Jan . 14, 2025 15:49 Back to list

OEM Castings

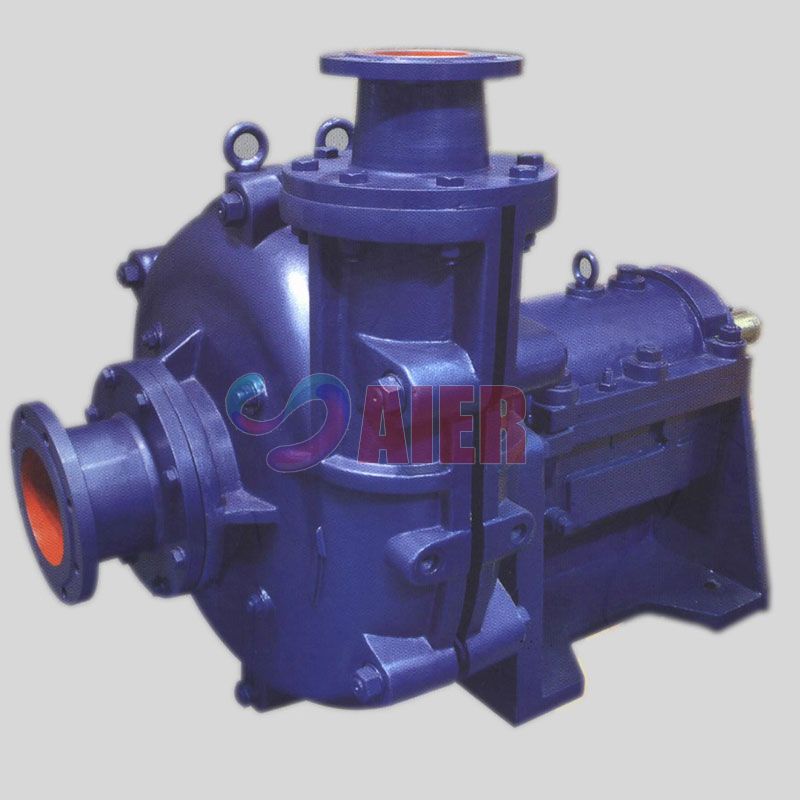

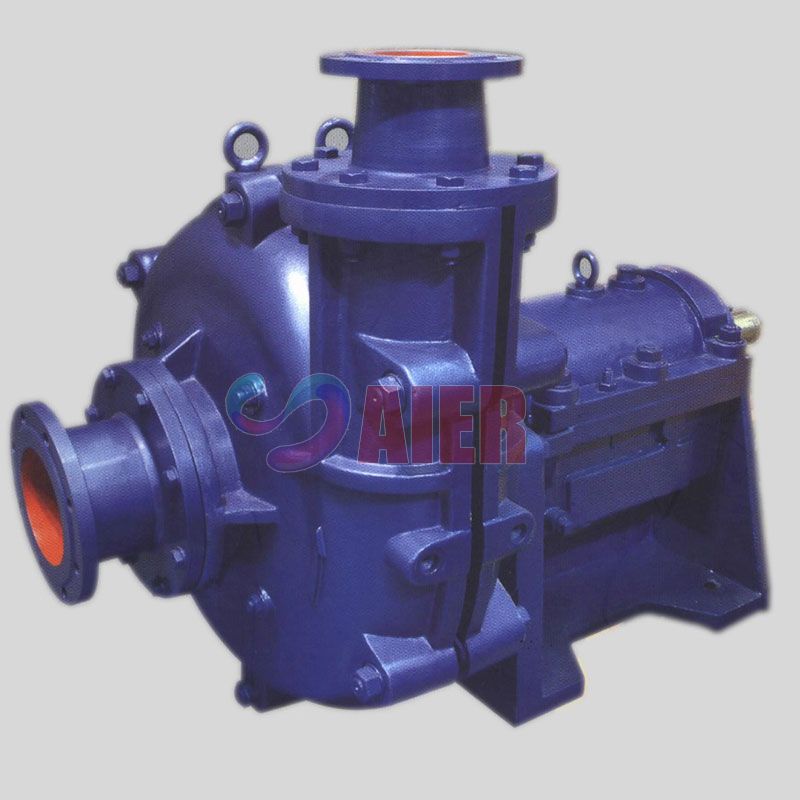

OEM heavy duty slurry pumps represent a cornerstone in industries where handling abrasive slurries is crucial. These pumps are engineered to meet the demands of industries such as mining, construction, and dredging, where they are integral in transporting a mixture of solid particles and fluids in a cost-effective and efficient manner. Their robust design and adaptability to various applications make them indispensable.

Choosing the right OEM heavy duty slurry pump is a decision that involves assessing specific operational needs. Factors to consider include the type of slurry being handled, the required flow rate, and the total head needed for the operation. Consulting with experts who have a deep understanding of the intricacies of these pumps can provide invaluable insights and recommendations, ensuring that the chosen pump will deliver optimal performance and longevity. Investing in quality OEM heavy duty slurry pumps not only addresses immediate operational needs but also contributes to long-term infrastructure improvement. Operational efficiency gained through reduced energy consumption and minimized wear translates to savings and environmental benefits. Moreover, the confidence in a reliable pump system enhances productivity and safety across operations. In conclusion, OEM heavy duty slurry pumps offer a blend of robust engineering, versatility, and reliability that meets the demands of challenging industrial environments. With a focus on cutting-edge technology, sustainable materials, and a commitment to quality, these pumps not only provide solutions for today's industry challenges but also set the standard for future innovations. Trust in their capacity to perform under pressure, backed by expertise and a track record of success, ensures that they remain a vital component in industrial operations worldwide.

Choosing the right OEM heavy duty slurry pump is a decision that involves assessing specific operational needs. Factors to consider include the type of slurry being handled, the required flow rate, and the total head needed for the operation. Consulting with experts who have a deep understanding of the intricacies of these pumps can provide invaluable insights and recommendations, ensuring that the chosen pump will deliver optimal performance and longevity. Investing in quality OEM heavy duty slurry pumps not only addresses immediate operational needs but also contributes to long-term infrastructure improvement. Operational efficiency gained through reduced energy consumption and minimized wear translates to savings and environmental benefits. Moreover, the confidence in a reliable pump system enhances productivity and safety across operations. In conclusion, OEM heavy duty slurry pumps offer a blend of robust engineering, versatility, and reliability that meets the demands of challenging industrial environments. With a focus on cutting-edge technology, sustainable materials, and a commitment to quality, these pumps not only provide solutions for today's industry challenges but also set the standard for future innovations. Trust in their capacity to perform under pressure, backed by expertise and a track record of success, ensures that they remain a vital component in industrial operations worldwide.

Next:

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025