Dec . 09, 2024 17:22 Back to list

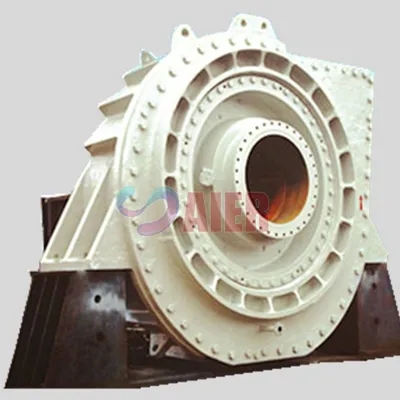

High Efficiency Slurry Pump Expeller for Optimal Fluid Transfer Performance and Reliability

High-Quality Slurry Pump Expellers Essential Tools for Efficient Fluid Management

In industrial applications where the transportation of slurries—that is, semi-liquid mixtures consisting of solid particles suspended in a fluid—is common, high-quality slurry pump expellers play a vital role. These devices are engineered to facilitate the efficient movement of slurries, which can be inherently abrasive, viscous, and challenging to handle. Understanding the functionality, benefits, and selection criteria for high-quality slurry pump expellers is essential for industries relying on fluid and solid handling processes.

Understanding Slurry Pump Expellers

A slurry pump expeller works by utilizing a combination of centrifugal force and an elaborate design to move slurries through pipelines or various processing equipment. Unlike traditional pumps, which may falter under the abrasive nature of slurries, high-quality slurry pump expellers are specifically designed for the rigors of heavy-duty applications. Their components, including the impeller and casing, are often constructed from wear-resistant materials, ensuring longevity and consistent performance.

Key Features of High-Quality Slurry Pump Expellers

1. Robust Construction The materials used in manufacturing slurry pump expellers are crucial. High-quality expellers often feature stainless steel, high-chrome alloys, or elastomers that resist wear and corrosion, increasing the lifespan of the pump.

2. Variable Speed Capabilities Many modern slurry pumps come with variable speed drives, allowing for adjustments based on the specific requirements of the slurry being handled. This adaptability can lead to enhanced efficiency and reduced energy consumption.

3. High Efficiency Quality slurry pump expellers are designed to minimize energy losses during operation. Their engineering considers flow dynamics to ensure that slurries are moved with minimal energy expenditure.

4. Easy Maintenance High-quality designs facilitate easy maintenance, allowing quick access to impellers and other critical components. This ease of maintenance reduces downtime and associated costs.

5. Versatility and Customization Leading manufacturers often provide customizable slurry pump expellers that can be tailored to the specific needs of the application, accommodating various types of slurries, including those found in mining, wastewater treatment, and agriculture.

Applications of Slurry Pump Expellers

Slurry pump expellers find widespread application across several industries

high quality slurry pump expeller

- Mining In mining operations, these pumps are essential for transporting slurry produced during ore extraction and processing. Their durability ensures that they can handle heavy, abrasive materials typical in this industry.

- Construction In construction, slurry pumps are often used to manage sediment-laden water, especially on sites dealing with concrete and excavation activities.

- Wastewater Treatment These pumps are invaluable in wastewater treatment plants, where they move sludge and other waste materials for processing and disposal.

- Chemical Processing In the chemical industry, slurry pump expellers facilitate the movement of hazardous materials mixed in liquid forms, where reliability and safety are paramount.

Selecting the Right Slurry Pump Expeller

When choosing a high-quality slurry pump expeller, several factors must be considered

- Pump Size The size of the pump should match the specific application’s capacity requirements, taking into account both the volume of slurry and its characteristics.

- Particle Size The design of the expeller must accommodate the size of solid particles in the slurry to avoid blockages and ensure smooth operation.

- Flow Rate Understanding the required flow rate is critical. An appropriate pump should be able to deliver the desired flow while maintaining operational efficiency.

- Operating Conditions Factors such as temperature, viscosity, and pH levels of the slurry can affect the choice of materials used in the pump’s construction.

Conclusion

High-quality slurry pump expellers are indispensable for industries dealing with challenging fluid transfers. Their robust construction, efficiency, and versatility can significantly impact operational effectiveness and cost management. By understanding the features and applications of these pumps, businesses can make informed decisions that enhance productivity and ensure the safe transport of slurries in various industrial processes. Investing in quality slurry pump expellers is an investment in efficiency, reliability, and long-term operational success.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025