Jan . 31, 2025 05:38 Back to list

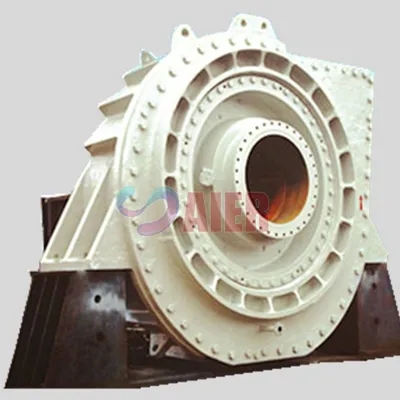

High Chromium Alloy Wet Ends

Slurry pumps play a critical role in the vapor blasting process, a technique renowned for its gentle yet effective surface treatment capabilities. Vapor blasting, also known as wet blasting or liquid honing, has gained popularity across various industries including automotive, aerospace, and restoration due to its ability to clean, deburr, and finish surfaces without damaging the substrate.

Professionals in the field emphasize the importance of regular maintenance and monitoring to extend the life and performance of slurry pumps. Implementing a preventative maintenance schedule, which includes inspecting seals, bearings, and pump liners, can prevent unexpected failures. Advanced slurry pumps now come equipped with sensors and IoT capabilities to give real-time data on performance, allowing operators to make informed decisions and preemptively address issues. Beyond technical considerations, user experience and ease of operation are paramount. The best slurry pumps are designed with intuitive controls and ergonomic features that reduce operator fatigue and training time. A user-friendly interface, complemented by comprehensive customer support, ensures that even those new to vapor blasting can operate the equipment efficiently. In recent years, advancements in pump technology have made significant strides in energy efficiency. Slurry pumps for vapor blasting are now engineered to minimize power consumption, thereby reducing operational costs and environmental impact. By choosing an energy-efficient pump, companies can contribute to sustainable practices while enhancing their bottom line. Industry experts also underscore the importance of working with reputable manufacturers when procuring slurry pumps for vapor blasting. Companies with a proven track record provide not only high-quality equipment but also valuable consultation services to tailor pump solutions to specific needs. Furthermore, they offer extensive warranties and follow-up support, which instill confidence in their products' reliability and performance. In conclusion, the selection and maintenance of slurry pumps are critical components in the vapor blasting process. By focusing on factors such as pump material, design, and technology, operators can optimize their equipment's performance, ensuring efficient and effective surface treatment. A focus on quality, backed by expert guidance and support, ensures that the slurry pump remains a reliable workhorse in the vapor blasting arena.

Professionals in the field emphasize the importance of regular maintenance and monitoring to extend the life and performance of slurry pumps. Implementing a preventative maintenance schedule, which includes inspecting seals, bearings, and pump liners, can prevent unexpected failures. Advanced slurry pumps now come equipped with sensors and IoT capabilities to give real-time data on performance, allowing operators to make informed decisions and preemptively address issues. Beyond technical considerations, user experience and ease of operation are paramount. The best slurry pumps are designed with intuitive controls and ergonomic features that reduce operator fatigue and training time. A user-friendly interface, complemented by comprehensive customer support, ensures that even those new to vapor blasting can operate the equipment efficiently. In recent years, advancements in pump technology have made significant strides in energy efficiency. Slurry pumps for vapor blasting are now engineered to minimize power consumption, thereby reducing operational costs and environmental impact. By choosing an energy-efficient pump, companies can contribute to sustainable practices while enhancing their bottom line. Industry experts also underscore the importance of working with reputable manufacturers when procuring slurry pumps for vapor blasting. Companies with a proven track record provide not only high-quality equipment but also valuable consultation services to tailor pump solutions to specific needs. Furthermore, they offer extensive warranties and follow-up support, which instill confidence in their products' reliability and performance. In conclusion, the selection and maintenance of slurry pumps are critical components in the vapor blasting process. By focusing on factors such as pump material, design, and technology, operators can optimize their equipment's performance, ensuring efficient and effective surface treatment. A focus on quality, backed by expert guidance and support, ensures that the slurry pump remains a reliable workhorse in the vapor blasting arena.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025