Dec . 04, 2024 16:07 Back to list

oem 4x3dd slurry pump manufacturer

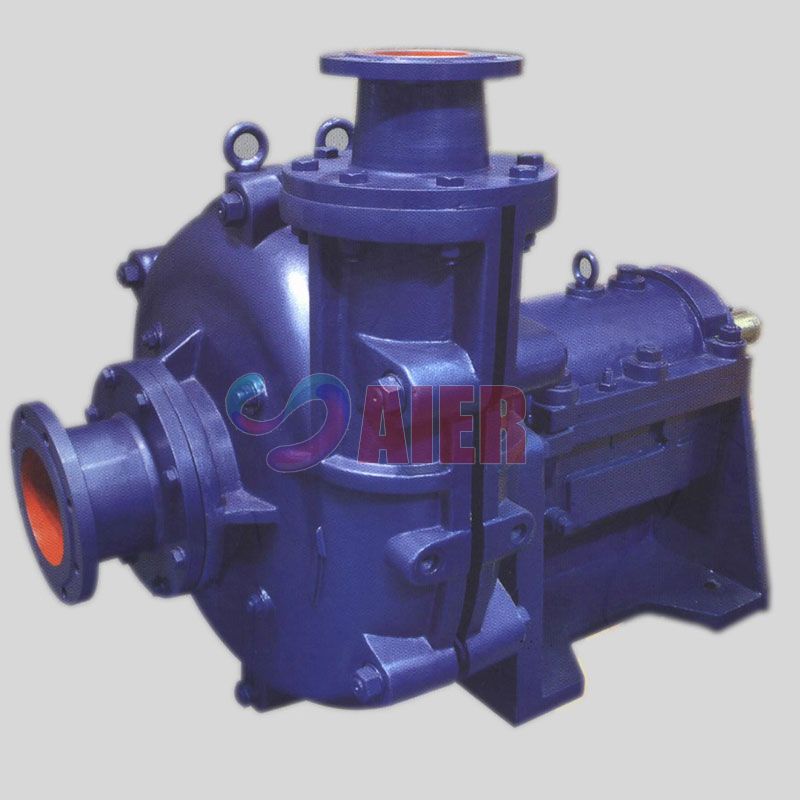

Introduction to OEM 4x3DD Slurry Pump Manufacturer

In the realm of industrial pump manufacturing, the OEM 4x3DD slurry pump stands out as a significant tool for various applications. Recognized for its durability, efficiency, and reliability, this type of pump is crucial for handling abrasive and viscous materials in industries such as mining, construction, and waste management. Understanding the features, benefits, and manufacturing processes of the OEM 4x3DD slurry pump can provide valuable insights into its pivotal role in modern industrial operations.

Design and Features

The OEM 4x3DD slurry pump is designed specifically for the efficient transfer of slurries, which are mixtures of solid particles and liquids. Key features of this pump include a robust construction that ensures longevity and minimizes wear and tear. It is typically made from high-chrome alloy castings, which provide remarkable resistance to abrasion and erosion—common issues faced by pumps handling harsh materials.

The pump's design also features a large inlet and outlet size, allowing it to handle substantial volumes of slurry while minimizing the risk of blockages. Additionally, the OEM 4x3DD slurry pump is equipped with a unique impeller and volute configuration that optimizes hydraulic performance. This design promotes a smooth flow of slurry, effectively reducing the energy consumption typically required for pumping dense materials.

Applications of the OEM 4x3DD Slurry Pump

The versatility of the OEM 4x3DD slurry pump makes it suitable for a diverse range of applications

. In the mining sector, it is commonly used for transporting ores, tailings, and other mineral slurries. The pump’s ability to handle high solids concentration without significant performance degradation makes it particularly valuable in this industry.In construction, particularly in dewatering operations, the OEM 4x3DD slurry pump is essential for managing mud and other fluids. Moreover, in wastewater treatment facilities, these pumps are employed to transport sludge and other byproducts of the treatment process. Across these sectors, the efficiency and reliability of the OEM 4x3DD slurry pump ensure smooth operations, reducing downtime and maintenance costs.

oem 4x3dd slurry pump manufacturer

The Manufacturing Process

The manufacturing of the OEM 4x3DD slurry pump involves several critical steps to ensure quality and performance. The process begins with the selection of high-quality raw materials, which are integral to the performance and durability of the pump. Manufacturers typically employ state-of-the-art technologies in casting and machining components, ensuring precision and consistency.

Quality control is a vital aspect throughout the manufacturing process. Each pump undergoes rigorous testing to confirm that it meets industry standards and performance expectations. This includes assessments of flow rates, pressure, and resistance to wear and tear. By adhering to stringent quality assurance protocols, manufacturers can guarantee that their products deliver reliability and efficiency in real-world applications.

Benefits of Choosing OEM 4x3DD Slurry Pumps

Opting for an OEM 4x3DD slurry pump can yield numerous benefits for businesses. First and foremost, the durability of these pumps leads to reduced operational costs over time. The high resistance to wear means less frequent replacements and repairs, translating to significant savings for companies.

Furthermore, the energy efficiency of the OEM 4x3DD slurry pump results in lower energy costs, contributing to a more sustainable operation. By using a pump that optimizes flow and minimizes back pressure, organizations can reduce their overall carbon footprint while maintaining productivity.

Conclusion

In conclusion, the OEM 4x3DD slurry pump represents a vital asset for industries dealing with abrasive and viscous materials. Through its robust design, versatile applications, and a meticulous manufacturing process, it provides enduring reliability and efficiency. Companies looking to enhance their operational performance should consider investing in OEM 4x3DD slurry pumps, benefiting from reduced operational costs, increased efficiency, and improved sustainability in their processes. As industries continue to evolve, the role of such specialized equipment will undoubtedly become even more significant in meeting the demands of modern production and environmental standards.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025