Jul . 25, 2024 07:35 Back to list

Reliable Supplier for High-Performance 8-6 Rubber Slurry Pumps in China for Optimal Solutions

The Importance of Rubber Slurry Pumps in Modern Industrial Applications

In the realm of industrial processes, the movement of slurries—mixtures of solid particles and liquids—is critical. Industries such as mining, construction, and wastewater treatment require reliable, efficient systems to handle these challenging materials. One such solution is the rubber slurry pump, a device that has gained popularity due to its durability, efficiency, and cost-effectiveness. This article will delve into the significance of rubber slurry pumps, particularly focusing on suppliers in China.

The Functionality of Rubber Slurry Pumps

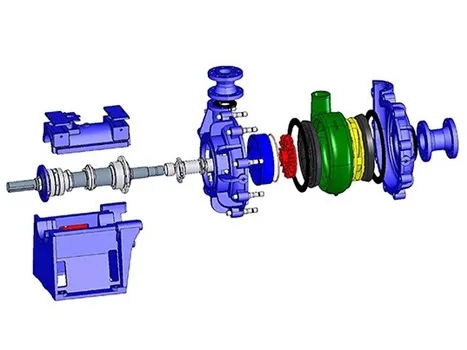

Rubber slurry pumps are designed to handle abrasive materials, making them ideal for transporting slurries that contain a high concentration of solid particles. These pumps utilize rubber-lined components to protect against wear and tear caused by the abrasive nature of the slurries. The rubber lining offers an exceptional lifespan compared to traditional metal pumps, reducing the frequency of maintenance and replacement.

These pumps function by using rotational energy to move the slurry from one place to another. The ability to handle high solids content while maintaining flow efficiency is a crucial factor for industries that rely on consistent operations. The design of rubber slurry pumps allows them to operate effectively under high pressures, making them indispensable in various applications.

Advantages of Rubber Slurry Pumps

1. Durability and Longevity The rubber materials used in these pumps are highly resistant to abrasion and corrosion. This not only extends the life of the pump but also ensures consistent performance over time.

2. Cost-Effective Although the initial investment may be higher than other pump types, the lifespan and reduced maintenance costs of rubber slurry pumps lead to lower overall operational expenses.

china 8-6 rubber slurry pump supplier

3. Versatility Rubber slurry pumps can be used in a wide range of industries, from mining where they transport minerals, to water treatment plants where they handle sludge.

4. Ease of Maintenance Many rubber slurry pumps are designed for straightforward maintenance. Their modular construction allows for easy disassembly and replacement of worn parts, reducing downtime.

The Role of Chinese Suppliers

China has emerged as a leading supplier of rubber slurry pumps, thanks to its robust manufacturing capabilities and competitive pricing. Numerous companies in China specialize in the production of these pumps, ensuring a wide range of models to meet different operational needs. Suppliers offer various options, including custom designs tailored to specific applications.

Chinese manufacturers take pride in their technological advancements and commitment to quality control. Many of them adhere to international standards, ensuring that their products can compete on a global scale. Moreover, with the rising demand for eco-friendly manufacturing processes, many suppliers are now focusing on sustainable production methods, which not only benefit the environment but also appeal to eco-conscious consumers.

Conclusion

Rubber slurry pumps are essential to modern industrial operations, especially in sectors that require the efficient transport of abrasive and dense materials. The advantages of these pumps, including their durability, cost-effectiveness, and versatility, make them an optimal choice for a variety of applications. As suppliers in China continue to innovate and meet the global demand, it is evident that rubber slurry pumps will play a crucial role in the future of industrial operations across the globe. By understanding the benefits of these pumps and the competitive landscape of Chinese suppliers, companies can make informed decisions that enhance their operational efficiency and sustainability.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025