Dec . 06, 2024 10:28 Back to list

Top-rated submersible slurry pump manufacturers for high-performance and durable solutions

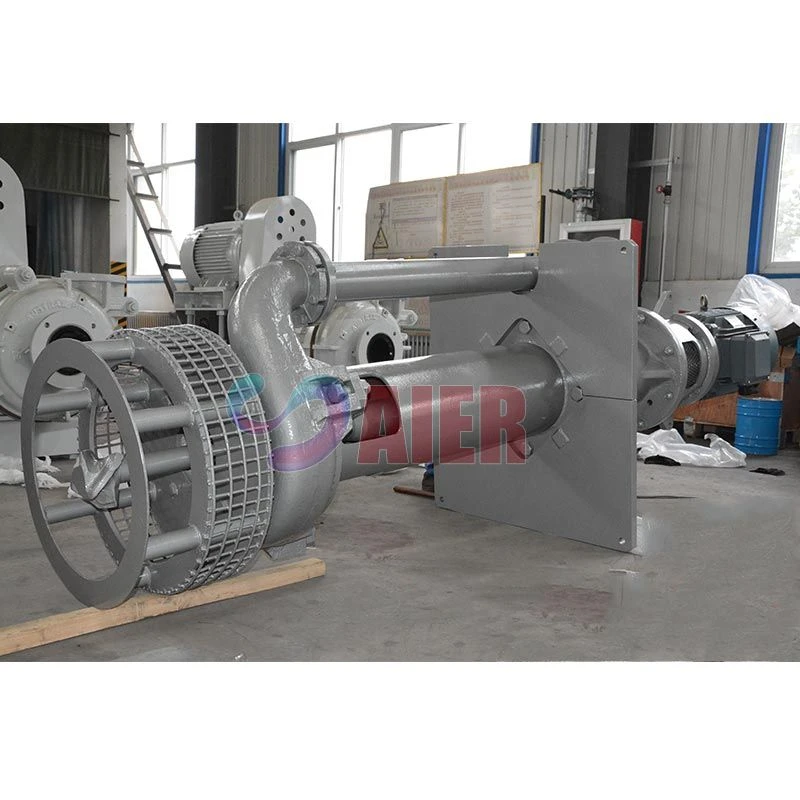

High Quality Good Submersible Slurry Pump Manufacturer

Submersible slurry pumps are essential tools in various industrial applications, especially in mining, construction, and wastewater management. These pumps are designed to handle thick, abrasive fluids, making them crucial for transporting slurry efficiently and effectively. As the demand for these pumps grows, the need for high-quality manufacturers has become increasingly vital. In this article, we will explore what constitutes a good submersible slurry pump manufacturer and what to look for when selecting one.

Understanding Submersible Slurry Pumps

Submersible slurry pumps are unique in their design and functionality. These pumps are submerged in the liquid they are pumping, which eliminates the need for priming and allows for better efficiency. They are built to handle solid particles, sludge, and thick slurries that traditional pumps might struggle with. Due to the nature of their operation, these pumps must be robust, reliable, and capable of enduring challenging environments.

Key Features of High-Quality Submersible Slurry Pumps

1. Durability The materials used in the construction of submersible slurry pumps play a crucial role in their durability. High-quality pumps typically use hardened steel or other wear-resistant materials that can withstand abrasive slurries, reducing the likelihood of wear and tear.

2. Efficient Hydraulic Design The design of the pump's impeller and volute is essential for efficiency. A well-engineered hydraulic system will ensure optimal flow rates and energy consumption, allowing for high productivity while minimizing operational costs.

3. Powerful Motor The motor must be strong enough to handle the viscosity and density of the slurry being pumped. A reputable manufacturer will provide pumps with motors that are energy-efficient and capable of operating in challenging conditions.

4. Ease of Maintenance High-quality pumps are designed for easy maintenance. This includes features such as quick access panels, removable parts, and modular designs that facilitate repairs and part replacements.

5. Reliability A good manufacturer will focus on the reliability of their pumps. This is often demonstrated through rigorous testing and quality control processes, ensuring that the pumps perform consistently over time.

Choosing a Manufacturer

high quality good submersible slurry pump manufacturer

When it comes to selecting a high-quality submersible slurry pump manufacturer, there are several factors to consider

1. Reputation Look for manufacturers with a solid reputation in the industry. They should have a track record of providing reliable products and excellent customer service.

2. Experience Manufacturers with years of experience are likely to have gained valuable insights into pump design and production. This experience often translates to better-quality products.

3. Customization A good manufacturer should be able to offer tailored solutions to meet specific needs. Customized pumps can greatly enhance efficiency and productivity in unique applications.

4. Certification and Standards Check if the manufacturer adheres to relevant certification standards and regulations. Certifications, such as ISO, indicate a commitment to quality and safety.

5. After-Sales Support Reliable manufacturers provide robust after-sales support, including maintenance services, spare parts availability, and technical assistance.

The Importance of Quality Control

Quality control is a critical aspect of manufacturing submersible slurry pumps. High-quality manufacturers implement stringent quality assurance processes throughout production. This includes sourcing the best materials, investing in advanced manufacturing technologies, and conducting thorough testing of the pumps before they leave the factory. By prioritizing quality control, manufacturers help ensure that their pumps meet industry standards and customer expectations.

Conclusion

In conclusion, selecting a high-quality submersible slurry pump manufacturer is essential for ensuring the efficiency and effectiveness of slurry transport systems. By focusing on the key features of durable and reliable pumps, the selection process can be streamlined. Additionally, by choosing a reputable manufacturer with a robust track record, you can ensure that you invest in a pump that meets your operational needs. The right choice will not only improve productivity but also reduce maintenance costs and extend the lifespan of the equipment, driving overall success in your operations.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025