Nov . 05, 2024 20:14 Back to list

high quality slurry pump components supplier

High-Quality Slurry Pump Components Supplier Meeting Industry Demands

In the world of industrial operations, slurry pumps play a crucial role, particularly in sectors such as mining, construction, and wastewater management. These pumps are designed to handle abrasive, viscous, and corrosive materials efficiently. However, the performance and longevity of a slurry pump largely depend on the quality of its components. This is where a high-quality slurry pump components supplier becomes vital in ensuring operational excellence and productivity.

Importance of Quality Components

Slurry pumps are subject to harsh environmental conditions and heavy wear and tear due to the materials they transport. Poor-quality components can lead to frequent breakdowns, increased maintenance costs, and downtime, which ultimately affects productivity and profitability. Therefore, sourcing from a reputable supplier that specializes in high-quality slurry pump components is imperative. A reliable supplier offers components made from durable materials that can withstand abrasion and corrosion, ensuring the pump operates efficiently over a longer lifespan.

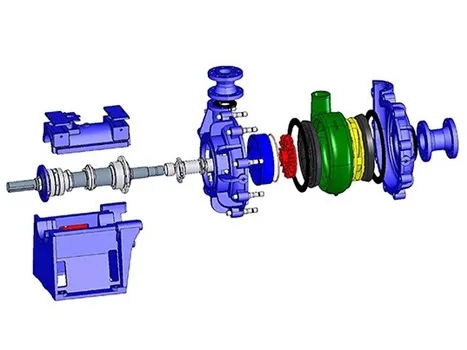

Key Components of Slurry Pumps

1. Impellers The impeller is the heart of the slurry pump, responsible for converting mechanical energy into hydraulic energy. High-quality impellers are essential, as they significantly impact the pump’s efficiency. Suppliers provide a range of impeller designs tailored to different slurry types and operational conditions.

2. Casing The casing encloses the impeller and helps maintain pressure. Using high-strength materials for the casing can prevent leaks and protect against damage from abrasive particles. A reliable supplier offers casings that are both robust and lightweight, optimizing the pump's performance.

3. Shafts and Bearings These components are critical for ensuring smooth operation. High-quality shafts and bearings reduce friction and wear, thereby enhancing the pump's durability. Suppliers that prioritize material quality can ensure these components can withstand high stress and loads.

high quality slurry pump components supplier

4. Seals and Gaskets Proper sealing is crucial for preventing leaks and contamination of the slurry. High-quality seals and gaskets can handle extreme temperatures and pressures. Choosing a supplier that specializes in sealing technology ensures that pumps remain operational without the risk of fluid loss or damage.

Selecting a Supplier

When looking for a high-quality slurry pump components supplier, it is essential to consider several factors

- Experience and Reputation A supplier with years of experience and a solid reputation in the industry is more likely to provide reliable products. - Customization Options Since different industries have varying requirements, a supplier that offers tailored solutions can better meet specific needs. - Quality Assurance Look for suppliers who adhere to industry standards and possess certifications indicating their commitment to quality.

- Technical Support A good supplier should provide excellent customer service, including support for installation, maintenance, and troubleshooting.

Conclusion

In conclusion, the performance of slurry pumps largely depends on the quality of their components. Investing in high-quality slurry pump components from a reputable supplier ensures operational efficiency, reduces maintenance costs, and extends the lifespan of the equipment. As industries continue to evolve and demand more from their machinery, the significance of choosing the right supplier cannot be overstated. Whether in mining, construction, or wastewater management, having a reliable supplier for slurry pump components is essential for success in today's competitive environment. Investing time and resources in selecting the best supplier will pay off substantially in terms of reliability, efficiency, and productivity.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025