Oct . 22, 2024 00:30 Back to list

Top Manufacturer of High-Quality Horizontal Slurry Pumps for Reliable Performance

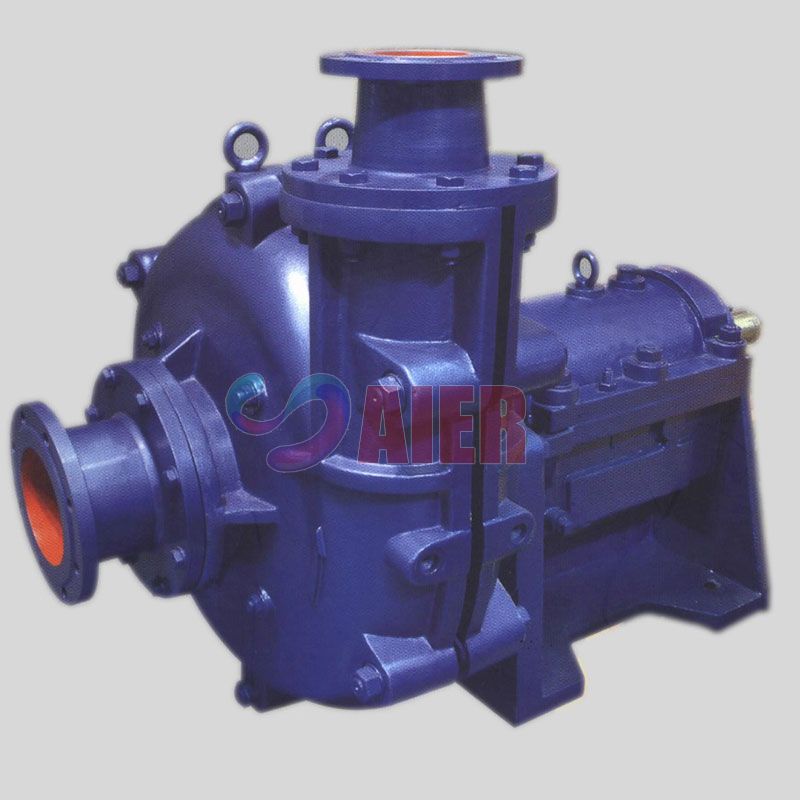

High-Quality Warman Horizontal Slurry Pump Manufacturer

In the world of industrial pumping solutions, slurry pumps play a vital role in transporting abrasive and viscous materials. Among the most recognized brands in this sector is Warman, known for its high-quality horizontal slurry pumps. For businesses seeking reliable and efficient pumping solutions, partnering with a reputable Warman horizontal slurry pump manufacturer is essential. This article explores the features and benefits of these pumps and guides on selecting the right manufacturer for your needs.

What Are Warman Horizontal Slurry Pumps?

Warman horizontal slurry pumps are engineered to handle tough applications commonly found in mining, mineral processing, dredging, and various industrial sectors. These pumps are designed to transport slurries that contain solid particles of varying sizes and densities, making them ideal for conveying materials such as ores, coal, and wastewater. The horizontal configuration allows for easier maintenance and operation, providing a robust solution for challenging environments.

One of the key features of Warman slurry pumps is their high wear resistance, thanks to the use of advanced materials such as chrome iron and rubber linings. This durability extends the life of the pump and minimizes the need for frequent replacements, ultimately resulting in cost savings for operators.

The Advantages of Choosing Warman Horizontal Slurry Pumps

1. Robust Design Warman pumps are constructed to withstand extreme conditions, including high pressures and abrasive materials. The engineering behind these pumps ensures they operate effectively in demanding environments without compromising performance.

2. Energy Efficiency With advancements in pumping technology, Warman horizontal slurry pumps are designed to be energy-efficient. This efficiency not only reduces operation costs but also helps companies meet their sustainability goals.

3. Versatility Warman pumps are suitable for a wide range of applications, from transporting thick slurries in mining to processing wastewater in industrial settings. This versatility makes them an ideal choice for businesses requiring reliable pumping solutions across various operations.

4. Low Maintenance The ease of maintenance inherent in Warman horizontal slurry pumps is another significant advantage. The open design facilitates quick access to critical components, allowing for faster repairs and less downtime.

high quality warman horizontal slurry pump manufacturer

5. Custom Solutions Many Warman manufacturers offer customized pump solutions to meet specific customer requirements. This allows businesses to obtain a pump tailored to their unique operational demands, enhancing efficiency and effectiveness.

Selecting a High-Quality Warman Horizontal Slurry Pump Manufacturer

When choosing a manufacturer for Warman horizontal slurry pumps, consider the following factors

1. Industry Experience Look for manufacturers with extensive experience in producing slurry pumps. A company with a proven track record is more likely to deliver reliable and durable products.

2. Compliance and Certifications Ensure that the manufacturer adheres to industry standards and possesses relevant certifications. Compliance indicates a commitment to quality and safety in the manufacturing process.

3. Customer Support A reputable manufacturer should offer robust customer support, including technical assistance and warranties. This support is crucial for troubleshooting and ensuring the longevity of the pumps.

4. Reputation Research the manufacturer’s reputation in the market. Customer testimonials, case studies, and industry awards can provide insights into the reliability and performance of their products.

5. Innovation The best manufacturers invest in research and development to create innovative solutions that enhance pump efficiency and functionality. Look for companies that continually strive to improve their products.

In conclusion, Warman horizontal slurry pumps are a cornerstone of effective material transport in various industrial sectors. By selecting a high-quality manufacturer, businesses can ensure they are equipped with reliable, efficient, and durable pumping solutions that contribute to their success. Investing in the right slurry pump technology can lead to significant operational benefits, ultimately driving productivity and profitability in the long run.

-

Top China Submersible Slurry Pump Supplier Durable & Efficient Solutions

NewsMay.17,2025

-

Submersible Pump Spares Manufacturer High-Quality & Durable Components

NewsMay.17,2025

-

Vertical Centrifugal Sump Pump Supplier China Factory Solutions

NewsMay.16,2025

-

Vertical Spindle Slurry Pump Suppliers High-Quality China Manufacturers

NewsMay.16,2025

-

High-Quality Casting Submersible Pump Parts Manufacturer Durable Solutions

NewsMay.16,2025

-

Vertical Sump & Mud Screw Slurry Pump Company Durable Solutions

NewsMay.15,2025