Dec . 12, 2024 18:31 Back to list

industrial vertical sump pump

Understanding Industrial Vertical Sump Pumps

In the realm of industrial fluid management, vertical sump pumps play a critical role in efficiently removing water and other liquids from a variety of applications. These pumps are specifically designed for handling wastewater, stormwater, or other fluids in sumps, pits, or reservoirs. They can operate in submerged conditions, which makes them ideal for businesses that deal with heavy fluid collections.

What is a Vertical Sump Pump?

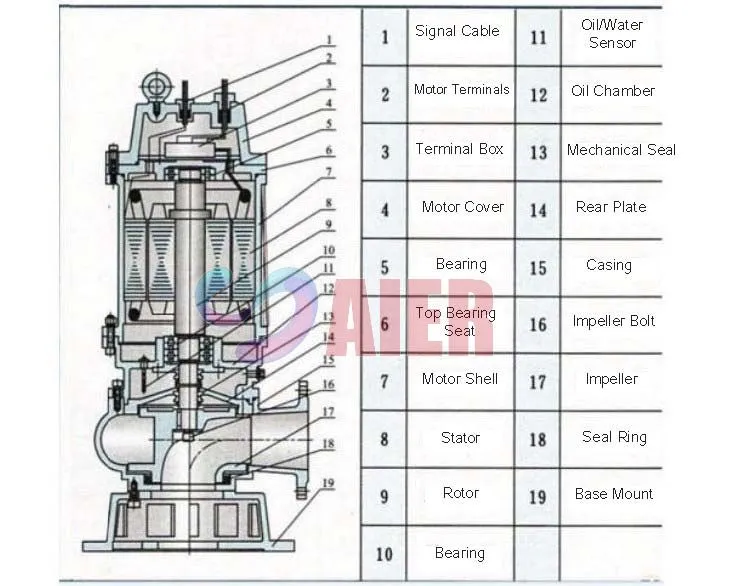

A vertical sump pump is characterized by its vertical design and is typically mounted above the fluid level. The pump features a long shaft that extends down into the sump, with an impeller at the lower end that draws the fluid upward and out of the sump. This design allows the pump to operate in deeper settings while effectively preventing air locks that can hinder performance.

The construction of vertical sump pumps is robust, often featuring materials resistant to corrosion and wear, such as stainless steel, cast iron, and various polymers. This strength ensures they can handle abrasive and corrosive liquids often found in industrial settings. Their adaptability makes them suitable for various applications, including mining operations, chemical processing plants, and wastewater treatment facilities.

Key Advantages

1. Space Efficiency Since vertical sump pumps operate in a vertical orientation, they save valuable floor space, making them particularly beneficial in environments where space is at a premium.

2. Ease of Maintenance The design of vertical sump pumps allows for straightforward maintenance. Many models provide access to the mechanical components without the need for entire disassembly or removing the pump from the sump, thus minimizing downtime.

3. Versatility These pumps are highly versatile and can handle a wide range of fluids, including clean water, dirty water, and aggressive chemicals. This versatility makes them invaluable in industries where different fluids require efficient removal.

4. High Efficiency Vertical sump pumps can operate at high efficiencies, providing significant energy savings over time. With advancements in motor technology and hydraulic design, modern sump pumps utilize less energy while delivering optimal performance.

Applications

Vertical sump pumps are widely used across various industrial sectors

industrial vertical sump pump

- Wastewater Management In treatment plants, these pumps help remove wastewater from collection basins and work to maintain efficient processing of sewage and stormwater.

- Mining Operations Here, they are essential for dewatering mining pits and tunnels, allowing for safe and efficient extraction of minerals.

- Chemical Processing In facilities that deal with chemicals, vertical sump pumps manage the movement of hazardous materials, ensuring safe removal from containment areas

.- Construction For construction sites where groundwater can accumulate, these pumps are crucial in keeping the sites dry, ensuring a safe working environment.

Choosing the Right Vertical Sump Pump

Selecting the appropriate vertical sump pump for a specific application involves several considerations

1. Fluid Type Understand the properties of the liquids being pumped, including their viscosity, chemical composition, and whether they contain solids. This will determine the materials needed for the pump.

2. Flow rate and Head Requirements Calculate the required flow rate and the total dynamic head (TDH) to ensure the pump can meet operational demands.

3. Installation Environment Assess the specific environment where the pump will be installed, including temperature, potential for corrosion, and accessibility for maintenance.

4. Energy Efficiency Consider pumps with energy-efficient designs and motors, which can lead to reduced operating costs over time.

Conclusion

In summary, industrial vertical sump pumps are integral to managing fluid in various settings. Their space-efficient design, ease of maintenance, and remarkable versatility make them a go-to solution for industries dealing with large volumes of liquid. By understanding the applications, advantages, and selection criteria for these pumps, businesses can optimize their fluid management processes and enhance operational efficiency. Investing in the right vertical sump pump can lead not only to improved safety and reliability but also long-term cost savings.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025