Nov . 30, 2024 10:08 Back to list

high quality submersible slurry pump price supplier

High Quality Submersible Slurry Pump A Comprehensive Guide to Pricing and Suppliers

Submersible slurry pumps are essential tools in various industries, particularly in mining, construction, and waste management. These pumps are designed to handle abrasive and viscous fluids, making them ideal for transporting slurry—a mixture of solids and liquid. Given their crucial role, the quality and price of submersible slurry pumps are critical factors for businesses that rely on these devices.

Understanding Submersible Slurry Pumps

Submersible slurry pumps operate by being submerged in the fluid they are designed to pump. This unique design allows them to function efficiently while eliminating the need for a suction line, making them ideal for deep pits or watery environments. They can handle a variety of slurries, including those with high solid content, which are typically challenging to pump with traditional pumps.

Key Features to Consider

When selecting a high-quality submersible slurry pump, several features must be considered. These include

1. Material Construction Pumps made from durable materials, such as hard metal or high-quality polyurethane, offer longevity and better performance in abrasive environments.

2. Motor Power The motor's power rating directly influences the pump's efficiency and ability to handle different densities of slurry.

3. Pump Design The design of the pump, including the impeller and casing, affects its pumping capability. Submersible pumps with a heavy-duty impeller design can manage larger solids effectively.

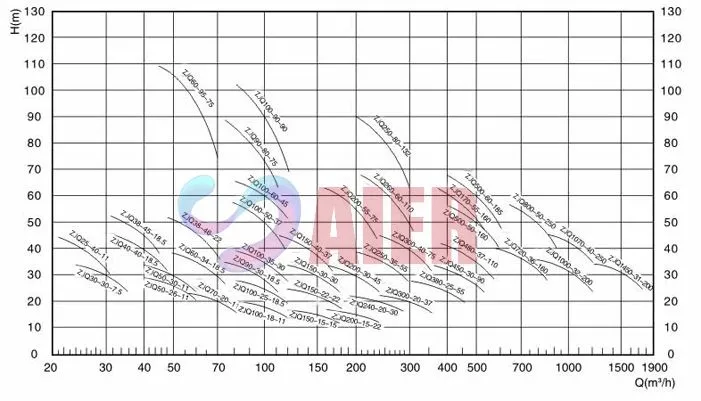

4. Flow Rate and Head It’s crucial to select a pump that matches the required flow rate and head—this ensures efficiency and avoids overworking the pump, which can lead to premature failure.

Factors Affecting Price

The price of a high-quality submersible slurry pump can vary widely due to several factors

1. Brand Reputation Established brands may command a higher price due to their proven reliability and performance, while lesser-known brands may offer lower prices but could potentially compromise quality.

high quality submersible slurry pump price supplier

2. Pump Specifications Advanced features, such as variable speed control and stainless steel components, often increase the cost of the pump.

3. Application Requirements Pumps designed for specialized applications tend to be more expensive due to their engineering and manufacturing processes.

4. Market Demand Like many industries, supply and demand greatly affects pricing. In peak construction seasons, prices may rise due to increased demand.

5. Warranty and After-Sales Service Pumps that come with extended warranties and reliable after-sales support often feature higher pricing, reflecting the additional value offered.

Finding Reliable Suppliers

When searching for a supplier of high-quality submersible slurry pumps, consider the following steps

1. Research Conduct thorough research on potential suppliers. Look for testimonials and reviews from other customers to gauge reliability and product performance.

2. Comparative Pricing Obtain quotes from multiple suppliers to compare prices. Pay attention not only to the initial cost but also to quality and warranty terms.

3. Service and Support Evaluate the level of customer service and technical support each supplier offers. A supplier that provides extensive support can save you time and money in the long run.

4. After-Sales Support Inquire about maintenance services and the availability of spare parts. A strong after-sales support system can greatly enhance the longevity and performance of the pump.

5. Certification and Compliance Ensure that the suppliers comply with industry standards and regulations. Certifications can be a good indicator of a supplier’s commitment to quality.

Conclusion

Investing in a high-quality submersible slurry pump is essential for efficiency and operational success in any industry that deals with slurry. By understanding the key features, factors influencing price, and how to find reliable suppliers, businesses can make informed decisions that lead to long-term benefits. Remember that while cost is important, it’s just as crucial to prioritize quality to avoid costly downtime caused by equipment failure. As you navigate your purchasing journey, always weigh cost against performance and reliability to secure the best possible product for your needs.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025