Feb . 13, 2025 08:58 Back to list

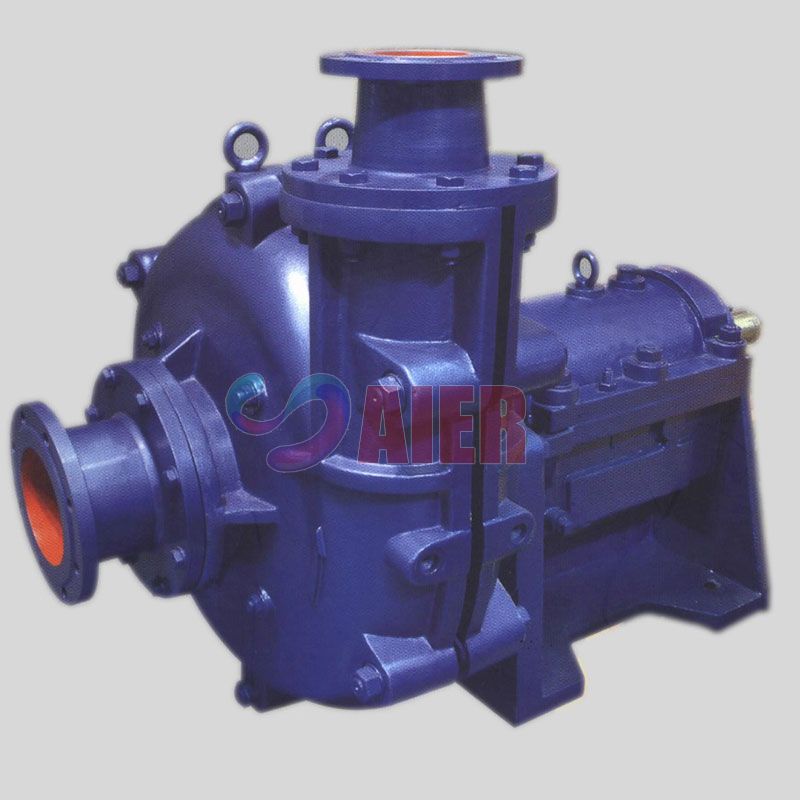

recessed impeller slurry pump

Navigating the realm of industrial machinery, the recessed impeller slurry pump emerges as a notable innovation, revered for its superior efficiency in handling abrasive and viscous slurries. This pump type has garnered significant interest across industries, from mining to wastewater treatment, owing to its unique design and operation principles.

In terms of expertise, understanding the nuances of these pumps can significantly influence operational outcomes. Professionals handling these machines should be well-versed in selecting the appropriate size and type for their specific application needs. This involves calculating slurry density, viscosity, and the size of solid particles expected in the fluid. Adhering to these parameters ensures that the pump not only meets but exceeds operational expectations. Those venturing into the market for recessed impeller slurry pumps will find a diverse array of options tailored for specific industrial needs. Partnering with reputable manufacturers and suppliers ensures access to cutting-edge technology and the latest advancements in pump design. Additionally, leveraging expert training programs and technical support can maximize the performance and reliability of these systems. Trust in recessed impeller slurry pumps stems from a well-documented history of success across various industrial applications. Case studies and testimonials from satisfied operators underscore these pumps' ability to deliver consistent, reliable, and efficient performance even in the most challenging environments. This track record, combined with rigorous industry standards and certifications, further enhances their credibility and appeal. In conclusion, the recessed impeller slurry pump stands as a testament to engineering ingenuity and practical problem-solving in fluid management. Its design and functionality address key industry pain points, offering solutions that are both innovative and effective. As industries continue to evolve and demand more efficient and durable equipment, these pumps will likely remain at the forefront, providing exemplary performance that businesses can rely on.

In terms of expertise, understanding the nuances of these pumps can significantly influence operational outcomes. Professionals handling these machines should be well-versed in selecting the appropriate size and type for their specific application needs. This involves calculating slurry density, viscosity, and the size of solid particles expected in the fluid. Adhering to these parameters ensures that the pump not only meets but exceeds operational expectations. Those venturing into the market for recessed impeller slurry pumps will find a diverse array of options tailored for specific industrial needs. Partnering with reputable manufacturers and suppliers ensures access to cutting-edge technology and the latest advancements in pump design. Additionally, leveraging expert training programs and technical support can maximize the performance and reliability of these systems. Trust in recessed impeller slurry pumps stems from a well-documented history of success across various industrial applications. Case studies and testimonials from satisfied operators underscore these pumps' ability to deliver consistent, reliable, and efficient performance even in the most challenging environments. This track record, combined with rigorous industry standards and certifications, further enhances their credibility and appeal. In conclusion, the recessed impeller slurry pump stands as a testament to engineering ingenuity and practical problem-solving in fluid management. Its design and functionality address key industry pain points, offering solutions that are both innovative and effective. As industries continue to evolve and demand more efficient and durable equipment, these pumps will likely remain at the forefront, providing exemplary performance that businesses can rely on.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025