Nov . 11, 2024 16:04 Back to list

high quality slurry pump wet end parts manufacturers

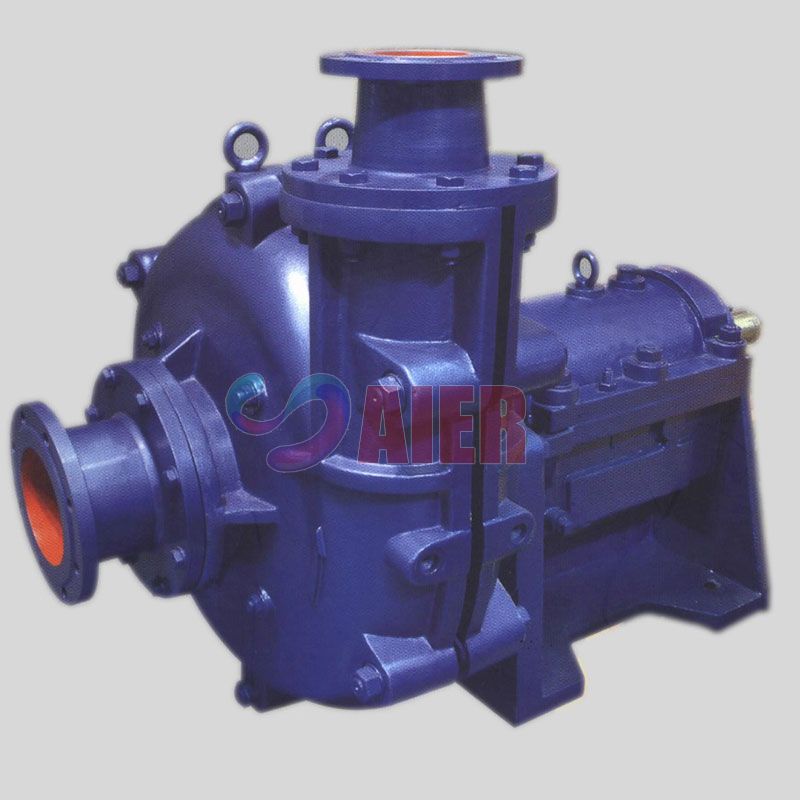

High-Quality Slurry Pump Wet End Parts Manufacturers Ensuring Efficiency and Durability in Pumping Solutions

In the industrial realm, slurry pumps play a crucial role in transferring abrasive and viscous materials, particularly in sectors such as mining, mineral processing, and wastewater treatment. An essential component of the slurry pump system is the wet end, which includes parts such as impellers, casings, and liners. The quality of these wet end parts directly influences the pump's operational efficiency, longevity, and overall performance. Therefore, identifying high-quality slurry pump wet end parts manufacturers is paramount for industries relying on these critical components.

The Importance of High-Quality Wet End Parts

Slurry pumps operate in challenging environments where they are exposed to abrasive slurries at various flow rates and pressures. High-quality wet end parts are designed to withstand the rigors of such operations, reducing the risk of wear and tear and ensuring continuous, reliable performance. High-quality materials and engineering excellence are at the core of effective slurry pump design, enabling pumps to handle abrasive solids without compromising performance.

Key Features of High-Quality Wet End Parts

1. Material Selection The best manufacturers use advanced materials, such as high-chrome iron, rubber, and other durable composites that can resist wear and corrosion. This ensures that the wet end components can endure harsh conditions while maintaining functionality.

2. Precision Engineering High-quality wet end parts are manufactured using state-of-the-art technology and precision engineering techniques. This results in components that fit together perfectly, reducing the likelihood of leaks and improving the overall efficiency of the pump.

3. Adaptability The ability to customize wet end parts to specific engineering requirements allows for better alignment with the operational needs of various industries. Whether it's a specific type of impeller design or a unique casing configuration, top manufacturers offer tailored solutions.

4. Testing and Quality Assurance Leading manufacturers implement rigorous testing protocols to ensure their products meet industry standards. This includes performance tests under extreme conditions to guarantee that components will perform reliably over time.

high quality slurry pump wet end parts manufacturers

Benefits of Sourcing from Reputable Manufacturers

Choosing the right manufacturer for slurry pump wet end parts comes with numerous advantages

- Increased Reliability High-quality parts reduce maintenance costs and downtime, ensuring that pumps operate efficiently for prolonged periods.

- Cost-Effectiveness While high-quality parts may come with a higher initial price, the longevity and reduced need for frequent replacements ultimately lead to cost savings over time.

- Expert Support Established manufacturers often provide expert consultation services, helping companies choose the right components for their specific applications and offering guidance on installation and maintenance.

- Innovation and R&D Renowned manufacturers invest in research and development to continuously enhance their product offerings. This innovation leads to better designs and materials that improve pump performance.

Conclusion

In conclusion, the role of high-quality slurry pump wet end parts manufacturers is integral to the efficiency and effectiveness of slurry pumping operations across various industries. By prioritizing durability, precision, and innovative design, these manufacturers enable companies to overcome the challenges posed by abrasive and viscous materials. As industries continue to evolve, the demand for top-tier slurry pump components will only grow, making it essential for businesses to partner with reputable manufacturers committed to quality and performance. Investing in high-quality wet end parts is not merely an operational decision—it's a strategic move towards enhanced productivity and sustainability in the industrial landscape.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025