Oct . 22, 2024 03:30 Back to list

impeller slurry pump suppliers

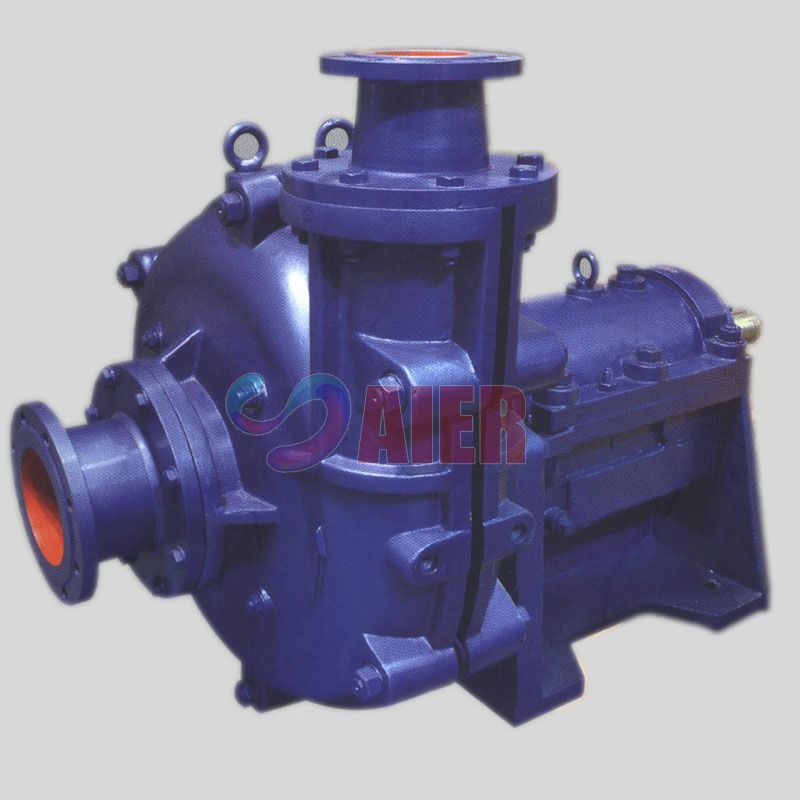

Understanding Impeller Slurry Pumps and Their Suppliers

Impeller slurry pumps are critical components in various industrial applications, especially within mining, construction, and sewage management sectors. These pumps are specifically designed to transport abrasive, viscous, and corrosive materials that are often found in slurry form. An efficient impeller design is essential for maintaining high performance and ensuring the longevity of the pump.

The Importance of Impeller Design

The impeller of a slurry pump plays a crucial role in determining its efficiency and effectiveness. An optimal impeller design allows for better fluid dynamics, minimizes wear and tear, and enhances the pump’s overall hydraulic performance. Impeller shapes, sizes, and materials are tailored to meet specific operational requirements, ensuring that the pump can handle various types of slurries, including those containing solid particles.

Selecting Reliable Suppliers

When it comes to procuring impeller slurry pumps, choosing the right suppliers is vital. Reputable suppliers offer not only high-quality products but also essential services, including installation, maintenance, and support. Factors to consider when selecting suppliers include

1. Product Range It’s important to choose a supplier that offers a wide variety of models and configurations to meet different industrial needs. This variety allows companies to select pumps that perfectly fit their operational requirements.

impeller slurry pump suppliers

2. Quality Assurance Suppliers should adhere to international quality standards and offer warranties on their products. High-quality pumps lead to lower maintenance costs and increased operational efficiency.

3. Customer Support Reliable suppliers typically provide robust customer support services, including training for personnel on how to operate and maintain the pumps effectively. This support can be crucial in avoiding operational downtime.

4. Experience and Reputation Suppliers with extensive industry experience often possess valuable insights into the challenges faced by their clients. Their established reputation can be a strong indicator of their reliability and service quality.

Market Trends and Innovations

In recent years, the slurry pump market has seen several innovations aimed at improving efficiency and reducing costs. Advanced materials, such as high-chrome alloys and rubber linings, enhance the durability of the pumps against wear from abrasive slurries. Moreover, technology integration, such as smart sensors for monitoring performance, helps to optimize pump operations and prevent failures.

Conclusion

The role of impeller slurry pumps in industrial applications cannot be overstated. They are essential for transporting challenging materials effectively. When selecting suppliers, it is crucial to consider their product range, quality assurance, customer support, and industry reputation. As the market continues to evolve with technological advancements, so too will the capabilities of slurry pumps, paving the way for more efficient and sustainable industrial processes. Making informed decisions regarding suppliers and equipment can lead to significant operational benefits, ultimately contributing to a company's success in its respective field.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025