Oct . 18, 2024 12:03 Back to list

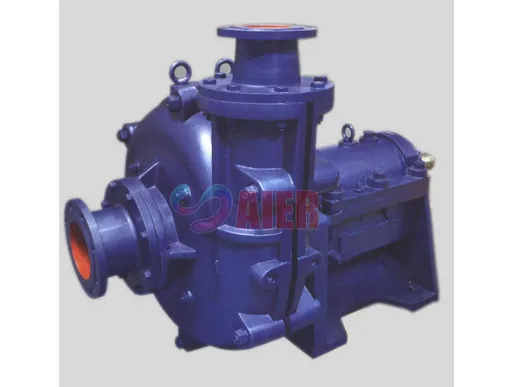

Top Manufacturers of Durable High-Quality Thick Slurry Pumps for Heavy-Duty Applications

The Importance of High-Quality Thick Slurry Pumps in Industrial Applications

In the world of industrial processes, the efficient handling of slurries—mixtures of solids and liquids—is essential for maintaining productivity and ensuring the integrity of systems. Among the critical equipment used in these applications are thick slurry pumps, designed specifically to transport dense and abrasive mixtures with minimal wear and maximum efficiency. Choosing the right manufacturer for high-quality thick slurry pumps can significantly impact operational efficiency, safety, and overall costs.

Understanding Thick Slurry Pumps

Thick slurry pumps are engineered to handle viscous liquids laden with solid particles, including sand, coal, minerals, and various by-products from manufacturing processes. These pumps are characterized by their robust construction and specialized design features that allow them to effectively manage challenging materials. The nature of slurry—often abrasive and corrosive—means that the pumps must exhibit durability and reliability under high-stress conditions.

Key Features of High-Quality Slurry Pumps

1. Durable Materials The best slurry pumps are constructed from high-grade materials such as high chromium alloys, rubber linings, or even ceramic coatings, which provide resistance against wear and corrosion. This is especially crucial when dealing with abrasive slurries that can erode equipment over time.

2. Robust Design Quality manufacturers invest in research and development to create pump designs that mitigate the risk of clogs and blockages. Features such as large wear components, adjustable impellers, and effective sealing systems help ensure that the pump can operate efficiently even under demanding conditions.

3. Customizability Every industrial application has unique requirements. Leading manufacturers offer customizable solutions tailored to specific operational needs, including variations in sizes, capacities, and materials. This ability to customize can make a significant difference in the efficiency and effectiveness of slurry handling.

4. Energy Efficiency Advanced slurry pump designs incorporate energy-efficient technologies, which not only reduce operational costs but also minimize environmental impact. Such pumps can optimize fluid dynamics and fluid transfer, leading to reduced energy consumption over time.

high quality thick slurry pump manufacturers

5. Ease of Maintenance High-quality slurry pumps are designed with maintenance in mind. Features such as quick access to wear parts and modular designs facilitate easier maintenance and reduce downtime, significantly impacting productivity.

Selecting the Right Manufacturer

Choosing the right manufacturer of thick slurry pumps is crucial for ensuring long-term operational success. Here are some factors to consider

- Reputation and Experience Look for manufacturers with a proven track record in the industry. Established companies often have extensive experience in producing reliable pumps and can provide valuable insights into the best solutions for specific applications.

- Quality Certifications Opt for manufacturers that adhere to international quality standards, such as ISO certifications. This ensures that the products meet stringent quality and safety benchmarks.

- Customer Support and Service A manufacturer’s commitment to customer support is essential. This includes technical assistance during installation, access to spare parts, and responsive service teams to address any issues promptly.

- Reviews and Case Studies Research customer feedback and case studies to gauge the performance of the manufacturer’s products in real-world applications. Satisfied customers often provide insights into the reliability and efficiency of the equipment.

Conclusion

In conclusion, high-quality thick slurry pumps are indispensable in various industries, from mining and mineral processing to wastewater treatment and chemical manufacturing. Selecting the right manufacturer is critical to ensuring that these pumps perform optimally and provide long-lasting service. By focusing on durability, customizability, energy efficiency, and ease of maintenance, industries can enhance their operations and safeguard their investments. As technology evolves and industries advance, the demand for high-quality slurry pumps will continue to rise, cementing their place as a cornerstone of effective fluid management in industrial applications.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025