Nov . 25, 2024 04:02 Back to list

Rubber Slurry Pump Manufacturing Facilities for Efficient Industrial Solutions

The Importance of Rubber Slurry Pump Factories in Modern Industries

In the world of manufacturing and industrial applications, the efficiency and reliability of equipment play a crucial role in operational success. Among the various types of equipment, slurry pumps are vital for transporting abrasive and corrosive materials in industries such as mining, construction, and wastewater treatment. A specific type of slurry pump, the rubber slurry pump, has gained significant traction due to its unique properties and capabilities. This article explores the significance of rubber slurry pump factories in producing these essential tools and their impact on various industries.

What is a Rubber Slurry Pump?

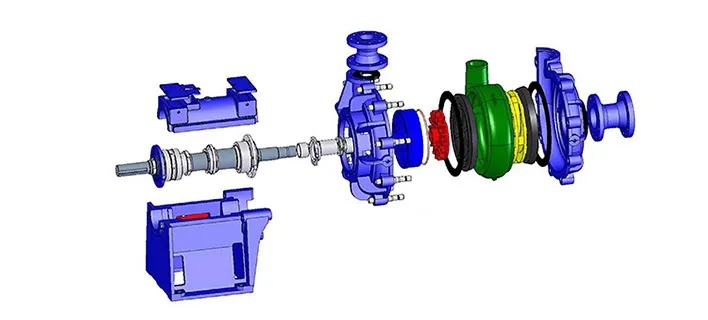

Rubber slurry pumps are specialized pumps designed to handle a wide variety of slurries, which are mixtures of liquids and solid particles. They are particularly useful in applications involving highly abrasive materials, where traditional metal pumps may succumb to rapid wear and tear. The key feature of these pumps is their rubber lining, which provides excellent resistance to abrasion and corrosion. This not only extends the lifespan of the pump but also reduces maintenance costs, making it an attractive option for industries that rely heavily on slurry transport.

Role of Rubber Slurry Pump Factories

Rubber slurry pump factories play a vital role in the production and innovation of these pumps. These manufacturing facilities focus on creating high-quality materials and utilizing advanced engineering techniques to produce pumps that meet the rigorous demands of various applications. The factories employ skilled workers and cutting-edge technologies to ensure that each pump is durable, reliable, and efficient.

One of the primary functions of these factories is the research and development (R&D) of new rubber compounds that enhance the performance of slurry pumps. By experimenting with different formulations, these factories can produce rubber that exhibits superior endurance, flexibility, and resistance to chemicals. This R&D is essential for meeting the evolving needs of industries, particularly as they tackle more complex and abrasive materials.

rubber slurry pump factory

The Impact on Industries

The impact of rubber slurry pump factories extends far beyond manufacturing. The pumps they produce are instrumental in ensuring the smooth operation of several critical industries. In mining, for instance, rubber slurry pumps are used to transport mineral slurries from extraction sites to processing facilities. Their ability to handle abrasive materials significantly reduces downtime and enhances productivity.

In the construction industry, these pumps are essential for managing site runoff and transporting cement slurries. Their efficacy ensures that projects remain on schedule and within budget. Additionally, in wastewater treatment plants, rubber slurry pumps effectively manage the movement of sludge and other byproducts, contributing to the overall efficiency of the treatment process.

Environmental and Economic Benefits

Moreover, the use of rubber slurry pumps has environmental implications. Their durability leads to fewer replacements and less waste, aligning with the principles of sustainable manufacturing. With their efficient operation, they also contribute to energy savings, thus reducing the carbon footprint of various industrial operations. Economically, the initial investment in rubber slurry pumps is often offset by the long-term savings in maintenance and replacement costs.

Conclusion

In summary, rubber slurry pump factories are integral to the production of pumps that are crucial for multiple industries. Their role in developing innovative materials and technologies not only enhances the performance of these pumps but also promotes sustainability and cost-efficiency across industrial applications. As industries continue to evolve and face new challenges, the demand for high-quality rubber slurry pumps will only increase, solidifying the importance of these factories in the modern manufacturing landscape. By ensuring reliable transportation of abrasive materials, rubber slurry pumps supported by robust factories are set to play a significant role in driving industrial progress and efficiency.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025