Oct . 16, 2024 01:15 Back to list

Efficient Horizontal Froth Pumps for Enhanced Fluid Management and Transfer Solutions

Horizontal Froth Pump An Essential Solution for Challenging Applications

In various industrial sectors, the transportation of slurries, especially those containing frothy materials like minerals and chemicals, presents significant challenges. The horizontal froth pump has emerged as a vital piece of equipment, specifically designed to handle such demanding applications efficiently. This article delves into the construction, working principles, advantages, and applications of horizontal froth pumps, highlighting their importance in modern industry.

Understanding Horizontal Froth Pumps

A horizontal froth pump is a type of centrifugal pump engineered to manage frothy slurries. These pumps differ from conventional pumps due to their unique design, which allows them to handle the volume of gas bubbles typically present in frothy materials. The primary function of a horizontal froth pump is to transport these slurries without significant damage or loss of efficiency.

Construction and Working Principles

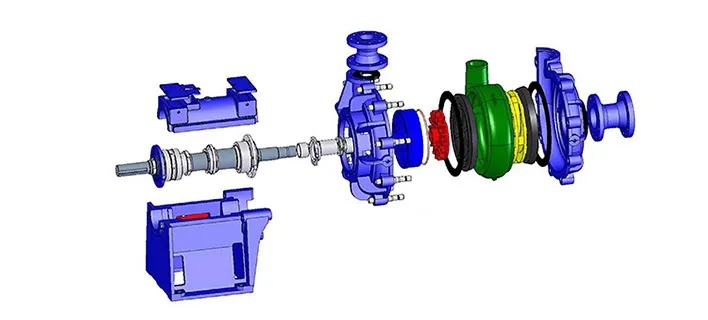

Horizontal froth pumps are designed with several key components that enhance their performance

1. Impeller The impeller is a crucial component of the pump that imparts kinetic energy to the slurry. In froth pumps, the impeller is designed with specific geometries to minimize the amount of air trapped within the slurry, ensuring efficient transport.

2. Volute Chamber The volute chamber surrounds the impeller and helps in converting kinetic energy into pressure energy. It is carefully designed to facilitate the smooth flow of frothy liquids.

3. Suction and Discharge Ports These ports are strategically placed to ensure optimal flow of the frothy slurry into and out of the pump.

When operating, a horizontal froth pump draws in the frothy slurry through the suction port. The impeller rotates, imparting energy to the mixture, which then exits through the discharge port. The design enables the pump to handle the froth without allowing excessive air to accumulate, which would otherwise reduce efficiency.

Advantages of Horizontal Froth Pumps

horizontal froth pump

1. Effective Handling of Frothy Slurries Horizontal froth pumps are specifically tailored to manage the unique challenges posed by frothy materials, making them more efficient than standard pumps in handling these applications.

2. Reduced Maintenance Costs Due to their robust construction and efficient design, horizontal froth pumps generally require less maintenance, leading to lower operational costs over time.

3. Versatility These pumps can handle a wide range of materials, including heavy minerals, waste material, and even certain types of chemicals, making them suitable for various industries such as mining, chemical processing, and wastewater treatment.

4. High Efficiency With a well-designed impeller and volute setup, horizontal froth pumps can maintain a high level of efficiency, even when dealing with the complexities of frothy slurries.

Applications in Industry

Horizontal froth pumps are extensively used in several fields

- Mining and Mineral Processing In this sector, they are vital for transporting slurries from flotation cells, where minerals are separated from the ore. The ability to handle a mixture of liquid and air is crucial during this process.

- Wastewater Treatment These pumps are employed to transport sludge and frothy by-products within treatment facilities, ensuring that systems remain operational and efficient.

- Chemical Manufacturing In chemical processing, froth pumps can transfer slurries containing various additives and reaction by-products safely and effectively.

Conclusion

In conclusion, horizontal froth pumps play a pivotal role in industries where the transportation of frothy slurries is a necessity. Their unique design, combined with high efficiency and versatility, makes them an indispensable tool for handling challenging materials. As industries continue to evolve and face new challenges, the significance of horizontal froth pumps in ensuring smooth operations will only grow, cementing their place in modern manufacturing and processing environments.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025