Feb . 16, 2025 11:14 Back to list

G10083A05 high chrome throatbush

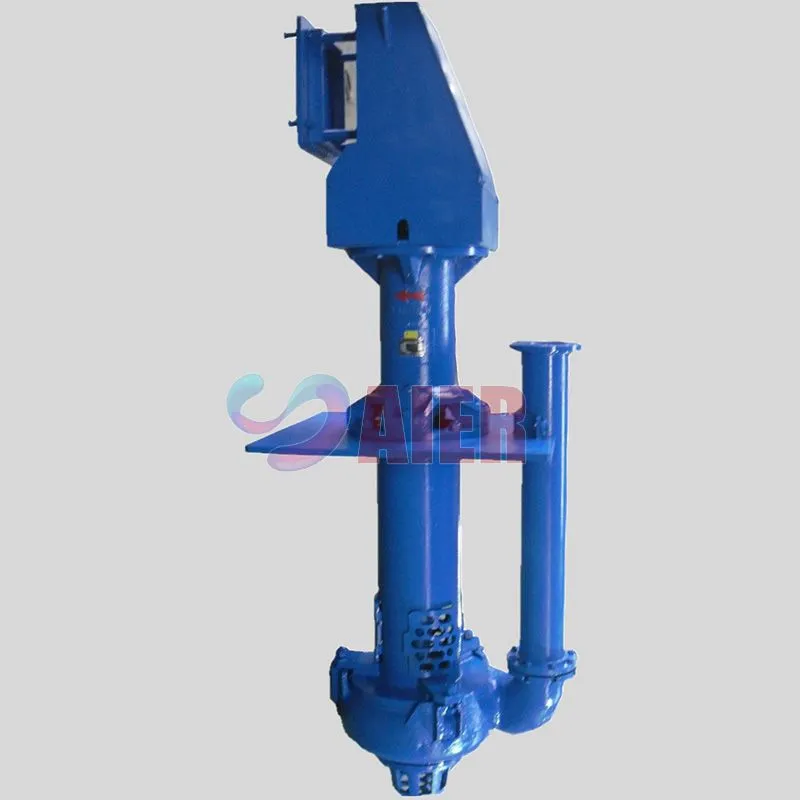

If you’re in the market for a high quality heavy duty submersible pump, understanding the essential features and applications of these devices can be the decisive factor in making an informed purchase. Submersible pumps, defined by their custom capability to operate beneath the surface of the liquid being pumped, are fundamental in various industries due to their high efficiency and reliability under demanding conditions.

For a credible heavy duty submersible pump selection, brand reputation and customer experiences offer critical insights. Manufacturers with a track record of reliability and service excellence build trust through transparent warranties and available certified service options. It is advisable to prioritize established brands recognized within the industrial sectors, as their submersible pumps often exhibit superior performance and durability. Field experience verifies the importance of these pumps in real-world scenarios. Operators praise their reduced operational noise, thanks to an underwater operation that limits sound pollution and vibration. Furthermore, the energy efficiency of submerged pumps often surpasses above-ground alternatives, minimizing power consumption and consequently reducing operational costs. The sealed design also eliminates the risk of cavitation – a common issue faced by non-submersible pumps, further fortifying their reliability. Selecting the ideal submersible pump involves a balance of technical specifications and practical testimonials. It requires a meticulous assessment of flow and head requirements, power supply compatibility, and service conditions. The trust placed in a submersible pump stems from its ability to consistently perform under pressure, a testament to meticulous design, sturdy construction, and adaptive functionality. Ultimately, the investment in a high quality heavy duty submersible pump ensures operational efficiency, safety, and peace of mind, cementing its role as an indispensable asset in liquid management and movement.

For a credible heavy duty submersible pump selection, brand reputation and customer experiences offer critical insights. Manufacturers with a track record of reliability and service excellence build trust through transparent warranties and available certified service options. It is advisable to prioritize established brands recognized within the industrial sectors, as their submersible pumps often exhibit superior performance and durability. Field experience verifies the importance of these pumps in real-world scenarios. Operators praise their reduced operational noise, thanks to an underwater operation that limits sound pollution and vibration. Furthermore, the energy efficiency of submerged pumps often surpasses above-ground alternatives, minimizing power consumption and consequently reducing operational costs. The sealed design also eliminates the risk of cavitation – a common issue faced by non-submersible pumps, further fortifying their reliability. Selecting the ideal submersible pump involves a balance of technical specifications and practical testimonials. It requires a meticulous assessment of flow and head requirements, power supply compatibility, and service conditions. The trust placed in a submersible pump stems from its ability to consistently perform under pressure, a testament to meticulous design, sturdy construction, and adaptive functionality. Ultimately, the investment in a high quality heavy duty submersible pump ensures operational efficiency, safety, and peace of mind, cementing its role as an indispensable asset in liquid management and movement.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

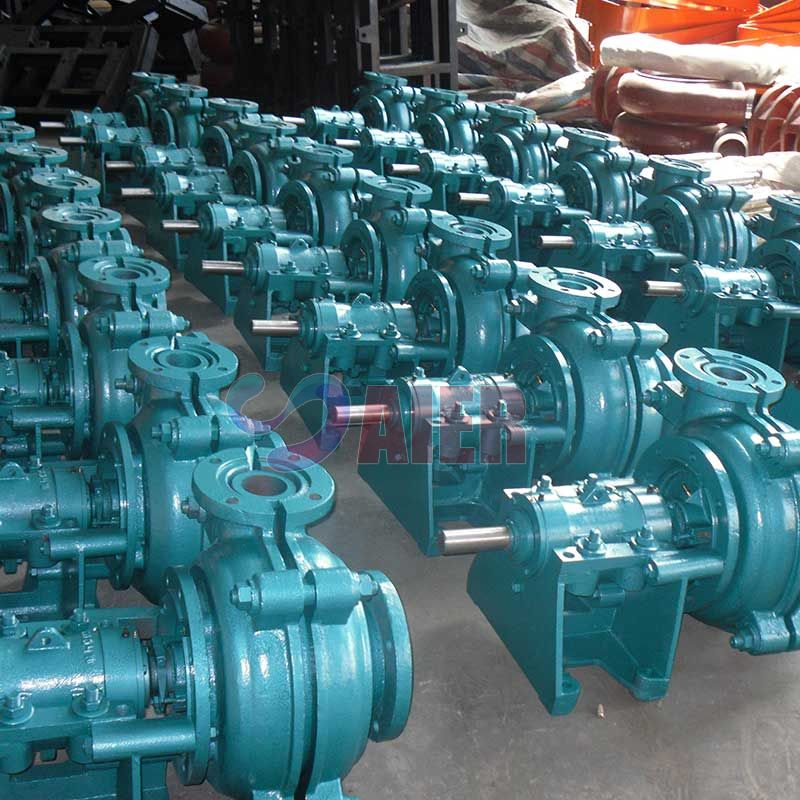

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025