Nov . 10, 2024 10:33 Back to list

Premium Warman Slurry Pump Design Blueprints from Leading Manufacturer

High-Quality Warman Slurry Pump Drawings Factory An Overview

In the world of industrial machinery, slurry pumps play a crucial role in transporting abrasive and viscous materials across various sectors such as mining, mineral processing, and wastewater treatment. Among the leading manufacturers of these pumps is the Warman brand, renowned for its durability and efficiency. At the heart of producing high-quality Warman slurry pumps are specialized factories that focus on innovative design, engineering, and precision manufacturing.

Understanding the Slurry Pump

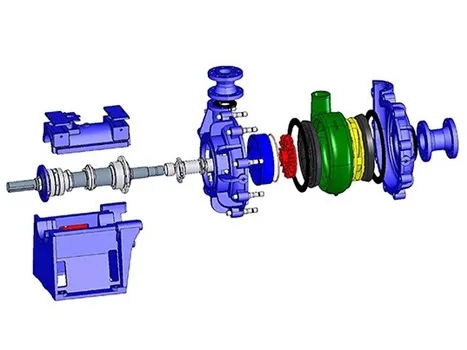

Slurry pumps are designed to handle mixtures of liquid and solid particles, which can be particularly challenging due to the wear and tear these materials can cause. Warman slurry pumps are engineered to withstand harsh conditions, making them suitable for heavy-duty applications. Their design typically includes a robust casing, high-chrome alloy impellers, and wear-resistant liners, ensuring that they maintain performance even under excessive physical stress.

The Importance of Quality Drawings

The production of Warman slurry pumps starts with detailed engineering drawings. These drawings are vital as they provide the specifications and dimensions needed to manufacture each component accurately. Quality drawings ensure that every element of the pump— from the impeller to the casing— fits perfectly and functions effectively. A reputable Warman slurry pump drawings factory will employ advanced CAD (Computer-Aided Design) software to create precise and detailed designs. This technology allows for the simulation of various operational scenarios, enabling engineers to optimize the pump's performance before manufacturing begins.

Manufacturing Processes

Once the drawings are finalized, the manufacturing process can commence. Factories specializing in Warman slurry pumps use sophisticated machinery and techniques to produce each component. This includes CNC (Computer Numerical Control) machining, which provides high precision and repeatability in parts production. The use of high-quality materials is crucial, as the components must resist abrasion and corrosion over time. As such, the factory will often source premium-grade alloys and materials that meet stringent industry standards.

high quality warman slurry pump drawings factory

Quality Control

Quality assurance is an integral part of the manufacturing process in a Warman slurry pump drawings factory. Each stage of production undergoes rigorous quality control measures to ensure that the final product meets specific performance and safety standards. Testing can include operational trials and wear testing to simulate real-world usage and assess the durability of the pumps. The commitment to quality ensures that customers receive reliable products that can operate efficiently in demanding applications.

Customization and Innovation

A key advantage of a specialized Warman slurry pump factory is the ability to provide customized solutions. Different applications require different specifications, and many consumers seek tailored products that meet their unique needs. Whether it’s modifying the design of an impeller or adjusting the pump's size, a capable factory will offer customization options to enhance performance.

Moreover, continuous innovation is vital in the slurry pump industry. Factories often collaborate with research institutions and industry experts to incorporate the latest technologies and materials into their designs. This commitment to innovation not only improves the efficiency of the pumps but also helps in reducing operational costs for end-users.

Conclusion

In summary, high-quality Warman slurry pump drawings factories play an essential role in serving industries that rely on robust and efficient slurry handling solutions. From meticulous design processes to precision manufacturing and stringent quality control, these factories ensure that every Warman slurry pump is built to last and perform under challenging conditions. By investing in high-quality materials and innovative practices, they support various sectors in overcoming the challenges associated with transporting abrasive and thick slurries effectively. Whether you require standard pumps or customized solutions, a reputable Warman slurry pump factory is key to achieving operational excellence.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025