Nov . 06, 2024 03:18 Back to list

Top Manufacturers of High-Performance Centrifugal Slurry Pump Replacement Parts

High-Quality Centrifugal Slurry Pump Spare Parts Manufacturers

In industries such as mining, mineral processing, and chemical manufacturing, the effectiveness of equipment often hinges on the reliability of their components. Among these, centrifugal slurry pumps play a crucial role in transporting abrasive, thick, or viscous materials. The longevity and efficiency of these pumps heavily depend on the quality of their spare parts. Therefore, sourcing high-quality spare parts from reputable manufacturers becomes paramount.

The Importance of Quality Spare Parts

Centrifugal slurry pumps are designed to handle tough materials, but wear and tear are inevitable over time. High-quality spare parts can significantly prolong the life of pumps by maintaining their operational efficiency and reducing downtime. Poor-quality components may lead to frequent breakdowns, costly repairs, and operational inefficiencies. In contrast, high-quality parts ensure optimal performance, enhance energy efficiency, and provide a better return on investment.

Key Features of Quality Manufacturers

When searching for high-quality centrifugal slurry pump spare parts manufacturers, certain key features should be taken into account

1. Material Quality One of the primary indicators of a manufacturer’s commitment to quality is the materials used in their products. High-quality spare parts should be made from durable materials that can withstand harsh conditions. This includes heavy-duty metals and elastomers that resist corrosion, abrasion, and wear.

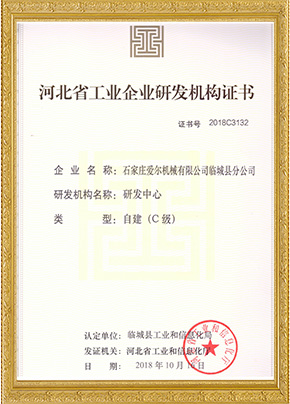

2. Certification and Compliance Reputable manufacturers often hold certifications that validate their adherence to industry standards and best practices. Certifications from organizations such as ISO can serve as a benchmark for evaluating the reliability and quality assurance processes of a manufacturer.

high quality centrifugal slurry pump spare parts manufacturers

3. Technological Advancements The best manufacturers continually invest in research and development to improve their products. Advanced technologies can enhance the design and manufacturing processes, resulting in superior spare parts that meet the evolving needs of the industry.

4. Customization Capabilities Each application may require specific configurations and components. Quality manufacturers typically offer customization options to ensure that the spare parts meet the unique requirements of different slurry pump models and operating conditions.

5. Customer Support and Service A reliable manufacturer not only provides quality parts but also offers exceptional customer service. This includes technical support, guidance on installation, and assistance with any issues that may arise post-purchase. A proactive customer service approach can greatly enhance the overall experience and satisfaction.

Leading Manufacturers in the Industry

Several manufacturers stand out in the realm of high-quality centrifugal slurry pump spare parts. Companies with a long-standing presence in the market and a reputation for excellence often have a comprehensive range of parts, including impellers, casings, liners, and seals. These manufacturers utilize state-of-the-art technologies and rigorous quality control measures to ensure that every spare part meets stringent performance standards.

Furthermore, many of these leading manufacturers prioritize sustainability by implementing environmentally friendly practices in their production processes. This is not only beneficial for the environment but also aligns with the growing focus on sustainable practices across industries.

Conclusion

In conclusion, sourcing high-quality centrifugal slurry pump spare parts from reputable manufacturers is essential for ensuring the efficient and reliable operation of slurry pumps. By focusing on material quality, compliance, technological advancements, customization, and customer support, industries can significantly enhance their operational efficiency and minimize downtime. In today’s competitive landscape, investing in superior components will ultimately lead to a more sustainable and profitable operation.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025