Nov . 08, 2024 17:26 Back to list

high quality best pump for lime slurry manufacturer

Choosing the Best High-Quality Pump for Lime Slurry A Comprehensive Guide

When it comes to handling lime slurry, the choice of pump is critical to ensure efficiency, durability, and performance. Lime slurry is widely used in various industries, particularly in water treatment, mining, and construction. Its caustic nature, along with its solid content, poses unique challenges for pumping systems. Therefore, selecting a high-quality pump designed specifically for lime slurry is essential for optimizing operations and minimizing downtime.

Understanding Lime Slurry

Lime slurry typically consists of calcium hydroxide mixed with water and is used for several purposes, including pH adjustment, water clarification, and as a reagent in chemical processes. Given its alkaline nature, the slurry can be abrasive and corrosive, which necessitates the use of specially designed pumps that can withstand these harsh conditions.

Key Features of a High-Quality Lime Slurry Pump

1. Material Construction The pump must be made from high-quality materials that resist corrosion and abrasion. Common materials include stainless steel, various grades of rubber, and specialized alloys. The wetted parts of the pump should be designed to handle the properties of lime slurry effectively.

2. Pump Type Different pump types offer varied advantages. Centrifugal pumps, for instance, are suitable for low-viscosity applications, while positive displacement pumps may be more appropriate for high-viscosity lime slurry. The specific application and the characteristics of the slurry, such as solid content and particle size, will greatly influence the choice of pump.

3. Performance Efficiency A well-designed pump will provide optimal flow rates and pressure capabilities. It's vital to select a pump that can maintain high efficiency even under the specified operating conditions to reduce energy consumption and operating costs.

high quality best pump for lime slurry manufacturer

4. Maintenance Accessibility Pump maintenance is a critical aspect of ensuring long-term performance. A high-quality pump should allow for easy access to components for routine maintenance, cleaning, and part replacement. This accessibility contributes to less downtime and helps extend the life of the pump.

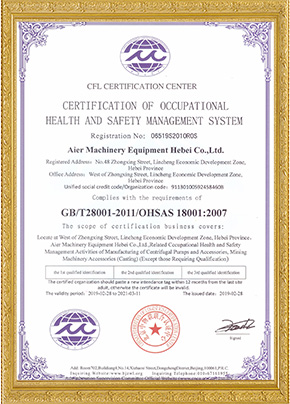

5. Manufacturer Reputation Choosing a reputable and established manufacturer can sometimes be as important as the pump's specifications. Manufacturers with a proven track record in the industry will typically provide better support, warranties, and spare parts, ensuring that you have a reliable solution for your pumping needs.

The Importance of Testing and Specifications

When selecting a pump for lime slurry, it’s crucial to review the technical specifications and test results. Manufacturers should provide comprehensive data regarding the pump’s performance under various conditions, including flow rate, pressure limits, and fluid compatibility. Additionally, testing the pump on-site with actual lime slurry can help identify any potential issues before full-scale implementation.

Conclusion

Selecting the best high-quality pump for lime slurry is a vital investment for any industry utilizing this material. By considering factors such as material construction, pump type, performance efficiency, maintenance requirements, and manufacturer reputation, businesses can make informed purchasing decisions that enhance operational efficiency and ensure long-term success. Prioritizing these aspects will not only improve the effectiveness of the pumping system but also contribute to overall process reliability and sustainability.

In summary, whether you are involved in water treatment, mining, or construction, ensuring that you have the right pump for your lime slurry application is paramount. Opt for a pump built to handle the challenges of lime slurry with superior materials and technology, and you will be set on a path toward operational excellence.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025