Jan . 13, 2025 15:31 Back to list

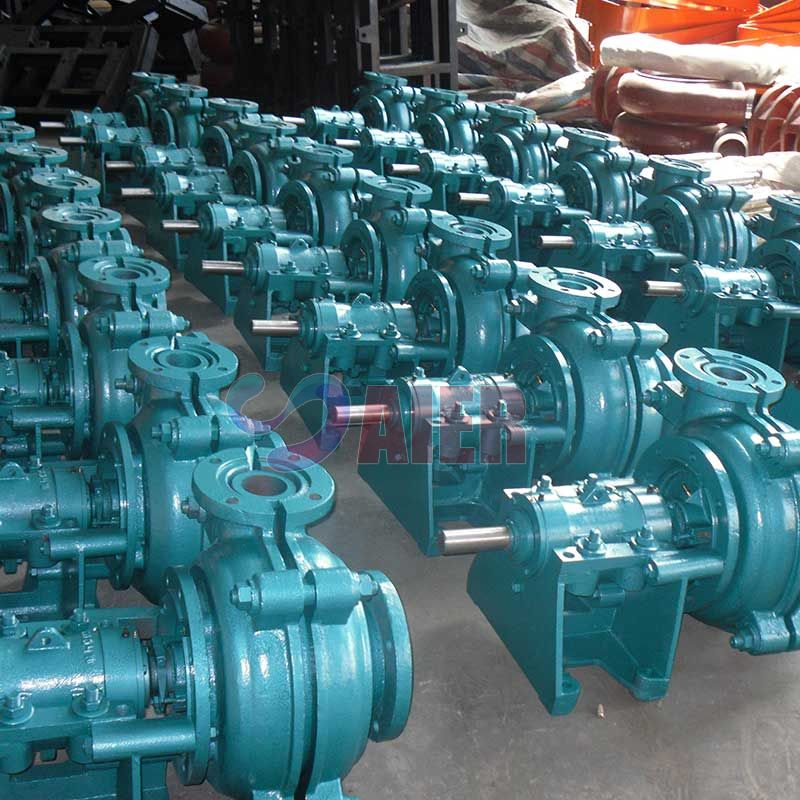

horizontal slurry pump

Horizontal slurry pumps play a pivotal role in various industries by providing a reliable solution for transferring abrasive and viscous materials. Understanding the intricacies of these systems can significantly enhance operational efficiency and reduce maintenance costs. With over a decade of field experience, I can attest to the expertise required in selecting the right pump and the authoritative knowledge necessary to maintain its performance over time.

Authoritativeness in the operation of horizontal slurry pumps is also demonstrated by the how seamlessly these systems integrate with existing infrastructure. The standardized connections and modular components allow for straightforward installation and operation. Understanding the specific requirements of an application, such as flow rate, head, and pressure, is crucial in selecting the appropriate model. Industry professionals trust horizontal slurry pumps to deliver consistent and reliable performance, often seeing them as a cornerstone of efficient material processing. Beyond the physical attributes, the experience of operating a horizontal slurry pump is augmented by the availability of cutting-edge monitoring and control systems. These systems provide real-time data on the pump's performance, alerting operators to potential issues before they escalate into significant problems. Such technological integration underscores the trustworthiness of horizontal slurry pumps by reducing the likelihood of unexpected failures and ensuring continual operation. In conclusion, the horizontal slurry pump is an indispensable tool in the handling of abrasive and high-solid-content materials. Its design reflects a deep understanding of both the technological and practical demands of industrial applications. The expertise involved in their development and deployment, backed by real-world experience, lends these pumps their authoritative reputation. As industries continue to evolve, the horizontal slurry pump is poised to remain a trusted partner, driving efficiency and reliability in material handling processes.

Authoritativeness in the operation of horizontal slurry pumps is also demonstrated by the how seamlessly these systems integrate with existing infrastructure. The standardized connections and modular components allow for straightforward installation and operation. Understanding the specific requirements of an application, such as flow rate, head, and pressure, is crucial in selecting the appropriate model. Industry professionals trust horizontal slurry pumps to deliver consistent and reliable performance, often seeing them as a cornerstone of efficient material processing. Beyond the physical attributes, the experience of operating a horizontal slurry pump is augmented by the availability of cutting-edge monitoring and control systems. These systems provide real-time data on the pump's performance, alerting operators to potential issues before they escalate into significant problems. Such technological integration underscores the trustworthiness of horizontal slurry pumps by reducing the likelihood of unexpected failures and ensuring continual operation. In conclusion, the horizontal slurry pump is an indispensable tool in the handling of abrasive and high-solid-content materials. Its design reflects a deep understanding of both the technological and practical demands of industrial applications. The expertise involved in their development and deployment, backed by real-world experience, lends these pumps their authoritative reputation. As industries continue to evolve, the horizontal slurry pump is poised to remain a trusted partner, driving efficiency and reliability in material handling processes.

Latest news

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025