, ranging from mining to chemical processing, owing to their ability to handle abrasive and corrosive fluids. A key component of these pumps is the impeller, which plays a crucial role in determining the pump's efficiency and longevity. Impellers manufactured in China are increasingly gaining traction due to their exceptional quality, innovative designs, and cost-effectiveness.

Moreover, Chinese manufacturers are at the forefront of innovation in impeller design. With a focus on aerodynamic efficiency, they craft impellers that maximize fluid flow while minimizing energy consumption. This innovative approach not only optimizes pump performance but also aligns with global sustainability efforts by reducing energy usage. The emphasis on sustainable solutions without compromising on performance further bolsters the credibility and authority of Chinese impeller manufacturers in the global market. Trustworthiness in any product stems from consistent quality and satisfactory user experiences. Chinese impeller manufacturers are known for their commitment to reliability and post-purchase support. Many have implemented robust customer service systems that ensure clients receive comprehensive support, from selecting the appropriate impeller design to technical support during operation. Customer testimonials and long-term partnerships with global brands further underscore the trust that industries worldwide place in Chinese-made impellers. The growing demand for slurry pumps with efficient impellers necessitates a choice that optimally balances cost, performance, and longevity. Chinese manufacturers offer this balance, providing impellers that not only compete with but often surpass those produced in other countries. They achieve this by leveraging economies of scale, advanced manufacturing techniques, and a strategic focus on research and development. In conclusion, the slurry pump impeller market is witnessing a significant shift toward Chinese-made products, thanks to their blend of quality craftsmanship, innovative design, and cost efficiency. For industries that operate in harsh conditions, utilizing a reliable slurry pump impeller can mean the difference between seamless operations and costly downtimes. By choosing an impeller produced in China, companies can rely on a product that embodies excellence in manufacturing and performance, backed by a country renowned for its industrial prowess and commitment to quality. This makes them a worthy consideration for any organization seeking to enhance the reliability and efficiency of their pumping systems.

Moreover, Chinese manufacturers are at the forefront of innovation in impeller design. With a focus on aerodynamic efficiency, they craft impellers that maximize fluid flow while minimizing energy consumption. This innovative approach not only optimizes pump performance but also aligns with global sustainability efforts by reducing energy usage. The emphasis on sustainable solutions without compromising on performance further bolsters the credibility and authority of Chinese impeller manufacturers in the global market. Trustworthiness in any product stems from consistent quality and satisfactory user experiences. Chinese impeller manufacturers are known for their commitment to reliability and post-purchase support. Many have implemented robust customer service systems that ensure clients receive comprehensive support, from selecting the appropriate impeller design to technical support during operation. Customer testimonials and long-term partnerships with global brands further underscore the trust that industries worldwide place in Chinese-made impellers. The growing demand for slurry pumps with efficient impellers necessitates a choice that optimally balances cost, performance, and longevity. Chinese manufacturers offer this balance, providing impellers that not only compete with but often surpass those produced in other countries. They achieve this by leveraging economies of scale, advanced manufacturing techniques, and a strategic focus on research and development. In conclusion, the slurry pump impeller market is witnessing a significant shift toward Chinese-made products, thanks to their blend of quality craftsmanship, innovative design, and cost efficiency. For industries that operate in harsh conditions, utilizing a reliable slurry pump impeller can mean the difference between seamless operations and costly downtimes. By choosing an impeller produced in China, companies can rely on a product that embodies excellence in manufacturing and performance, backed by a country renowned for its industrial prowess and commitment to quality. This makes them a worthy consideration for any organization seeking to enhance the reliability and efficiency of their pumping systems.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025