Nov . 09, 2024 20:14 Back to list

Top Quality Slurry Submersible Pump Manufacturer for Reliable Performance and Efficiency

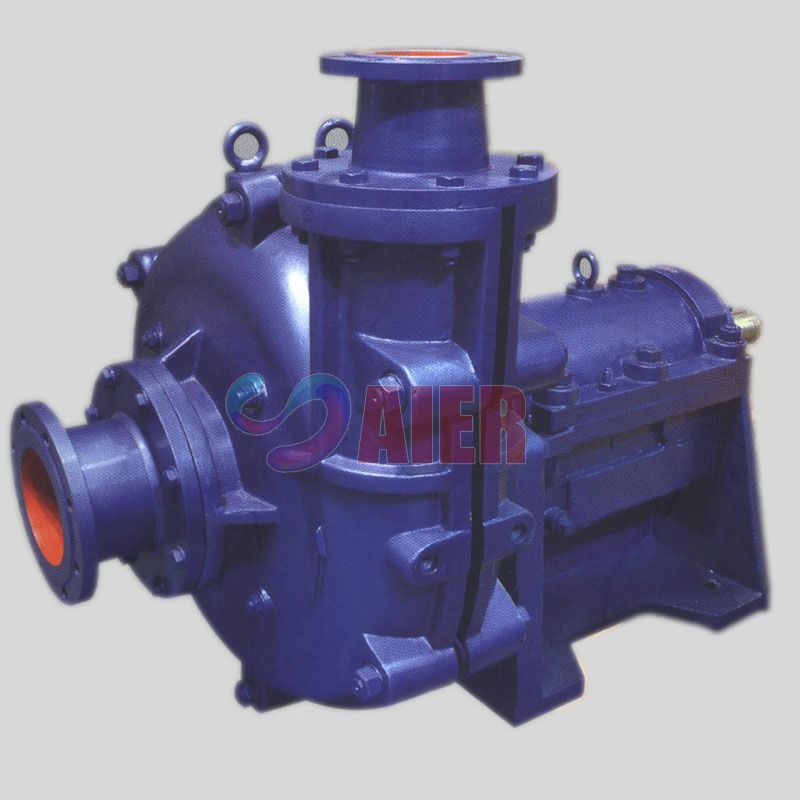

High-Quality Slurry Submersible Pump Factory A Comprehensive Overview

In the world of industrial machinery, slurry submersible pumps play a pivotal role in various sectors, including mining, construction, and wastewater management. These specialized pumps are designed to handle abrasive and viscous fluids, making them essential for transporting slurry mixtures that contain solids. A high-quality slurry submersible pump factory is crucial for producing reliable and efficient pumps that meet the demands of diverse applications. This article explores the key features, manufacturing processes, and advantages of high-quality slurry submersible pumps.

Understanding Slurry Submersible Pumps

Slurry submersible pumps are unique in their construction and functionality. Unlike standard pumps, these units are submerged in the slurry, which allows them to operate efficiently in environments where traditional pumps would fail. They are engineered to handle heavy solids and sludges, making them ideal for mining operations, dredging projects, and wastewater treatment facilities. The design typically includes a robust impeller and casing made from high-grade materials that resist wear and corrosion.

Manufacturing Processes in a High-Quality Factory

A factory dedicated to manufacturing high-quality slurry submersible pumps employs advanced technology and strict quality control measures. The manufacturing process begins with the selection of premium raw materials, which are crucial for the durability and efficiency of the pumps. High-quality steel alloys, rubber compounds, and specialty coatings are commonly used to ensure the pumps can withstand harsh operating conditions.

1. Precision Engineering Advanced CNC machines play a significant role in achieving precise dimensions and tolerances in pump components. This precision engineering is vital for maintaining performance and longevity.

2. Casting and Forging Many components, such as impellers and housings, are produced through casting or forging processes, which enhance their strength and resistance to wear.

3. Assembly Skilled technicians assemble the components with meticulous attention to detail, ensuring that each pump meets the company's high standards. They check for proper alignment and fit to minimize the risk of operational failures.

high quality slurry submersible pump factory

4. Quality Testing After assembly, pumps undergo rigorous testing procedures, including performance tests, pressure tests, and flow tests. These tests help identify any defects and confirm that the pumps function as designed under various conditions.

Advantages of High-Quality Slurry Submersible Pumps

Investing in high-quality slurry submersible pumps offers numerous advantages. Here are some key benefits that make them a preferred choice in the industry

1. Enhanced Durability High-quality materials and advanced engineering techniques result in pumps that can withstand abrasive and corrosive environments. This durability reduces the frequency of repairs and replacements, leading to lower operational costs.

2. Improved Efficiency Efficient hydraulic designs allow for optimal energy use, ensuring that the pumps operate effectively even in challenging conditions. This efficiency not only saves energy costs but also enhances overall productivity.

3. Reliability The rigorous quality control processes in high-quality factories ensure that pumps are reliable and dependable. Operators can trust these pumps to perform consistently, reducing downtime and maintenance needs.

4. Custom Solutions Many high-quality slurry submersible pump factories offer customization options. This capability enables customers to select pumps tailored to their specific requirements, ensuring that they get the ideal solution for their applications.

Conclusion

A high-quality slurry submersible pump factory plays an essential role in producing pumps that are critical to various industries. By focusing on precision engineering, superior materials, and rigorous testing, these factories ensure the reliability and efficiency of their products. As industries continue to evolve and face new challenges, the demand for high-quality slurry submersible pumps will only grow, making it essential to invest in the best manufacturing practices. For businesses, choosing pumps from a reputable factory ensures not only operational efficiency but also long-term success in managing challenging fluid transport tasks.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025