Nov . 11, 2024 03:37 Back to list

Interchangeable Components for Slurry Pump Manufacturing Facilities and Spare Parts Solutions

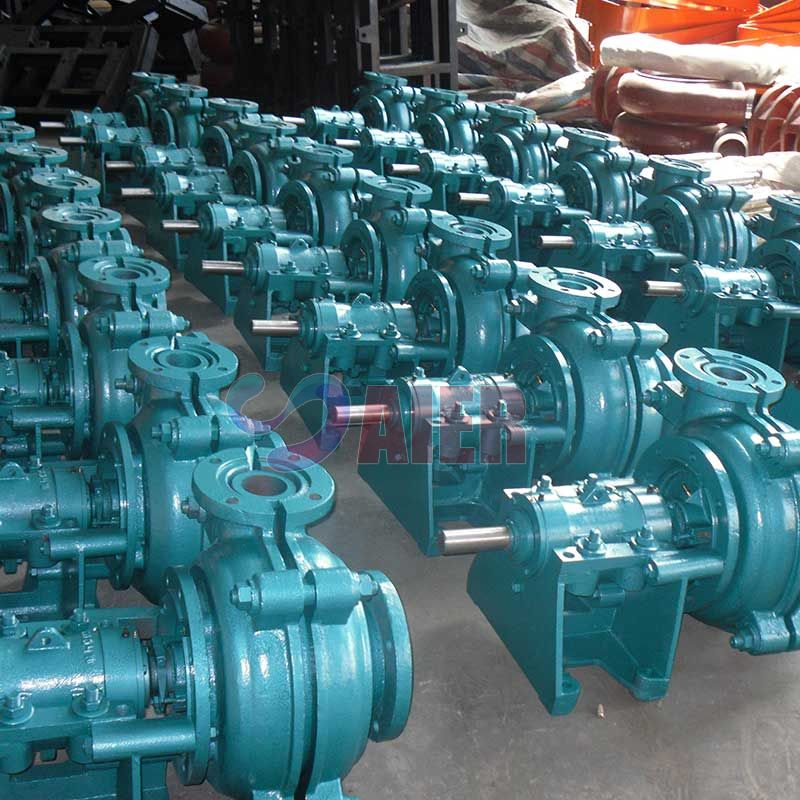

Interchangeable Spare Parts of Slurry Pump Factories Ensuring Efficiency and Sustainability in Industrial Applications

In an era where efficiency and sustainability are paramount, the importance of interchangeable spare parts in slurry pump factories cannot be overstated. Slurry pumps play a critical role in various industries, including mining, construction, and wastewater management, where they are responsible for transporting abrasive and corrosive slurries. Given the harsh operating conditions these pumps endure, the availability of high-quality spare parts is essential for maintaining optimal performance and minimizing downtime.

Interchangeable spare parts are components that can be substituted for one another without any modification to the equipment. This concept is particularly beneficial in the context of slurry pumps, as it allows for greater flexibility in repairs and maintenance. When a specific part fails, operators can quickly replace it with an equivalent part from another manufacturer or even a generic supplier. This adaptability not only reduces lead times for repairs but also helps in managing inventory more effectively.

One of the primary advantages of using interchangeable spare parts in slurry pump factories is the reduction in operational costs. When a pump breaks down, the resulting downtime can lead to significant financial losses. However, by utilizing interchangeable parts, factories can ensure that they have access to the necessary components without waiting for specialized parts to be manufactured or shipped. This accessibility is particularly vital in remote or less-developed areas where supply chains may be less reliable.

Moreover, interchangeable parts contribute to improved sustainability practices within the industry. By allowing repairs to be executed with readily available components, factories can extend the life of their equipment and reduce waste. Instead of discarding an entire pump due to a single faulty part, operators can replace that part and continue utilizing the pump. This not only conserves resources but also diminishes the environmental impact associated with manufacturing new equipment.

interchangeable spare parts of slurry pump factories

However, the benefits of interchangeable spare parts go beyond operational efficiencies and sustainability. It also fosters a competitive market, encouraging manufacturers to produce high-quality components that meet strict compatibility standards. As more companies recognize the value of interchangeable spare parts, they strive to innovate and improve their products to ensure they remain a viable option for slurry pump repairs.

In the context of global supply chain challenges, especially highlighted during the COVID-19 pandemic, the ability to rely on interchangeable parts has proven beneficial. Companies can diversify their supplier bases and mitigate risks associated with dependency on a single manufacturer. This resilience allows industries to maintain productivity even during times of crisis.

To further enhance the adoption of interchangeable spare parts, investment in training is essential. Operators and maintenance personnel must be well-versed in identifying compatible components and understanding the intricacies of different pump models. Providing adequate education can empower employees to make informed decisions and execute repairs efficiently, ensuring that operations remain smooth and effective.

The growing trend towards the digitalization of industries also plays a crucial role in the future of interchangeable spare parts. With advancements in technology, companies can implement predictive maintenance strategies that leverage data analytics to foretell potential equipment failures. By proactively addressing issues before they lead to breakdowns, factories can minimize their dependency on spare parts and reduce their overall inventory needs.

In conclusion, the interchangeable spare parts of slurry pump factories represent a significant advancement in industrial operations. They not only enhance efficiency and reduce costs but also promote sustainable practices and improve resilience within supply chains. Investing in interchangeable components and the training necessary for their effective use is a strategic decision that can yield long-term benefits for companies within the slurry pump sector. As industries continue to evolve, embracing the concept of interchangeability will undoubtedly play a crucial role in driving operational success and sustainability in the years to come.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025