Sep . 28, 2024 08:48 Back to list

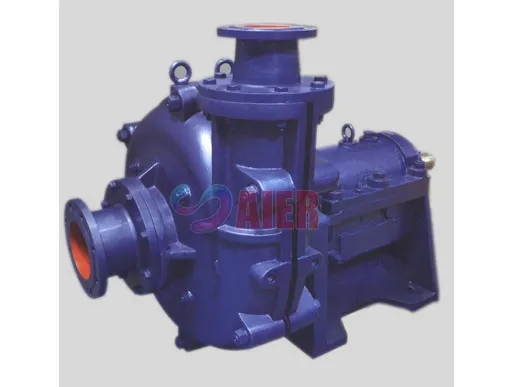

Durable Slurry Pump Solutions for Efficient Metal Handling and Transport

Understanding Metal Slurry Pumps A Comprehensive Overview

Metal slurry pumps play a crucial role in various industries, particularly in mining, mineral processing, and construction. These specialized pumps are designed to handle a mixture of solid particles and liquids, referred to as slurry. The efficiency and reliability of metal slurry pumps are vital for maintaining productivity and ensuring the smooth operation of processes that involve the transportation of abrasive and viscous materials.

What is a Metal Slurry Pump?

A metal slurry pump is a type of centrifugal pump specifically engineered to move slurries composed of solids and liquids. Unlike standard pumps, which may struggle or even fail when dealing with abrasive slurries, metal slurry pumps are constructed using robust materials designed to withstand erosion and corrosion. The key components typically include a pump casing, an impeller, and a shaft, all made from high-strength metals to enhance durability.

Key Features and Benefits

1. Durability and Resistance The primary advantage of metal slurry pumps is their resistance to wear and tear. They are constructed from materials such as high-chrome alloys, stainless steel, or other resistant metals that can withstand the harsh environments where slurries are processed. This durability ensures a longer service life, reducing maintenance costs and downtime.

2. High Efficiency Metal slurry pumps are designed to handle high flow rates and deliver efficient performance. Their impellers are shaped and engineered to reduce turbulence and deliver a steady flow, which is critical in processes where consistency matters. An efficient pump can significantly enhance production rates, making it a cost-effective solution over time.

3. Versatility These pumps can manage a wide range of slurry types, including those found in mining, wastewater treatment, and construction. Their ability to adapt to various viscosities and solid contents allows industries to streamline operations and improve overall effectiveness.

4. Customizability Many manufacturers offer customization options to ensure that the slurry pump meets specific application requirements. This includes adjustments to dimensions, materials, and even the design of the impeller or casing to optimize performance for particular slurries.

Applications in Various Industries

metal slurry pump

Metal slurry pumps are employed in numerous industries, each utilizing them for distinct purposes

- Mining In the mining sector, slurry pumps are used to transport ores, coal, and tailings. They efficiently move highly abrasive and viscous materials, which are byproducts of extraction processes.

- Mineral Processing These pumps enable the transportation of mineral slurries during beneficiation and processing. They play a critical role in separating valuable minerals from ores.

- Wastewater Management In wastewater treatment facilities, metal slurry pumps help manage and transport sludge and other particulate matter, ensuring effective and efficient processing of sewage and industrial waste.

- Construction Construction projects often involve the use of cemented slurries or mixtures. Metal slurry pumps are essential for transferring these materials from one location to another, particularly in large-scale projects.

Challenges and Considerations

While metal slurry pumps offer many advantages, they are not without challenges. Abrasive materials can lead to significant wear over time, necessitating regular maintenance and, in some cases, replacement of parts such as the impeller or casing. Additionally, operators must ensure that pumps are properly selected and installed to handle specific slurry characteristics effectively. Incorrect sizing or misapplication can lead to inefficiencies and increased wear.

Conclusion

Metal slurry pumps are essential components in various industries, providing durability and efficiency in the transport of abrasive, solid-liquid mixtures. Their ability to resist wear and handle a wide range of applications makes them invaluable in sectors like mining, mineral processing, and construction. When properly maintained and selected for the right application, these pumps can lead to significant operational benefits, enhancing productivity while minimizing costs. As industries continue to evolve and face new challenges, metal slurry pumps will undoubtedly play a critical role in the advancement of process technologies.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025