Nov . 08, 2024 01:55 Back to list

Reliable Durable Submersible Slurry Pump Manufacturers for Heavy Duty Applications

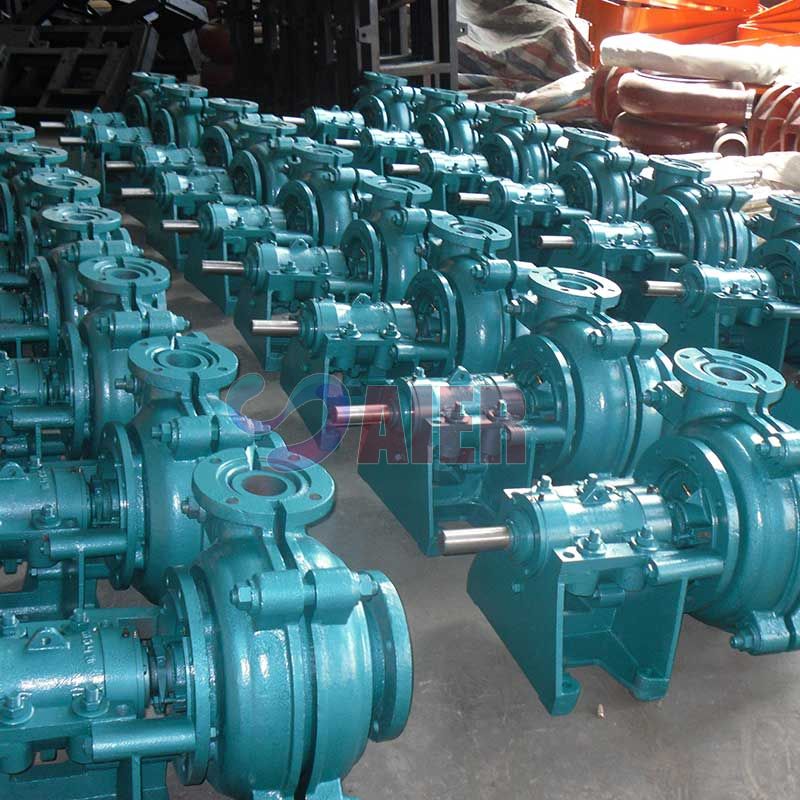

High-Quality Heavy-Duty Submersible Slurry Pump Suppliers

Submersible slurry pumps are essential machinery used in various industries, including construction, mining, and wastewater management. These pumps are designed to handle the transfer of abrasive, viscous, and heavy slurries. Due to the demanding nature of their applications, high-quality heavy-duty submersible slurry pumps are critical. This article explores what to look for in suppliers of these pumps and why quality is paramount for ensuring efficiency and longevity.

When selecting a supplier for heavy-duty submersible slurry pumps, the quality of the products should be the foremost consideration. High-quality pumps are constructed from robust materials capable of withstanding the harsh environments in which they operate. Common materials include high-chrome alloys and stainless steel, which resist corrosion and wear. Such durability ensures that pumps can function effectively over prolonged periods, reducing the need for frequent replacements and maintenance.

In addition to material quality, the design of the pumps plays a significant role in their effectiveness. Reputable suppliers invest in advanced engineering and technology, leading to better hydraulic performance and energy efficiency. An efficient pump reduces operational costs and can handle varying flow rates and head requirements. When researching suppliers, it is essential to review their product specifications and engineering capabilities to ensure they meet industry standards and performance expectations.

Furthermore, a supplier’s reputation is critical in determining the reliability of their products. Established suppliers often have a history of delivering high-quality pumps to various industries and possess a portfolio that showcases their expertise. Customer reviews and testimonials can provide valuable insights into the performance and longevity of the pumps, as well as the level of post-purchase support offered. Engaging with past clients or reading detailed case studies can assist in making an informed choice.

high quality heavy duty submersible slurry pump suppliers

Another aspect to consider is the availability of customized solutions. In many applications, standard pumps may not meet specific requirements. Leading suppliers often offer customization options to tailor pumps according to unique field conditions and client needs. This adaptability is crucial in applications involving varying viscosity, temperature, and chemical composition of slurries. A supplier that can provide tailored solutions demonstrates a commitment to understanding and addressing client challenges.

The level of after-sales service is equally important when selecting a supplier. Quality submersible slurry pumps may require regular maintenance, and having a supplier that provides comprehensive support and service can make a significant difference. A supplier that offers warranties, spare parts availability, and maintenance services enhances the overall value of the pump purchase. Clients can benefit from professional advice on installation, operation, and troubleshooting from experienced technicians.

Cost is an inevitable factor in decision-making, but it should not be the sole criterion. While attractive pricing can be tempting, it is essential to evaluate the trade-off against quality and performance. Investing in a reliable pump that delivers superior performance often leads to long-term savings. High-quality pumps tend to have enhanced efficiency and require less energy to operate, which can substantially lower operational costs over time.

Finally, in today’s environmentally conscious market, selecting a supplier that prioritizes sustainability can be advantageous. Many reputable suppliers manufacture pumps using eco-friendly practices and materials. Consideration of environmental impact not only reflects a company’s ethics but can also align with the sustainable goals of many industries.

In conclusion, when looking for high-quality heavy-duty submersible slurry pump suppliers, it is crucial to prioritize product quality, supplier reputation, customization options, after-sales service, cost-effectiveness, and sustainability. By taking the time to thoroughly research and assess potential suppliers, businesses can ensure they make informed decisions that lead to optimal operational efficiency and reliability in their slurry handling processes. Choosing the right supplier is an investment that pays dividends in performance and peace of mind.

-

Top China Submersible Slurry Pump Supplier Durable & Efficient Solutions

NewsMay.17,2025

-

Submersible Pump Spares Manufacturer High-Quality & Durable Components

NewsMay.17,2025

-

Vertical Centrifugal Sump Pump Supplier China Factory Solutions

NewsMay.16,2025

-

Vertical Spindle Slurry Pump Suppliers High-Quality China Manufacturers

NewsMay.16,2025

-

High-Quality Casting Submersible Pump Parts Manufacturer Durable Solutions

NewsMay.16,2025

-

Vertical Sump & Mud Screw Slurry Pump Company Durable Solutions

NewsMay.15,2025