Sep . 03, 2024 14:57 Back to list

mini slurry pump factory

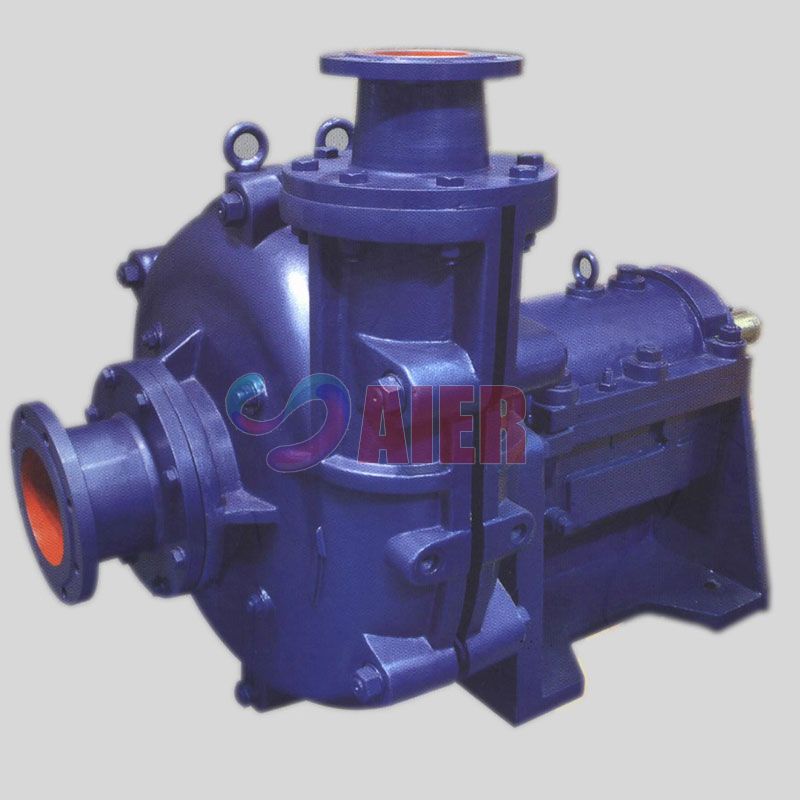

Mini Slurry Pump Factory Innovation in Fluid Handling Solutions

In the realm of industrial equipment, mini slurry pumps have emerged as vital components in the transportation of abrasive and viscous materials. These small yet powerful pumps are specifically designed to handle slurry, a mixture of liquids and solids, making them essential in sectors such as mining, construction, and wastewater management. A mini slurry pump factory plays a crucial role in the manufacturing and innovation of these essential devices.

The operation of a mini slurry pump factory is centered around the integration of advanced engineering, technology, and quality control

. Each pump is crafted to withstand the challenges posed by abrasive materials, ensuring reliable performance in demanding environments. The factory utilizes state-of-the-art manufacturing techniques, employing high-quality materials that enhance durability and efficiency.One of the primary objectives of a mini slurry pump factory is to cater to diverse industry needs. Customization is a key aspect, as different applications require pumps with varying capacities and configurations. Factories often collaborate with clients to design pumps that meet specific requirements, including size, material compatibility, and flow rates. This bespoke approach not only enhances customer satisfaction but also establishes long-term partnerships in the industry.

mini slurry pump factory

Moreover, factories focus on continuous innovation to keep up with the evolving demands of fluid handling. Research and development teams within these facilities work tirelessly to improve existing designs and introduce new technologies. Implementation of automation in the manufacturing process enhances precision and reduces production times. Additionally, newer materials and coatings are being explored to increase the lifespan of pumps and minimize maintenance costs.

Quality assurance is another cornerstone of mini slurry pump production. Rigorous testing procedures are conducted to ensure that each pump meets industry standards and customer expectations. These tests often include assessments of hydraulic performance, wear resistance, and operational reliability. By maintaining stringent quality control measures, factories can deliver products that guarantee optimal performance under various conditions.

In conclusion, a mini slurry pump factory represents a hub of innovation and excellence in fluid handling solutions. By combining advanced manufacturing processes, custom design capabilities, and stringent quality control, these factories are not only meeting the demands of today’s industries but are also paving the way for the future of pumping technology. As industries continue to evolve, the importance of efficient, reliable slurry pumps will only increase, positioning mini slurry pump factories at the forefront of industrial advancement.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025