Feb . 16, 2025 14:17 Back to list

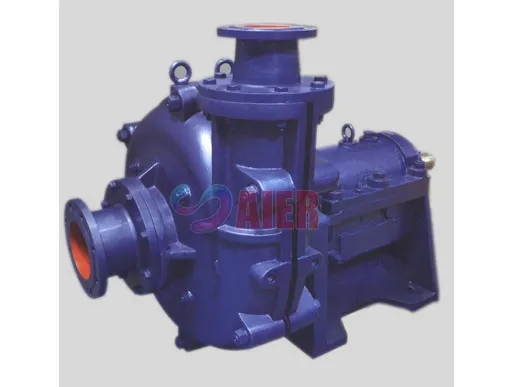

high quality slurry pump impeller type

The global industrial landscape owes much of its efficiency and productivity to the various components that make up the machines driving everyday processes. Among these vital components is the slurry pump impeller, specifically high-quality types that are essential for industries that deal with abrasive and corrosive substances. Understanding their importance requires evaluating their design, material composition, and applications, which reflect the Experience, Expertise, Authoritativeness, and Trustworthiness crucial for selecting the right impeller.

Manufacturers and suppliers of slurry pumps who postulate authority in this field often adhere to stringent quality assurance and testing protocols, setting their impellers apart. They offer comprehensive solutions that include customizable designs tailored to specific operational demands. Trusted brands conduct regular customer feedback sessions and implement cutting-edge technology enhancements, from CFD analyses for flow optimization to incorporating IoT for predictive maintenance strategies. Such practices not only fortify product reliability but also build trustworthy manufacturer-client relationships grounded in transparency and consistent performance validation. Professionals in the field endorsing the choice of high-quality impellers emphasize conducting thorough assessments of application requirements—evaluating solids size and concentration, slurry viscosity, and corrosive properties. It is these measured evaluations and expert recommendations that assure the right impeller choice, bridging the gap between theoretical knowledge and practical application. Consulting engineers and industry veterans advocate selecting impellers from reputable sources, backed by robust certifications and demonstrable track records, ensuring investments promise not just immediate efficiency but long-term sustainability. In conclusion, the secret to maximizing slurry pump operations lies in the conscientious selection of high-quality impeller types. Prioritizing design integrity, material robustness, and reputable sources guarantees not only peak performance but also embodies the pillars of Experience, Expertise, Authoritativeness, and Trustworthiness. As industries continue to evolve, those that embrace advanced impeller technology will invariably lead in operational efficiency and profitability, setting new benchmarks in their respective domains.

Manufacturers and suppliers of slurry pumps who postulate authority in this field often adhere to stringent quality assurance and testing protocols, setting their impellers apart. They offer comprehensive solutions that include customizable designs tailored to specific operational demands. Trusted brands conduct regular customer feedback sessions and implement cutting-edge technology enhancements, from CFD analyses for flow optimization to incorporating IoT for predictive maintenance strategies. Such practices not only fortify product reliability but also build trustworthy manufacturer-client relationships grounded in transparency and consistent performance validation. Professionals in the field endorsing the choice of high-quality impellers emphasize conducting thorough assessments of application requirements—evaluating solids size and concentration, slurry viscosity, and corrosive properties. It is these measured evaluations and expert recommendations that assure the right impeller choice, bridging the gap between theoretical knowledge and practical application. Consulting engineers and industry veterans advocate selecting impellers from reputable sources, backed by robust certifications and demonstrable track records, ensuring investments promise not just immediate efficiency but long-term sustainability. In conclusion, the secret to maximizing slurry pump operations lies in the conscientious selection of high-quality impeller types. Prioritizing design integrity, material robustness, and reputable sources guarantees not only peak performance but also embodies the pillars of Experience, Expertise, Authoritativeness, and Trustworthiness. As industries continue to evolve, those that embrace advanced impeller technology will invariably lead in operational efficiency and profitability, setting new benchmarks in their respective domains.

Latest news

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025