Nov . 24, 2024 09:22 Back to list

single casing slurry pump factory

Exploring the Significance of Single Casing Slurry Pumps in Industrial Applications

Single casing slurry pumps are crucial components in various industrial applications, particularly in sectors like mining, construction, and waste management. These pumps are designed to handle abrasive materials, making them integral to processes that involve transporting slurries—mixtures of solids and liquids. The efficiency, durability, and reliability of single casing slurry pumps make them a preferred choice for many industries.

Understanding Single Casing Slurry Pumps

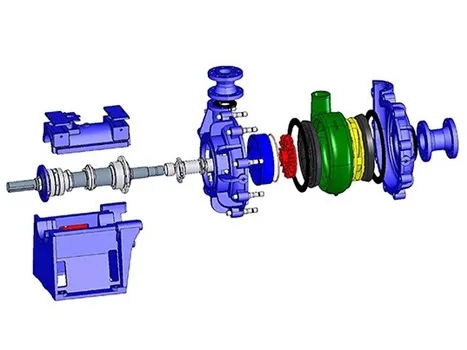

Single casing slurry pumps are characterized by their single-piece design, which houses the impeller and other essential components within one compact unit. This design simplifies the construction and maintenance of the pump, offering several advantages over multi-casing alternatives. The single casing contributes to a more robust structure, which can better withstand the high pressures and abrasive conditions typical in slurry transport.

These pumps typically feature a centrifugal design, allowing them to move slurries with ease. The impeller's rotation generates the necessary flow and pressure, enabling the transfer of materials over long distances or through complex piping systems. The ability to handle solid particles effectively while maintaining a steady flow rate is what sets single casing slurry pumps apart from other types of pumps.

Applications in Various Industries

1. Mining and Mineral Processing Single casing slurry pumps are indispensable in the mining industry, where they are used to transport a mixture of water and minerals from mining sites to processing plants. The durability of these pumps ensures they can handle the harsh conditions and abrasive materials typical in mining operations.

2. Construction In construction, these pumps are employed to manage the removal of mud and slurry generated during excavation and foundation work. Their ability to displace heavy, viscous mixtures makes them vital for maintaining site safety and operational efficiency.

3. Wastewater Management Single casing slurry pumps play a significant role in wastewater treatment plants, where they facilitate the movement of sludge and other solid-liquid mixtures. Their reliability ensures consistent performance in environments where pump failure can lead to significant operational disruptions.

single casing slurry pump factory

4. Dredging Operations In dredging, these pumps are essential for moving sand, silt, and other materials from riverbeds or sea floors. The robust construction of single casing slurry pumps allows them to tackle the challenging conditions found in aquatic environments.

Advantages of Single Casing Slurry Pumps

The single casing design offers several critical advantages

- Lower Maintenance Costs With fewer components and a more straightforward design, single casing pumps often require less maintenance compared to multi-casing options. This translates to lower operational costs and reduced downtime.

- Enhanced Durability The robust construction of single casing pumps allows them to endure abrasive materials and high-pressure conditions, extending their operational life.

- Improved Efficiency The streamlined design promotes better flow rates and higher efficiency, allowing industries to meet their production goals effectively.

Conclusion

In conclusion, single casing slurry pumps are vital assets across multiple industries, providing reliable performance in the transportation of slurries. Their robust design, coupled with ease of maintenance and high efficiency, makes them suitable for handling the rigorous demands of mining, construction, wastewater management, and dredging. As industries continue to evolve and expand, the importance of effective slurry management solutions like single casing slurry pumps cannot be overstated. Investing in these pumps not only ensures operational efficiency but also enhances the overall productivity of industrial processes, paving the way for sustainable growth in challenging environments.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025