Dec . 26, 2024 04:36 Back to list

Top Manufacturer of High-Quality Rubber Spare Parts for Slurry Pumps

High Quality Slurry Pump Spare Parts The Importance of Rubber Parts Manufacturing

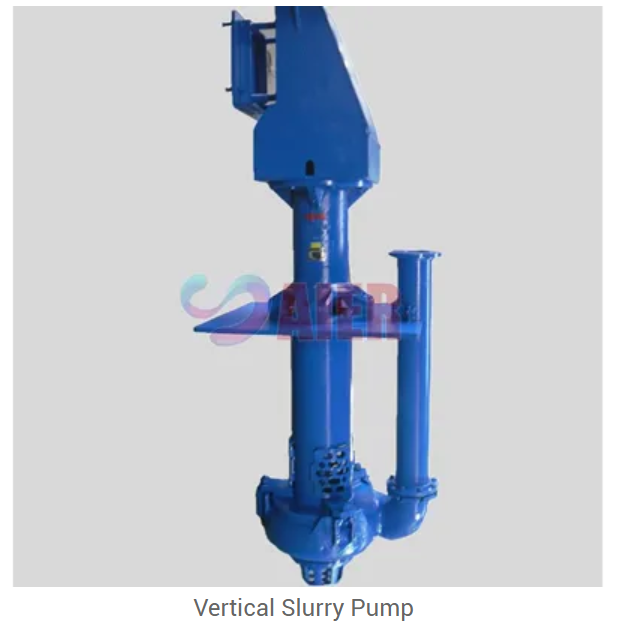

In the world of industrial machinery, slurry pumps play a crucial role in transporting abrasive and viscous materials. These pumps are widely utilized in various sectors, including mining, wastewater treatment, and construction. Given the challenging environments where slurry pumps operate, the need for high-quality spare parts, especially rubber components, cannot be overstated. This article delves into the significance of rubber parts in slurry pumps and the essential considerations in their manufacturing.

Understanding Slurry Pumps and Their Applications

Slurry pumps are designed to handle a mixture of liquid and solid particles, often referred to as slurry. The nature of these materials can be aggressive and can easily wear down pump components. As such, the efficiency and longevity of these pumps rely heavily on the quality of their spare parts. Among these, rubber parts such as impellers, liners, and seals are critical in ensuring optimal performance.

The durability and flexibility of rubber make it an exemplary material for these components. Rubber parts can absorb shocks, withstand wear, and provide chemical stability, which is essential for handling corrosive slurries. High-quality rubber parts minimize the risk of leaks and failures, translating to less downtime and increased productivity.

The Role of Rubber Parts in Slurry Pumps

1. Wear Resistance Rubber has excellent wear resistance compared to metals. In slurry applications where solid particles can cause significant abrasion, rubber components help prolong the service life of the pump. High-quality rubber formulations can withstand the harsh operational conditions better than inferior materials.

2. Flexibility and Seal Integrity One of the primary functions of rubber parts is to provide effective sealing within the pump. Good rubber seals ensure that no slurry escapes, which is crucial for both efficiency and environmental safety. Flexible rubber not only creates a tight seal but also compensates for slight misalignments and vibrations during operation.

3. Chemical Resistance Many slurries contain corrosive substances that can degrade traditional materials. High-quality rubber formulations can be tailored to resist specific chemicals, ensuring that the pump remains functional and does not require frequent repairs or replacements.

high quality slurry pump spare parts rubber parts manufacturer

4. Reduced Noise and Vibration Rubber parts can help in dampening vibrations and noise generated by the pump during operation. This not only creates a more pleasant working environment but also reduces wear on other mechanical components.

Manufacturing Considerations for Quality Rubber Parts

To produce high-quality rubber parts for slurry pumps, manufacturers must adhere to a series of rigorous processes and standards

1. Material Selection The choice of rubber compounds is paramount. Various rubber types, including natural rubber, nitrile, EPDM, and neoprene, exhibit different properties. Selecting the appropriate type based on the specific slurry composition and operating conditions ensures enhanced performance.

2. Precision Engineering High-quality rubber parts must be produced with precise dimensions to ensure proper fit and function. Advanced manufacturing techniques such as injection molding, compression molding, and extrusion can be employed to achieve the necessary specifications.

3. Quality Control A robust quality control process is essential to monitor the properties of the rubber parts throughout the manufacturing cycle. Tests for tensile strength, elasticity, and wear resistance must be conducted to ensure that the final product meets industry standards.

4. Customization Every slurry application has unique requirements. Offering customization options for rubber parts based on the specific needs of customers is a key differentiator for manufacturers. This can include tailored sizing, shape, and material composition.

Conclusion

In summary, the role of high-quality rubber parts in slurry pumps is indispensable. Their ability to withstand harsh conditions, provide effective sealing, and enhance overall pump performance makes them vital components in the industrial sector. For manufacturers, focusing on material quality, precise engineering, and stringent quality control will ensure that their rubber parts meet the high standards required by industries that rely on slurry pumps. By investing in superior rubber parts, businesses can significantly improve the efficiency, reliability, and longevity of their slurry pumping operations, driving overall productivity and success.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025