Feb . 18, 2025 08:00 Back to list

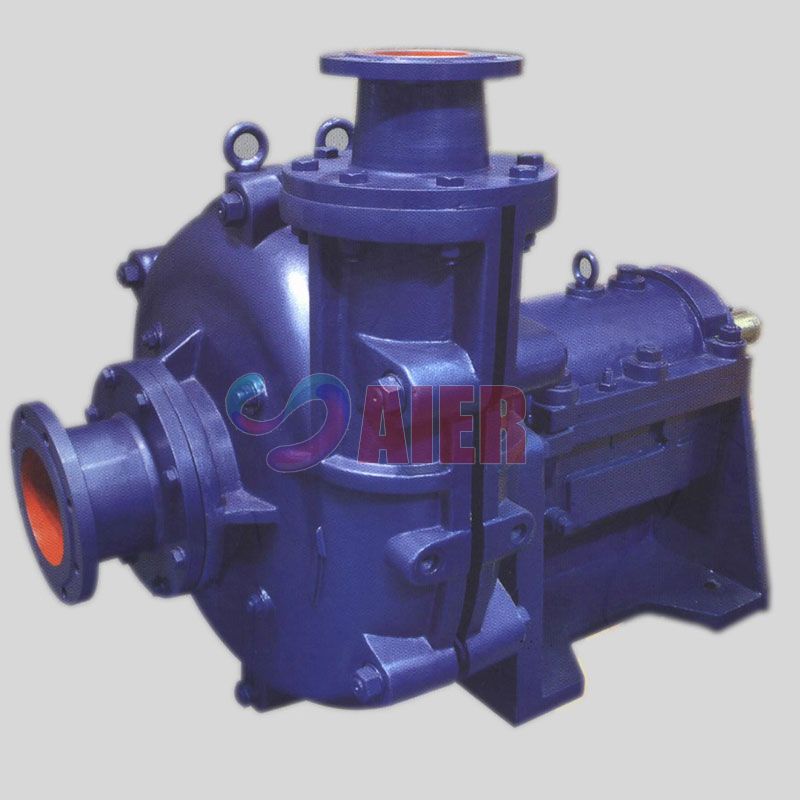

high quality chemical centrifugal slurry pump

Expertise, efficiency, and effectiveness are paramount when selecting the right centrifugal slurry pump. For businesses handling arduous processes that involve moving mixtures of water and finely pulverized solids, a high-quality small centrifugal slurry pump redirects focus, redefining workflow success and operational excellence.

This commitment to excellence is reflected in energy efficiency—an area where small centrifugal slurry pumps excel. Their design decreases energy consumption rates, achieving higher hydraulic efficiencies through smooth flow passages and precision-engineered components. Reduced energy usage lowers operational costs significantly and aligns with global sustainability objectives, which is a top priority for responsible corporations today. Furthermore, operational experience reveals that ease of maintenance is pivotal in pump selection. The modular architecture of these pumps allows straightforward part replacement, meaning less downtime and reduced service costs. Plant operators often highlight user-friendly features like manual comprehensive guides and digital interfaces for real-time monitoring and diagnostics—empowering them to make informed decisions and take timely actions without waiting for external technical support. When insights from practical experiences come into play, nuanced factors like vibrational behavior, noise levels, and operational flexibility become integral criteria. High-quality pumps minimize vibrations, which helps maintain stable operational conditions and eliminates the risk of equipment failure. Silent operation ensures compliance with environmental noise regulations and enhances workplace conditions, improving overall productivity. In sum, the high-quality small centrifugal slurry pump exemplifies a synthesis of engineering excellence, operational economy, and environmental stewardship. It stands as a testament to advanced technological implementation tailored to meet specific industry needs and customer requirements. By choosing pumps that embody these qualities, industries gain more than just a machine; they secure a sophisticated tool built on trust, expertise, and authority—paving the way toward sustainable growth and operational success.

This commitment to excellence is reflected in energy efficiency—an area where small centrifugal slurry pumps excel. Their design decreases energy consumption rates, achieving higher hydraulic efficiencies through smooth flow passages and precision-engineered components. Reduced energy usage lowers operational costs significantly and aligns with global sustainability objectives, which is a top priority for responsible corporations today. Furthermore, operational experience reveals that ease of maintenance is pivotal in pump selection. The modular architecture of these pumps allows straightforward part replacement, meaning less downtime and reduced service costs. Plant operators often highlight user-friendly features like manual comprehensive guides and digital interfaces for real-time monitoring and diagnostics—empowering them to make informed decisions and take timely actions without waiting for external technical support. When insights from practical experiences come into play, nuanced factors like vibrational behavior, noise levels, and operational flexibility become integral criteria. High-quality pumps minimize vibrations, which helps maintain stable operational conditions and eliminates the risk of equipment failure. Silent operation ensures compliance with environmental noise regulations and enhances workplace conditions, improving overall productivity. In sum, the high-quality small centrifugal slurry pump exemplifies a synthesis of engineering excellence, operational economy, and environmental stewardship. It stands as a testament to advanced technological implementation tailored to meet specific industry needs and customer requirements. By choosing pumps that embody these qualities, industries gain more than just a machine; they secure a sophisticated tool built on trust, expertise, and authority—paving the way toward sustainable growth and operational success.

Latest news

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025