Sep . 14, 2024 03:36 Back to list

slurry pump for mining

Slurry Pumps for Mining Essential Equipment for Efficient Operations

In the mining industry, efficient transportation of materials is crucial for productivity and profitability. One of the most vital tools in this regard is the slurry pump. Slurry pumps are specifically designed to handle the complex task of moving thick mixtures of liquid and solids, commonly referred to as slurry. This article explores the significance of slurry pumps in mining operations, their functionality, and the advancements that have been made in their design.

Slurry Pumps for Mining Essential Equipment for Efficient Operations

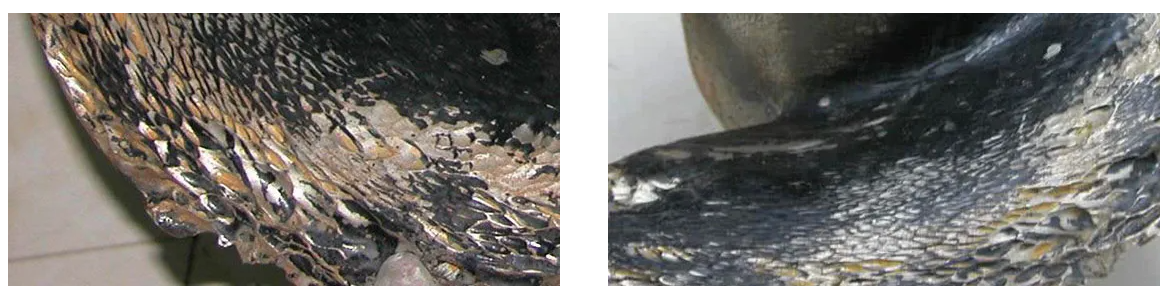

Slurry pumps are engineered to withstand the abrasive nature of the materials they transport. Unlike standard pumps, which may struggle with the wear and tear caused by solid particles, slurry pumps are constructed using robust materials and are designed with specialized components to ensure durability. The most common materials used in the construction of slurry pumps include high-chrome alloys and rubber linings, which enhance longevity and reduce maintenance costs.

slurry pump for mining

The operational principle of a slurry pump is relatively simple yet effective. The pump uses centrifugal force to move the slurry through the system. When the impeller rotates, it creates a low-pressure zone that pulls the slurry into the pump. The centrifugal force then pushes the slurry out through the discharge pipe. This functionality allows for the efficient transport of slurry over various distances, whether it is to transfer materials from the mine to processing facilities or to move tailings to storage areas.

Advancements in technology have significantly improved the performance of slurry pumps. Modern pumps feature enhanced hydraulic designs that maximize efficiency while minimizing energy consumption. Additionally, the advent of wearable sensors and IoT technology has made it possible to monitor pump performance in real-time, allowing operators to detect potential issues before they become significant problems. This predictive maintenance capability not only extends the lifespan of the pumps but also reduces downtime and maintenance costs.

Furthermore, slurry pumps can be customized based on the specific needs of a mining operation. Variables such as slurry density, particle size, and the distance slurry must be transported can all influence the type of pump selected. By tailoring the pump choice to match the unique demands of the mining process, companies can optimize their operations and improve overall efficiency.

In conclusion, slurry pumps are an indispensable component of modern mining operations. Their ability to handle challenging materials and adapt to the specific requirements of different mining processes makes them crucial for efficient resource extraction and processing. As technology continues to advance, slurry pumps will undoubtedly evolve, further enhancing their role in promoting sustainability and efficiency within the mining industry. Investing in high-quality slurry pumps can lead to notable improvements in productivity and ultimately boost the profitability of mining ventures.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025