Nov . 13, 2024 14:35 Back to list

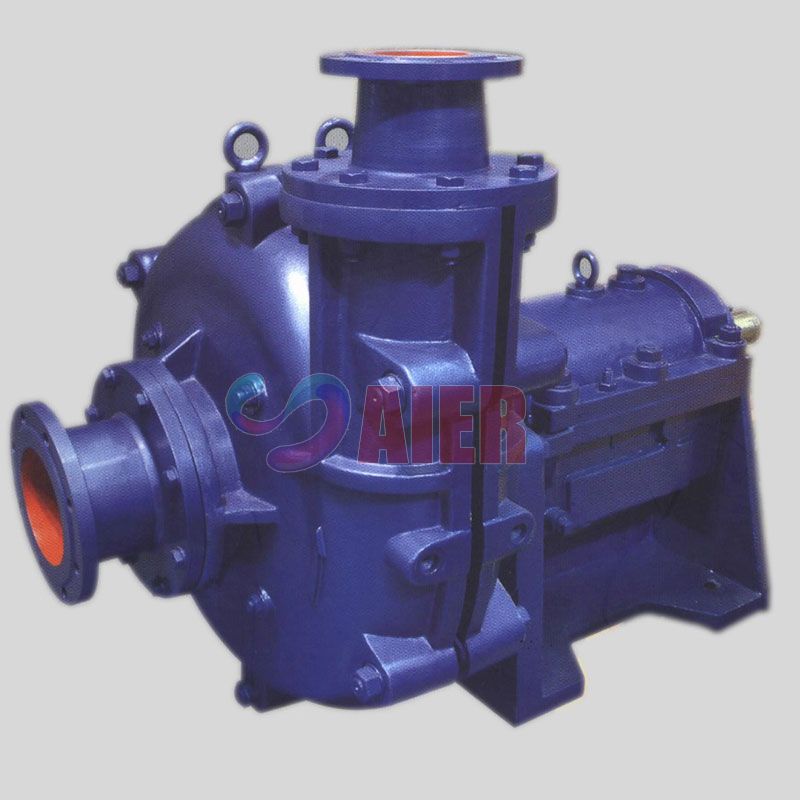

high quality slurry pump seal suppliers

High-Quality Slurry Pump Seal Suppliers Key Considerations

When it comes to industrial applications that involve the transport of abrasive and corrosive materials, slurry pumps play a vital role. These pumps are designed to handle slurries, which are mixtures of solids and liquids, and are commonly used in industries such as mining, construction, and wastewater treatment. A crucial component of slurry pumps is the seal, which prevents leakage and ensures the pump operates effectively. This article explores the importance of sourcing high-quality slurry pump seals and the considerations for selecting the right suppliers.

Understanding Slurry Pump Seals

Slurry pump seals are integral to the performance and longevity of the pump. They serve the essential function of keeping the pumped materials contained within the pump and prevent external contaminants from entering the system. Because they operate in harsh environments, these seals must be resilient, durable, and capable of withstanding varying pressures and temperatures.

The types of seals commonly used in slurry pumps include mechanical seals, packing seals, and lip seals. Each type has its own advantages and is suited for different applications. For instance, mechanical seals, while more expensive, offer superior resistance to abrasion and can extend the life of the pump significantly. On the other hand, packing seals are simpler and easier to maintain but may require more frequent replacements.

Importance of High-Quality Suppliers

Selecting a high-quality slurry pump seal supplier is essential for several reasons

1. Reliability A reputable supplier ensures that their seals are manufactured to the highest standards. This reduces the risk of equipment failure, which can lead to costly downtime and repairs.

2. Performance High-quality seals can improve the overall performance of the slurry pump by reducing leakage and enhancing efficiency. This means that the pump can operate at optimal levels longer, resulting in better productivity.

3. Cost-effectiveness While high-quality seals may have a higher upfront cost, they often lead to lower long-term maintenance and replacement costs. Investing in quality seals can save money over time by reducing the frequency of repairs and replacements.

high quality slurry pump seal suppliers

4. Technical Support A reliable supplier typically offers additional services, such as technical support and advice on the best sealing solutions for specific applications. This expertise can be invaluable for businesses looking to optimize their pumping systems.

Key Considerations When Choosing Suppliers

When searching for high-quality slurry pump seal suppliers, consider the following factors

1. Reputation in the Industry Research the supplier's reputation by reading reviews, asking for referrals, and checking industry certifications. A supplier with a proven track record in providing high-quality seals is more likely to meet your requirements.

2. Quality Assurance Inquire about the quality control processes the supplier has in place. Accreditation to international standards (e.g., ISO certifications) can be a good indicator of quality.

3. Range of Products A good supplier should offer a variety of sealing solutions to accommodate different slurry pump models and operating environments. This variety allows you to find the right seal for your specific needs.

4. Customization Options Different applications may require customized seal designs. Look for suppliers willing to work with you to develop solutions tailored to your specific operational requirements.

5. After-Sales Support Good after-sales support is crucial. Ensure that the supplier provides assistance with installation, maintenance, and troubleshooting to help you get the most out of your investment.

Conclusion

In conclusion, high-quality slurry pump seals are vital for the efficient and reliable operation of slurry pumps. Selecting the right supplier involves careful consideration of their reputation, product range, and quality assurance processes. By prioritizing these factors, businesses can ensure optimal performance and durability of their slurry pumping systems, ultimately contributing to enhanced productivity and reduced operational costs. Investing in high-quality seals from reputable suppliers is not just a purchase; it is a strategic decision that can yield significant returns over time.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025